Hatch coaming closing and hoisting method

A hoisting method and hatch enclosure technology, which can be used in transportation and packaging, ship parts, ships, etc., and can solve the problems of affecting the berth cycle, low efficiency, and high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

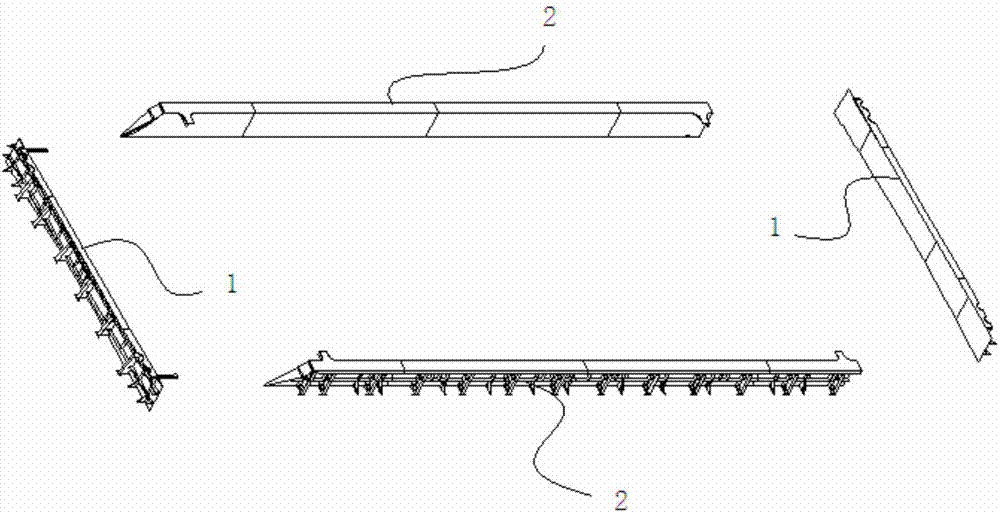

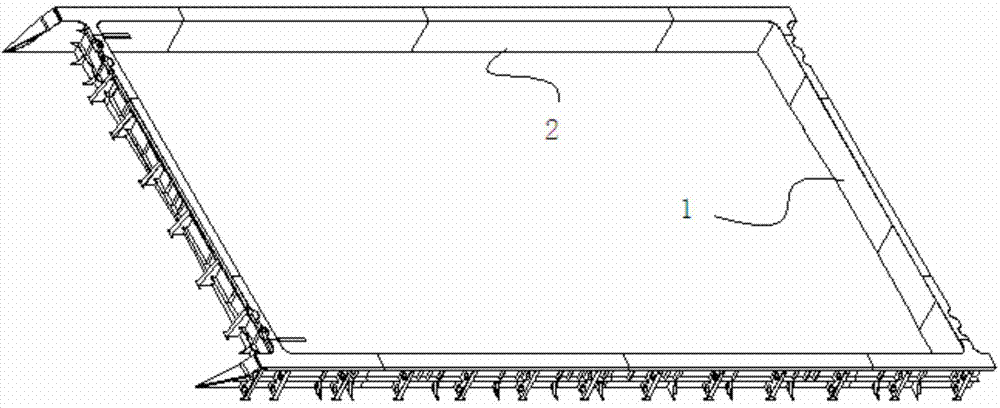

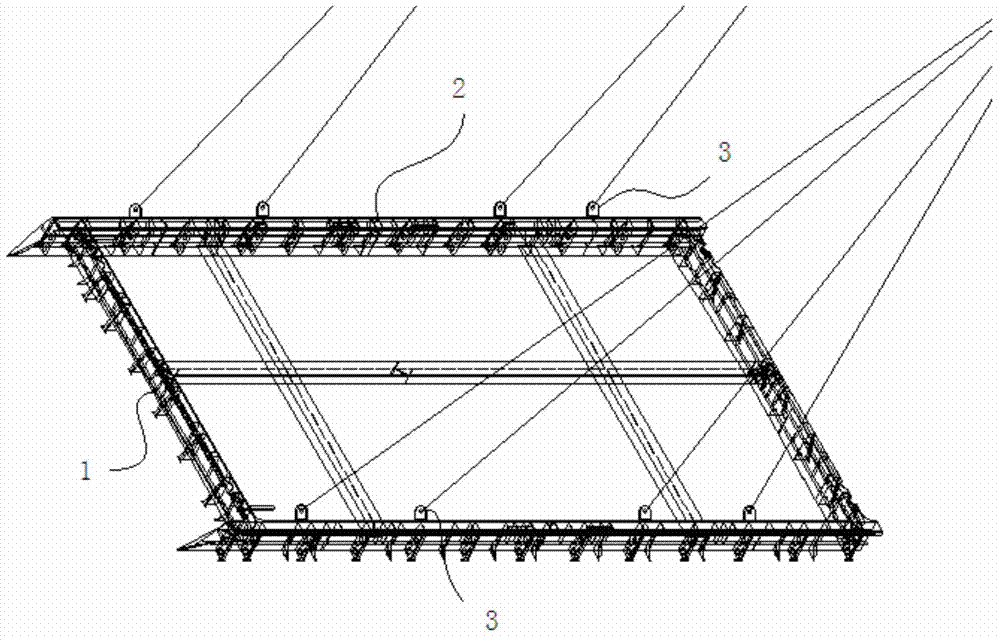

[0028] This embodiment takes a 15,000-ton bulk carrier as an example, which has three cargo holds in total, and the opening size of each cargo hold is 19,000X33,400. Each side of the hatch enclosure is divided into two pieces, each cabin has 8 pieces in total, and the weight is about 55 tons (except for pipe and outfitting electrical parts); after the hatch enclosure is hoisted as a whole, each hatch enclosure only needs to be hoisted once, which can reduce 23 hoisting times. Reduced berth cycle.

[0029] The hatch enclosure closing and hoisting method of the present invention comprises the following steps:

[0030] Measurement steps, measuring various data of the hatch coaming and the deck on which it is located, these data include: the actual length, width, height, diagonal line of the hatch coaming and the distance between the ribs of the closing mouth, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com