Automobile hub packing line conveying device

A technology of conveying device and automobile wheel hub, applied in packaging and other directions, can solve the problems of large working platform space, automobile wheel hub damage, automobile wheel hub accumulation and other problems, and achieve the effect of high work efficiency, low labor intensity and high packaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

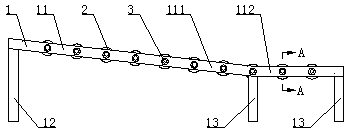

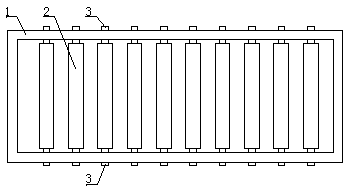

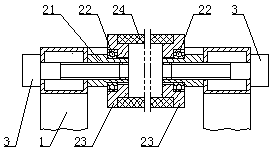

[0009] see Figure 1 to Figure 3 The conveying device for the automobile hub packaging line of the present invention includes a frame 1 and several roller assemblies 2, the frame 1 includes a frame 11, a long machine foot 12 and a short machine foot 13, and the frame 11 includes a left section inclined frame 111 and The right section of the horizontal frame 112, the drum assembly 2 includes a plastic round pipe 24, two bushings 21, two bearings 22 and two plugs 23, and the two bushings 21 are symmetrically installed on both sides of the plastic round pipe 24 , the two bearings 22 are symmetrically installed in the holes of the shaft sleeves 21 on the two sides of the plastic round tube 24, and the two plugs 23 are symmetrically installed in the holes of the bearings 22 on the two sides of the plastic round tube 24. The two ends of each drum assembly 2 all adopt screws 3 to be contained in the frame 11 of the frame 1. The left slanting frame 111 is gradually lowered from left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com