A carton buckle feeding device for a carton handle threading machine

A carton handle and feeding device technology, applied in paper/cardboard containers, packaging, papermaking, etc., can solve problems such as low production efficiency, difficulty in ensuring product quality, and damage to packaging boxes and boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

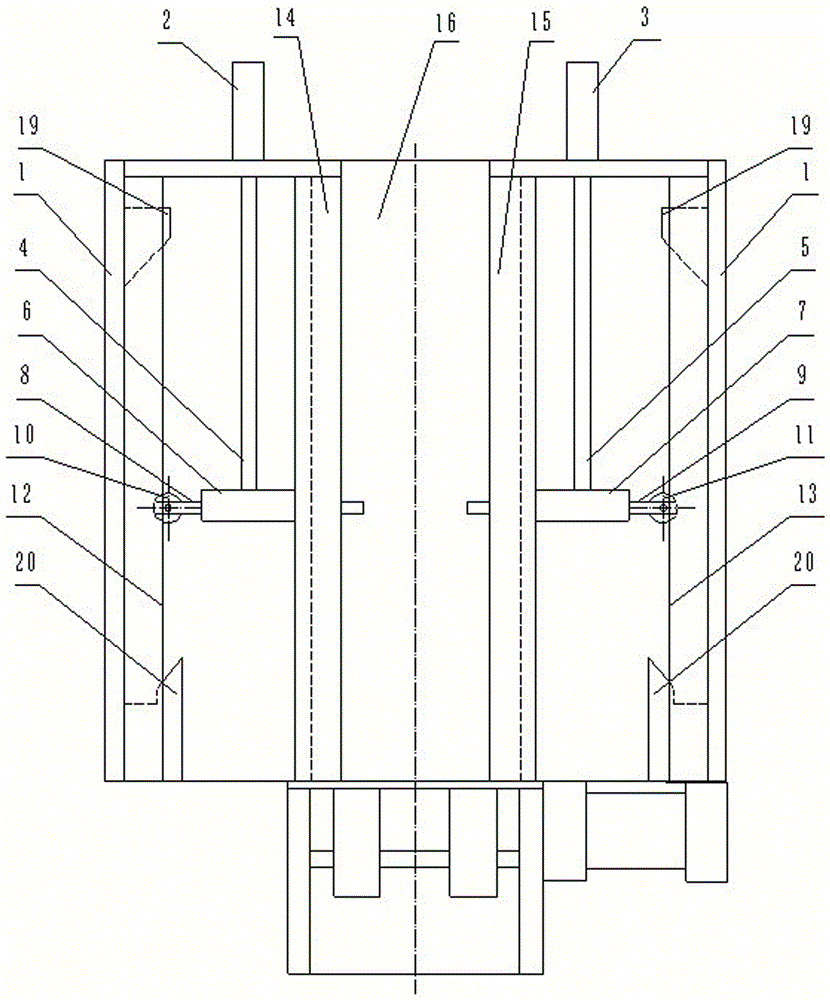

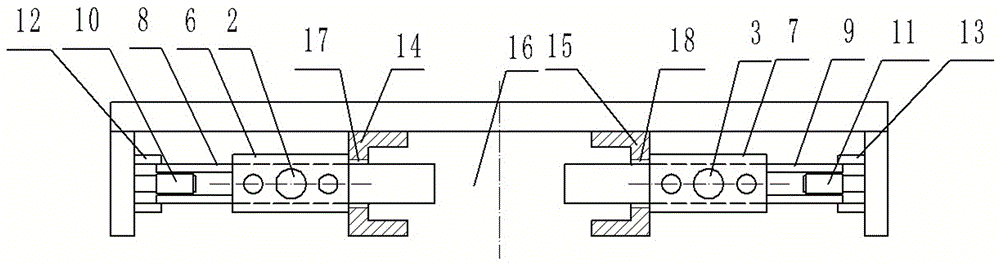

[0009] The carton buckle feeding device of the carton handle buckle threading machine of the present invention will be further described in detail with reference to the accompanying drawings and embodiments. The accompanying drawings constituting this application are used to provide a further understanding of the present invention, and the schematic embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute improper limitations to the present invention.

[0010] Such as figure 1 , figure 2 It can be seen that the carton buckle feeding device of a carton handle buckle threading machine in this embodiment includes a frame 1, which is arranged on the frame 1 and transports the carton buckle from the upper entrance of the buckle trough 16 to the buckle The carton buckle feeding unit of the lower end outlet of the chute 16. The carton buckle feed unit is composed of a left buckle feed cylinder 2, a right buckle fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com