Emergency braking device of elevator

An emergency braking and elevator technology, which is applied in transportation, packaging, elevators, etc., can solve the problems of increasing the deflection of elastic bodies, increasing the size of elastic bodies, and large-scale emergency braking devices, so as to prevent large-scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

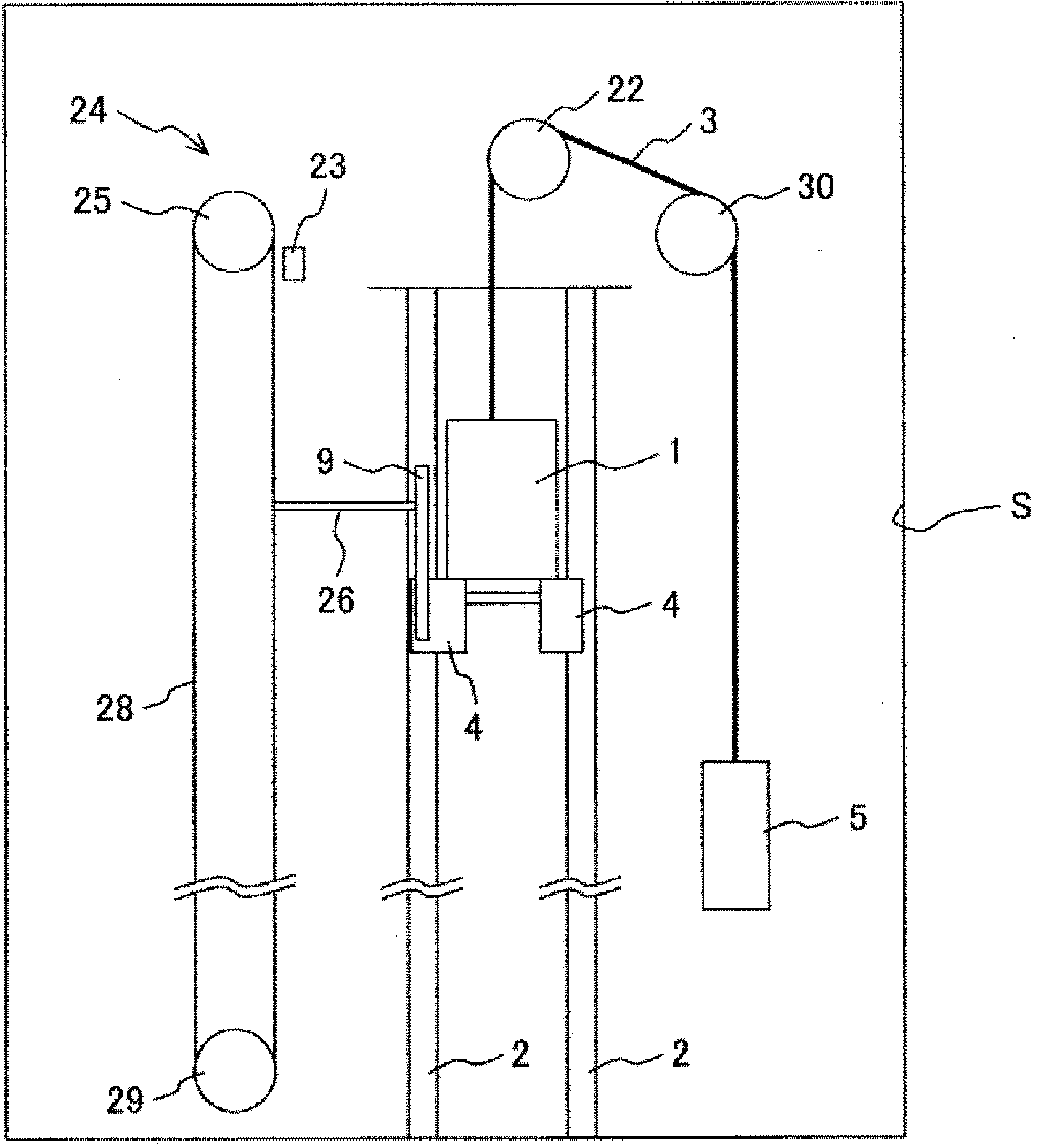

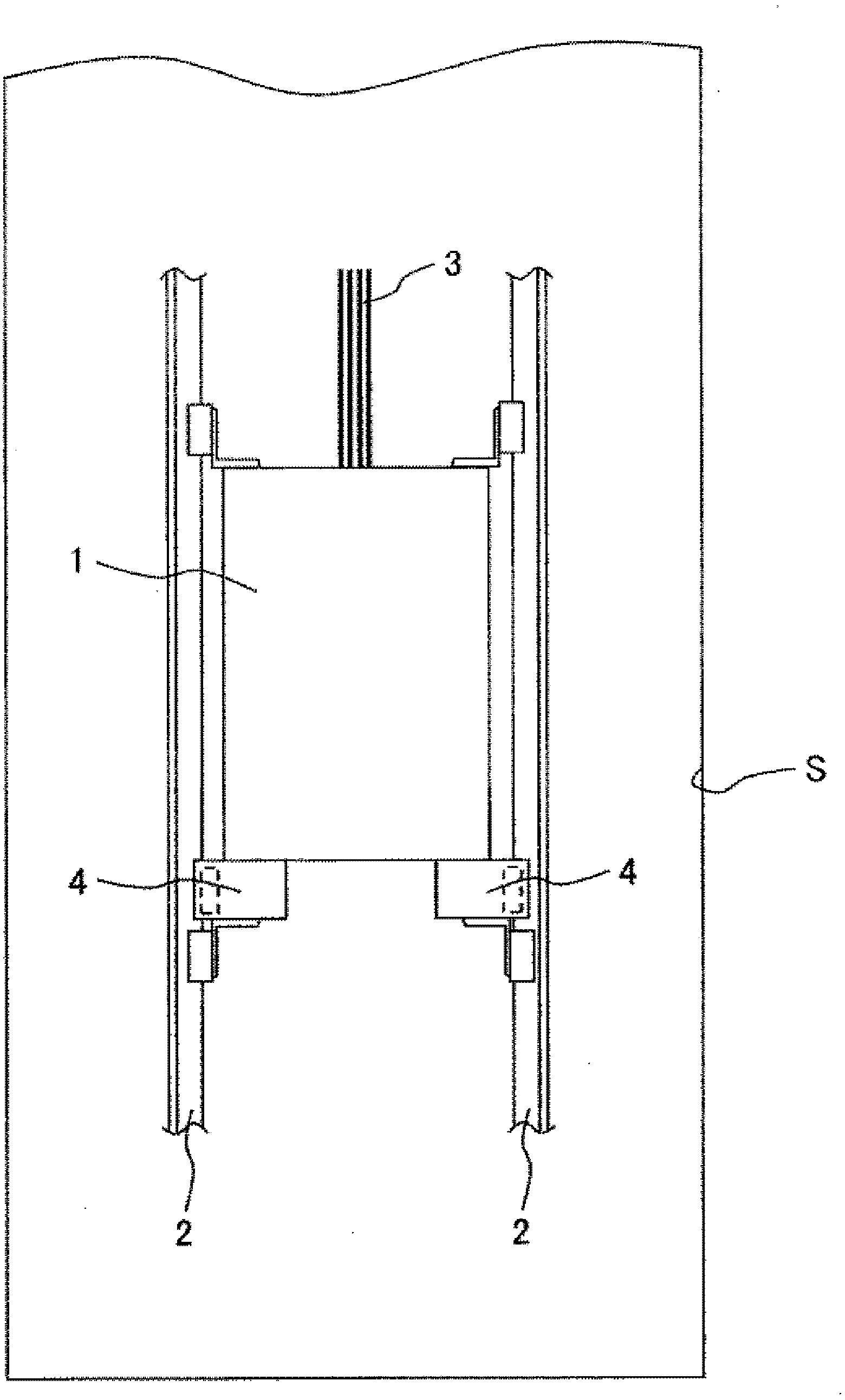

[0057] Below, refer to Figure 3 to Figure 5 The emergency braking device of the first embodiment will be described.

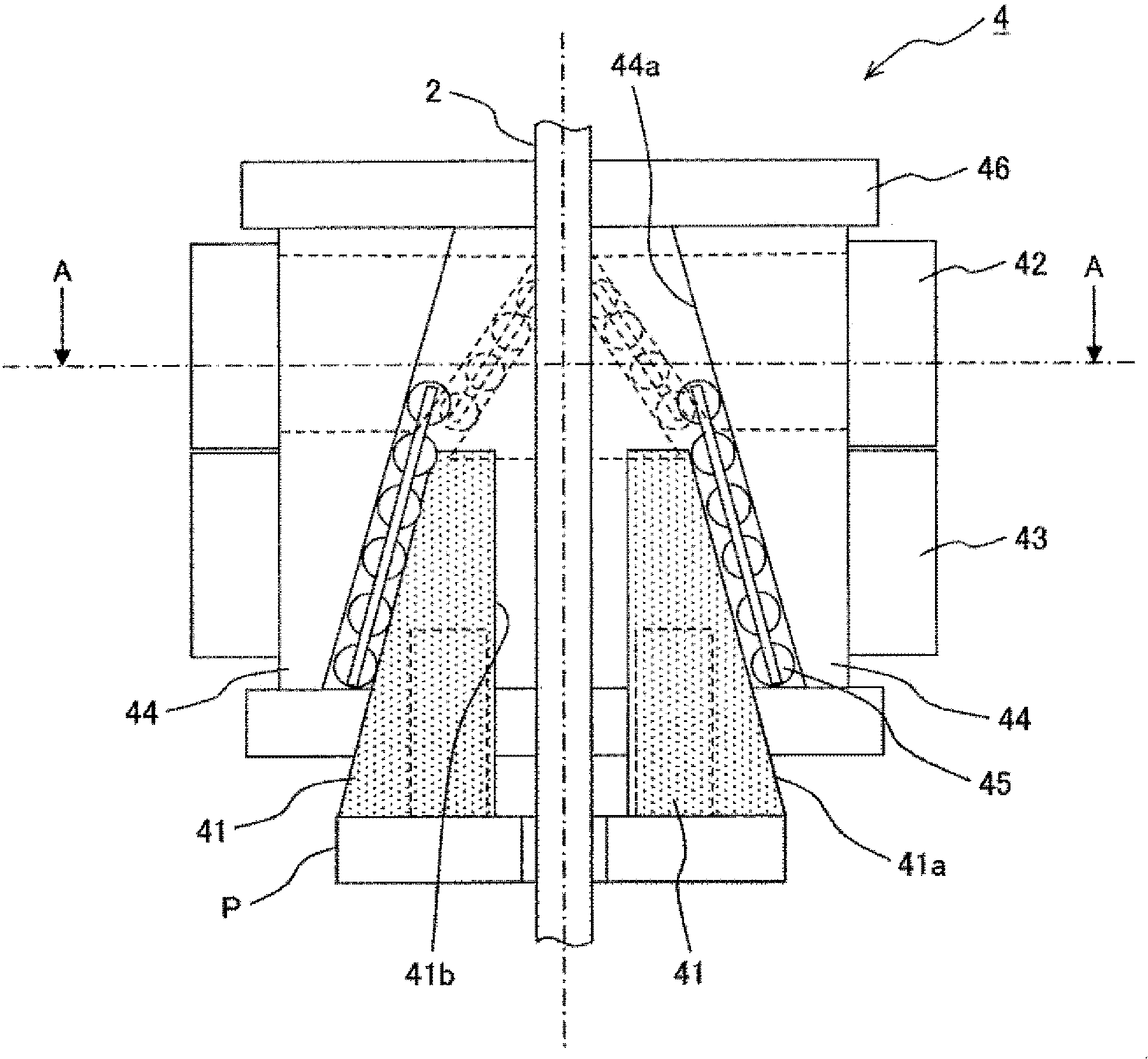

[0058] image 3 It is a schematic diagram showing the emergency braking device for an elevator according to the first embodiment of the present invention. The emergency braking device 4 has: brake shoes 41, which are arranged in pairs on the left and right, and are used to clamp the guide rail 2; When the predetermined speed limit is reached, the brake shoe 41 is brought into sliding contact with the guide rail 2 . In addition, the emergency braking device 4 has an inclined body 44 for guiding the brake shoe 41, a roller 45 provided between the brake shoe 41 and the inclined body 44, and an emergency braking device main body 46 for supporting these components. .

[0059] The brake shoe 41 has a friction surface 41b in contact with the guide rail 2 and an inclined surface 41a provided on the opposite side of the friction surface 41b. The inclined body 44 h...

no. 2 example

[0073] Figure 11 It is a schematic diagram which shows the emergency brake apparatus of the elevator which concerns on the 2nd Example of this invention. In the first embodiment, the elastic force release device R releases the elastic force of the elastic body by a so-called cam mechanism that moves the inclined body by the brake shoe 41 .

[0074] On the other hand, in the second embodiment, the link mechanism L is employed as the above-mentioned mechanism of the spring force releasing means R. As shown in FIG. After the second slanting body 47 is pressed upward by the locking portion 41c of the brake shoe 41, the third slanting body 48 is opened to the left and right by the link structure L, and the elastic body is opened by opening the third slanting body 48. 42 is opened, thereby releasing the pressure on the brake shoe 41. For the sake of convenience, the second inclined body 47 and the third inclined body 48 have been described using the form of the first embodiment, ...

no. 3 example

[0076] Figure 12A and Figure 12B It is a schematic diagram which shows the emergency brake apparatus of the elevator which concerns on the 3rd Example of this invention. In the present invention, the pressing force applied to the brake shoe by the divided elastic body as a whole is set so as to provide an appropriate braking force to the emergency braking device under the dynamic friction coefficient acting normally. At this time, the elastic force of the elastic body to be released is determined according to conditions such as braking speed and dynamic friction coefficient, so the division of the elastic body is as follows: Figure 12A and Figure 12B Shown can be divided according to any ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com