Preparation method of m-type calcium permanent magnet ferrite

A technology of permanent magnet ferrite and ferrite, applied in the direction of magnetism of inorganic materials, can solve the problems of long secondary ball milling time, limited magnetic performance, wide particle size distribution, etc., and achieve the effect of ensuring comprehensive magnetic performance and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

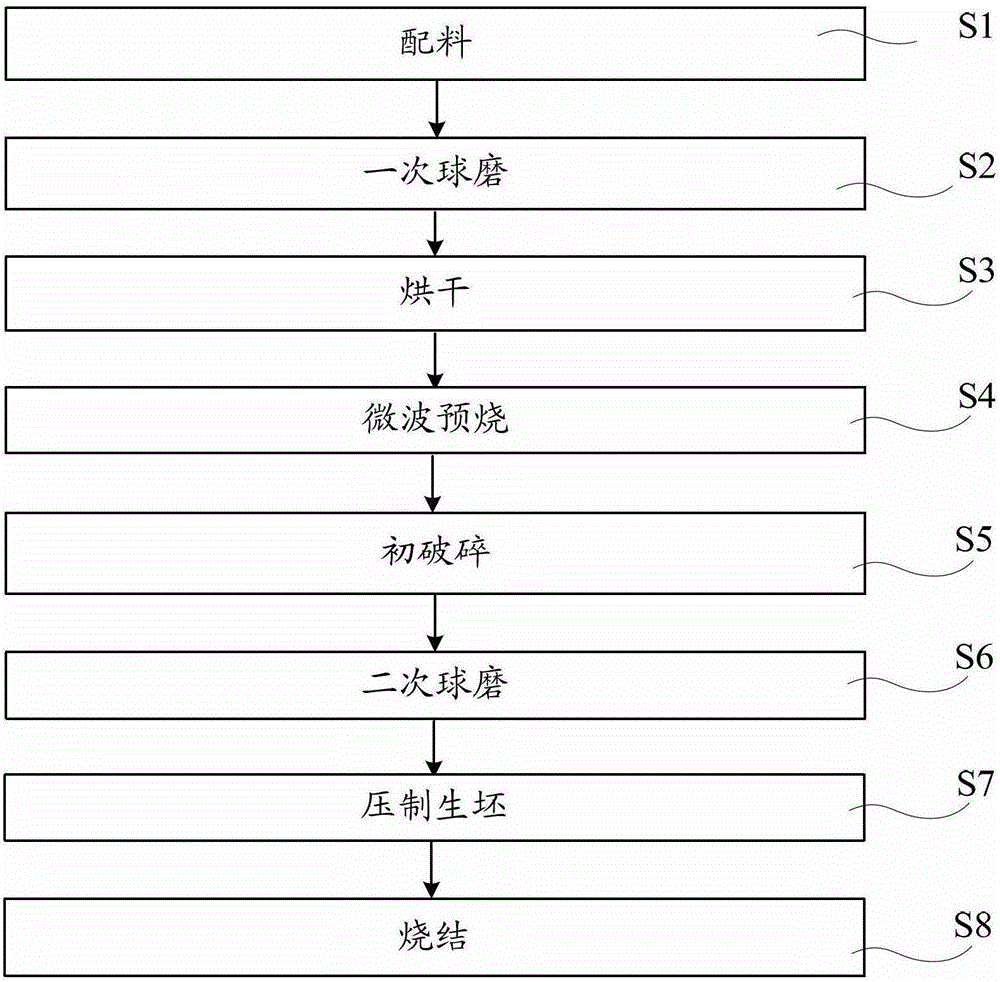

[0040] Please refer to figure 1 , figure 1 The flow chart of the preparation method of the M-type calcium permanent magnet ferrite that the embodiment of the present invention provides, such as figure 1 Shown, the preparation method of the M type calcium permanent magnet ferrite provided by the invention comprises the steps:

[0041] S1. Ingredients: according to chemical structural formula A 1-x-y Ca x R y Fe 2n-z m z o 19 The composition requires the preparation of main material powder; add additive H by weight percentage 3 BO 3 , SiO 2 , CaCO 3 , La 2 o 3 、Co 3 o 4 and SrCO 3 , each component accounts for A 1-x-y Ca x R y Fe 2n-z m z o 19 The weight percentage is 0≤H 3 BO 3 ≤0.5%, 0≤SiO 2 ≤1.0%, 0.1%≤CaCO 3 ≤1.2%, 0≤La 2 o 3 ≤1.0%, 0≤Co 3 o 4 ≤1.0%, 0≤SrCO 3 ≤0.8%; and mixing and stirring the main material powder and the additive into a material powder;

[0042] S2, a ball mill: Put the powder into the ball mill for grinding, add steel balls w...

Embodiment 1

[0057] In this embodiment, the main phase of the M-type calcium permanent magnet ferrite is: Sr 0.72 Ca 0.05 La 0.23 Fe 11.21 co 0.19 o 19 , its preparation method is:

[0058] The batching process selects the raw materials of main ingredients as follows:

[0059] Fe 2 o 3 powder (of which Fe 2 o 3 The purity of the powder ≥ 99.3wt%, the original average particle size of the particles: 0.75um) 84.48wt%;

[0060] SrCO 3 Powder (purity ≥ 99%, original average particle size of particles: 1.0um) 10.06wt%;

[0061] La 2 o 3 Powder (purity ≥ 99%, original average particle size of particles: 2.0um) 3.55wt%;

[0062] co 3 o 4 Powder (purity ≥ 99.3%, original average particle size of particles: 0.8um) 1.44wt%;

[0063] CaCO 3Powder (purity ≥ 99.9%, original average particle size of particles: 2um) 0.47wt%;

[0064] The additives selected in the batching process are as follows:

[0065] h 3 BO 3 , SiO 2 , CaCO 3 , La 2 o 3 、Co 3 o 4 and SrCO 3 , each compone...

Embodiment 2

[0086] The raw material selection is the same as in Example 1, except that microwave pre-firing is divided into primary pre-firing and secondary pre-firing. Among them, the primary pre-firing is microwave pre-firing, and the second pre-firing uses a traditional muffle furnace for pre-firing.

[0087] The pre-firing temperature of the primary pre-firing is 1150°C, and the holding time is 30 minutes. The temperature of the secondary pre-burning is 1150°C, and the holding time is 90 minutes; the main phase formula with ferrite can be expressed as: Sr 0.72 Ca 0.05 La 0.23 Fe 11.21 co 0.19 o 19 .

[0088] Subsequent process is substantially the same as Example 1;

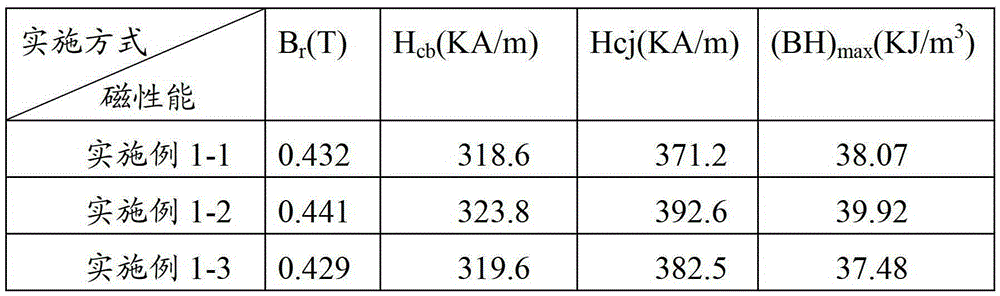

[0089] Randomly extract three samples in the samples of a plurality of sintered permanent magnet ferrites obtained in embodiment 2 and carry out upper and lower surface grinding, measure its residual magnetic induction (B r ), coercive force (H cb ), internal coercive force (Hcj), maximum energy product (BH) ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com