M-type calcium permanent magnet ferrite and preparation method thereof

A permanent magnet ferrite and ferrite technology, applied in the direction of magnetism of inorganic materials, can solve problems such as different anti-demagnetization ability, difference in grain size, Hk/Hcj and comprehensive magnetic performance decline, so as to improve the final magnetic performance , reduce the sintering temperature, and ensure the effect of comprehensive magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

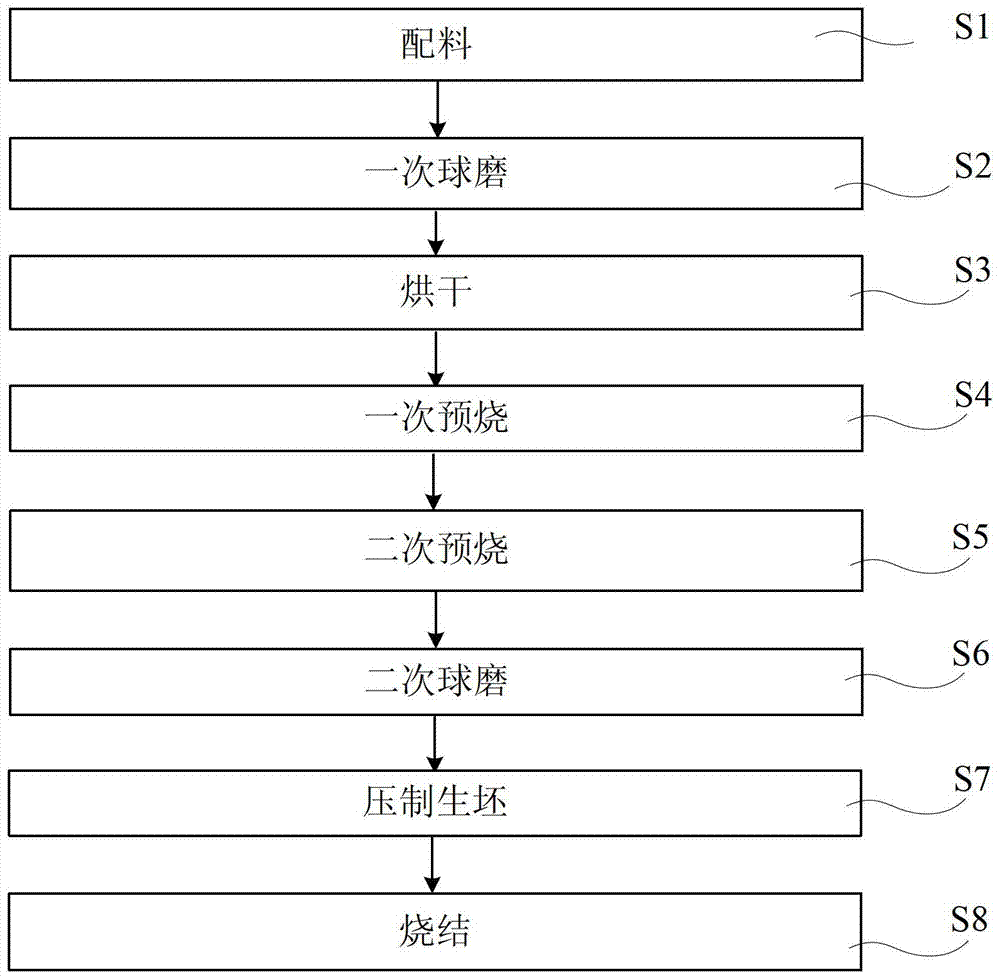

[0068] Please refer to figure 1 , figure 1 The flow chart of the preparation method of the M-type calcium permanent magnet ferrite that the embodiment of the present invention provides, such as figure 1 Shown, the preparation method of the M type calcium permanent magnet ferrite provided by the invention comprises the steps:

[0069] S1. Ingredients: according to chemical structural formula A 1-x-y Ca x R y Fe 2n-z m z o 19 The composition requires the preparation of main material powder; add additive H by weight percentage 3 BO 3 , SiO 2 , CaCO 3 , La 2 o 3 、Co 3 o 4 and SrCO 3 , each component accounts for A 1-x-y Ca x R y Fe 2n-z m z o 19 The weight percentage is 0≤H 3 BO 3 ≤0.5%, 0≤SiO 2 ≤1.0%, 0.1%≤CaCO 3 ≤1.2%, 0≤La 2 o 3 ≤1.0%, 0≤Co 3 o 4 ≤1.0%, 0≤SrCO 3 ≤0.8%; and mixing and stirring the main material powder and the additive into a material powder;

[0070] S2, a ball mill: Put the powder into the ball mill for grinding, add steel balls w...

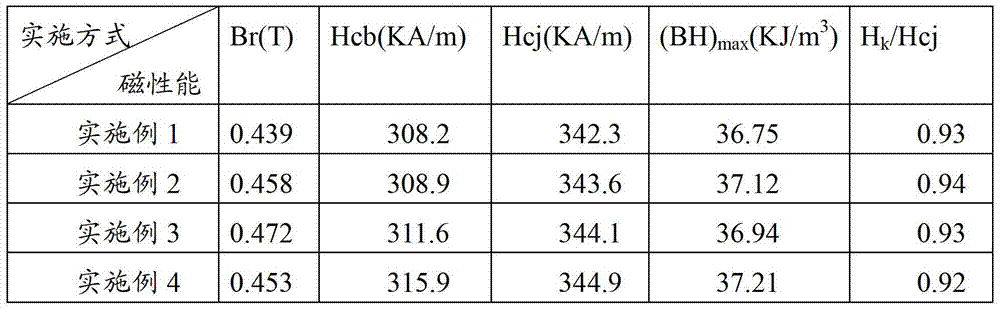

Embodiment 1

[0082] The M-type calcium permanent magnet ferrite provided by this embodiment includes the hexagonal ferrite main phase of elements such as A, R, Ca, Fe and M, and has the molecular formula of the following characteristics: A 1-x-y Ca x R y Fe 2n-z m z o 19 , where A is Sr, R is a combination of Pr and La, M is a combination of Ni and Co, the value of x is 0.05, y is 0.25, z is 0.13, and n is 5.80. That is, the characteristic molecular formula of the M-type calcium permanent magnet ferrite provided by the present embodiment is Sr 0.7 Ca 0.05 (La 0.20 PR 0.05 )Fe 11.47 (Ni 0.03 co 0.10 )O 19 .

Embodiment 2

[0084] The M-type calcium permanent magnet ferrite provided by this embodiment includes the hexagonal ferrite main phase of elements such as A, R, Ca, Fe and M, and has the molecular formula of the following characteristics: A 1-x-y Ca x R y Fe 2n-z m z o 19 , wherein A is Ba, R is a combination of Nd and La, M is a combination of Ni and Co, the value of x is 0.05, y is 0.25, z is 0.13, and n is 5.80. That is, the characteristic molecular formula of the M-type calcium permanent magnet ferrite provided by the present embodiment is Ba 0.7 Ca 0.05 (La 0.21 Nd 0.04 )Fe 11.47 (Ni 0.03 co 0.10 )O 19 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com