Non-oriented electrical steel sheets with improved magnetic property and method for manufacturing the same

A technology of oriented electrical steel sheet and electrical steel sheet, applied in the field of non-oriented electrical steel sheet and its preparation, can solve the problems of increased production cost, unexplained relationship of other components, increased cost, etc., achieve excellent non-oriented, suppress the formation of CuS, The effect of improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Furthermore, to achieve the object, the present invention provides a non-oriented electrical steel sheet with excellent magnetic properties obtained by a preparation method comprising the steps of hot rolling a steel ingot containing 0.004 wt. % or less of C; 1.0 to 3.5wt.% of Si; 0.02wt.% or less of P; 0.001wt.% or less of S; 0.2 to 2.5wt.% of Al; Less N; 0.004wt.% or less Ti; Mn, wherein the amount of Mn is represented by the above formula (1); the balance is iron; and unavoidable impurities; ) within a determined temperature range, the annealing temperature of the hot-rolled steel sheet depends on the amount of S in the continuous annealing stage; the annealed steel sheet is cold-rolled; and the cold-rolled steel sheet is annealed to obtain the steel sheet of the present invention.

[0041] In this case, S precipitates as MnS, and thus leads to fine crystal grains. The amount of S must be small, if possible, due to the ease of formation of such a texture with planes...

Embodiment 1

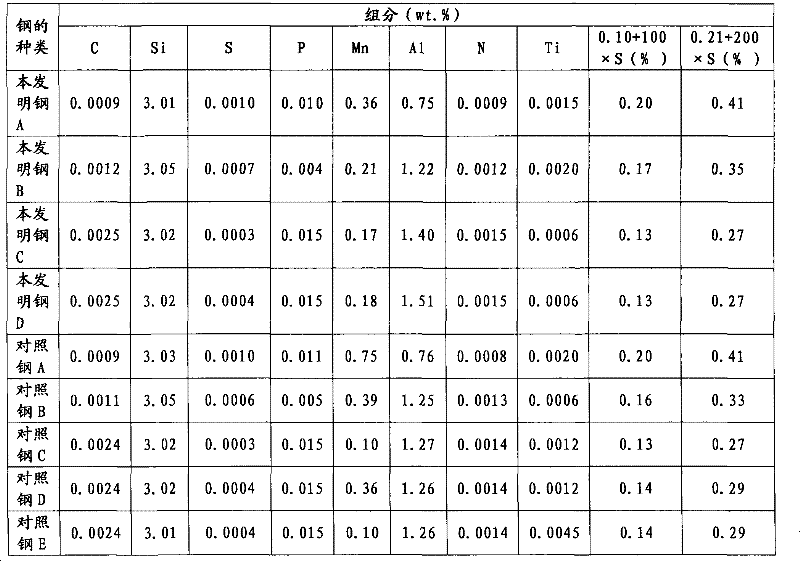

[0091] Steel ingots composed of the compositions in Table 1 were reheated to a temperature of 1100°C, and were subjected to final rolling in a hot rolling process at a temperature of 860°C.

[0092] In this case, the final reduction ratio during finish rolling was 18%. The steel ingot was rolled to a thickness of 1.8 mm and then coiled at a temperature of 650°C.

[0093] The hot-rolled steel sheets were coiled and cooled at ambient conditions, annealed, pickled, and cold-rolled to a thickness of 0.35 mm as shown in Table 2 to form cold-rolled steel sheets. The cold-rolled steel sheet was then annealed at an annealing temperature of 1050°C for 1 minute in an atmosphere of 35% hydrogen and 65% nitrogen.

[0094] After cutting the annealed steel plate, compare the magnetic properties and the texture coefficient obtained according to the Horta formula. The results are given in Table 2.

[0095] [Table 1]

[0096]

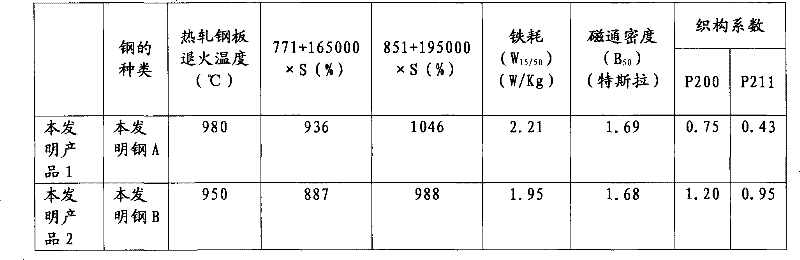

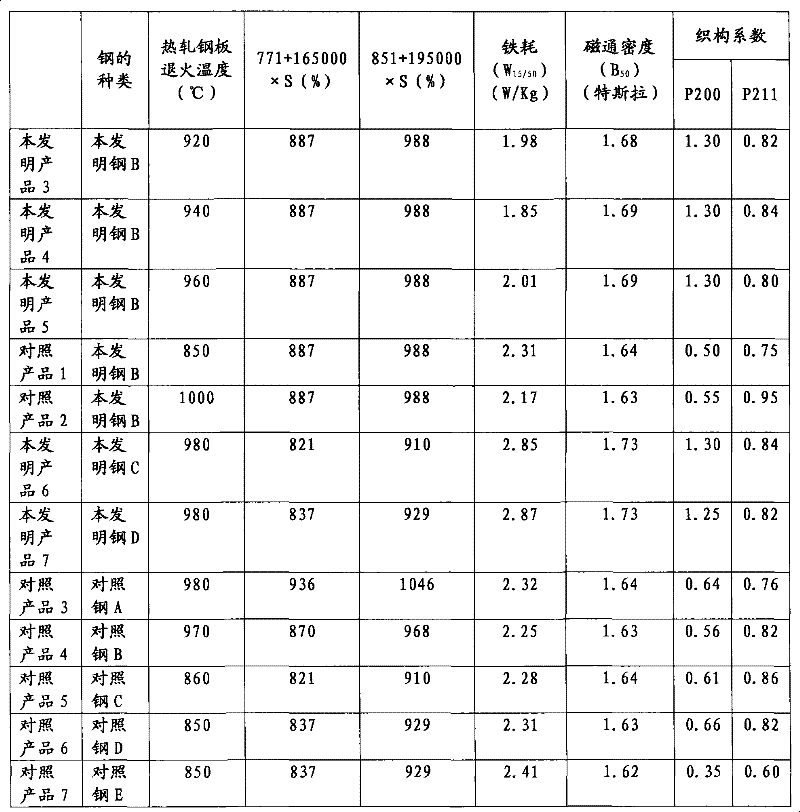

[0097] [Table 2]

[0098]

[0099]

[0100] 1) Iron co...

Embodiment 2

[0107] A steel ingot containing 0.0021wt.%C; 2.52wt.%Si; 0.011wt.%P; 0.0005wt.%S; 0.55wt.%Al; 0.0012wt.%N; Mn, wherein the preferred amount of Mn is 0.15-0.31%; the balance is iron; and unavoidable impurities. The ingot was reheated to a temperature of 1150° C. and then hot rolled. In the hot rolling stage, final rolling in finish rolling was performed at a temperature of 880° C. to have a reduction ratio of 17%, thereby obtaining a hot-rolled steel sheet having a thickness of 2.2 mm.

[0108] This hot-rolled steel sheet was coiled at a temperature of 600° C., and then air-cooled. Next, this hot-rolled steel sheet was continuously annealed at a temperature of 920° C. for 5 minutes, acid-stained, and then cold-rolled to a thickness of 0.5 mm.

[0109] In this case, the suitable temperature range during the annealing of the hot-rolled steel sheet is in the range of 854-979°C, and the annealing process of the cold-rolled steel sheet is performed at a temperature of 1000°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com