Mode-based converter steelmaking automatic control device and application method of automatic control device

An automatic control device and converter steelmaking technology, applied in the manufacture of converters, etc., can solve problems such as unstable operation, errors, and high requirements for operators' professional skills, and achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

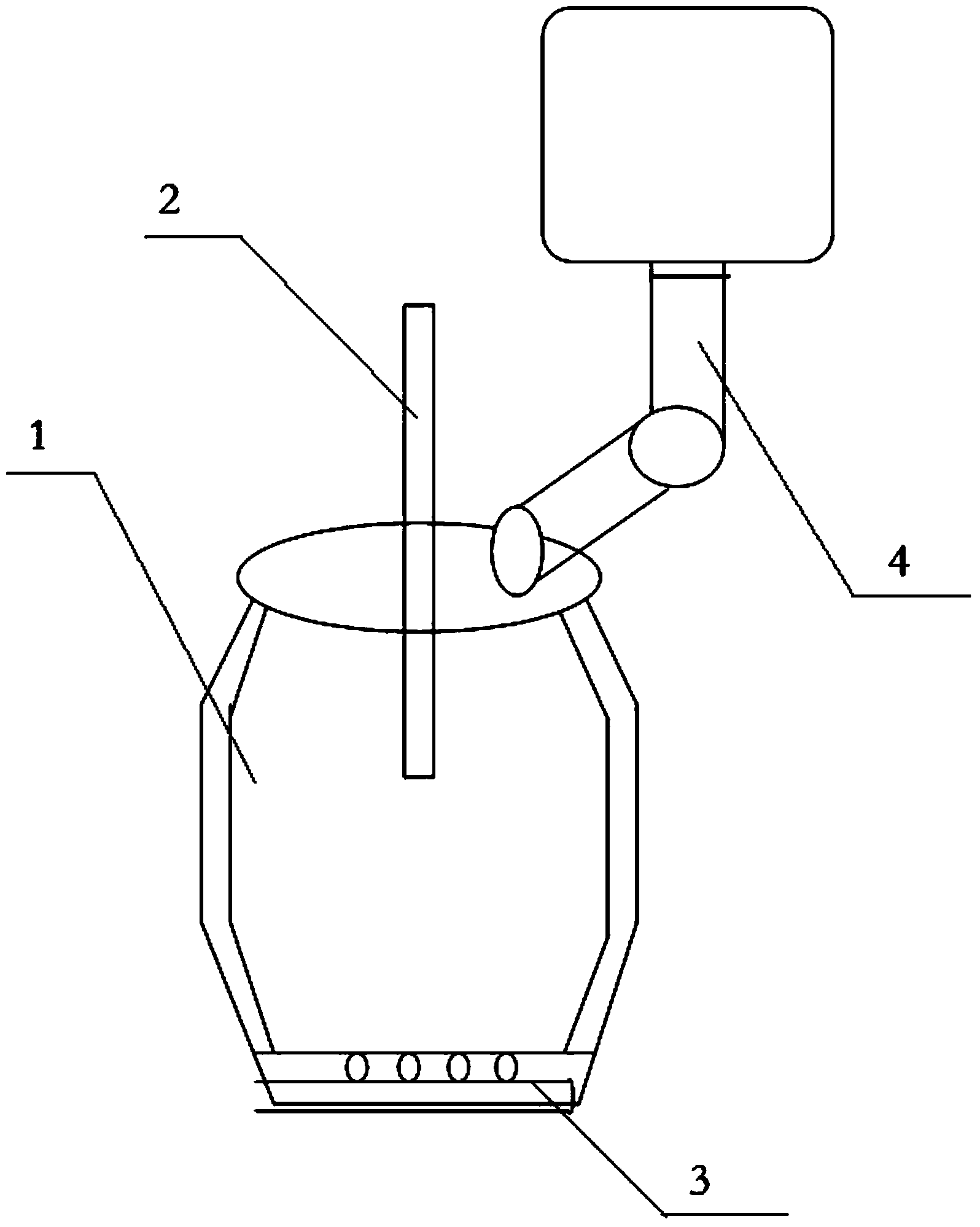

[0020] Example: such as figure 1 The shown model-based automatic control device for converter steelmaking includes a converter body 1 , an oxygen lance 2 and a feeding device 4 arranged above the furnace mouth of the converter body 1 , and a bottom blowing device 3 arranged at the bottom of the converter body 1 . It also includes an oxygen lance control system for controlling the vertical movement of the oxygen lance 2, a bottom blowing control system for controlling the type and flow rate of the gas blown out by the bottom blowing device 3, and a feeding control system for controlling the type and weight of auxiliary raw materials added by the feeding device 4 .

[0021] The method for using the above-mentioned mode-based automatic control device for converter steelmaking includes the following steps:

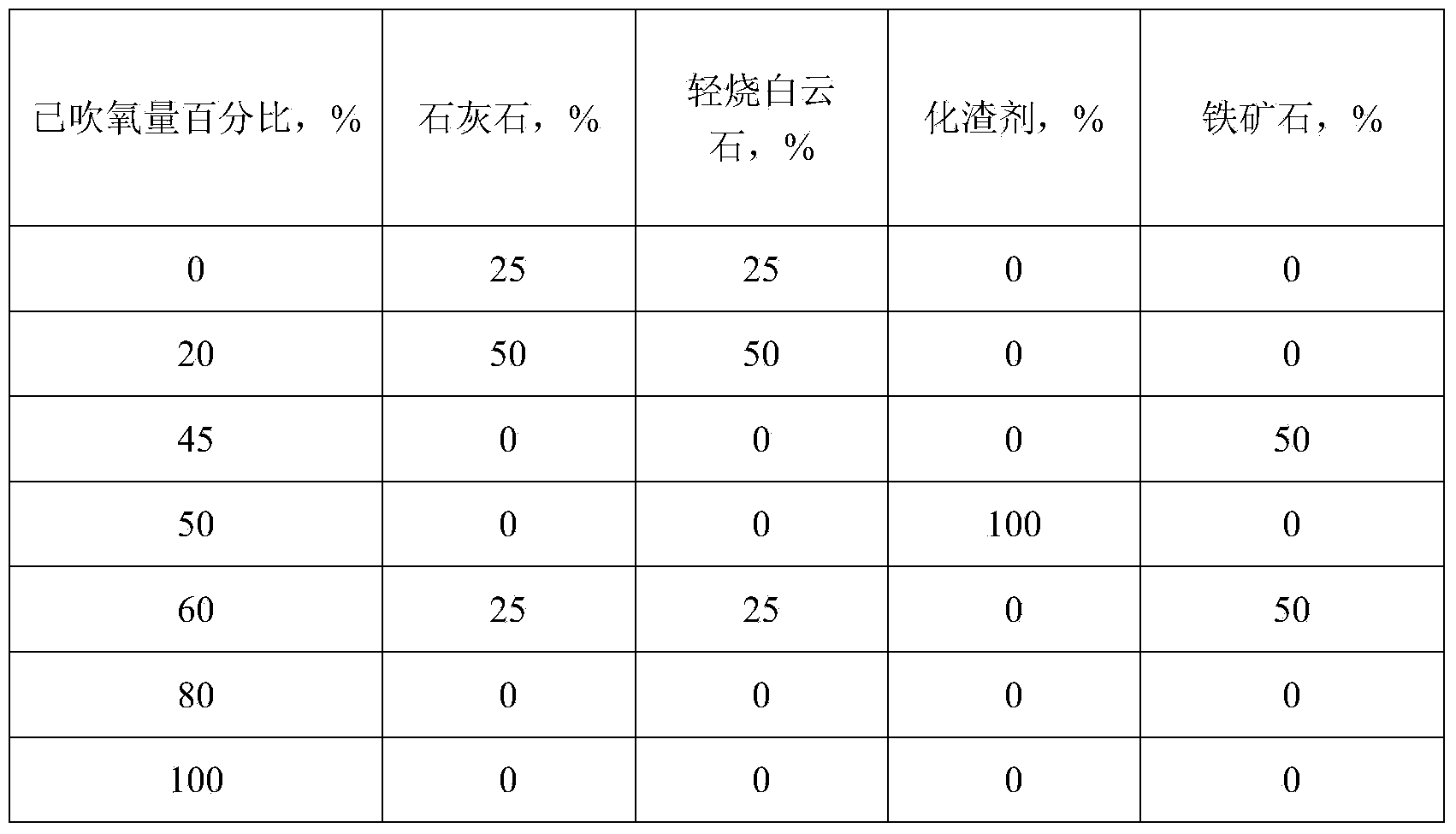

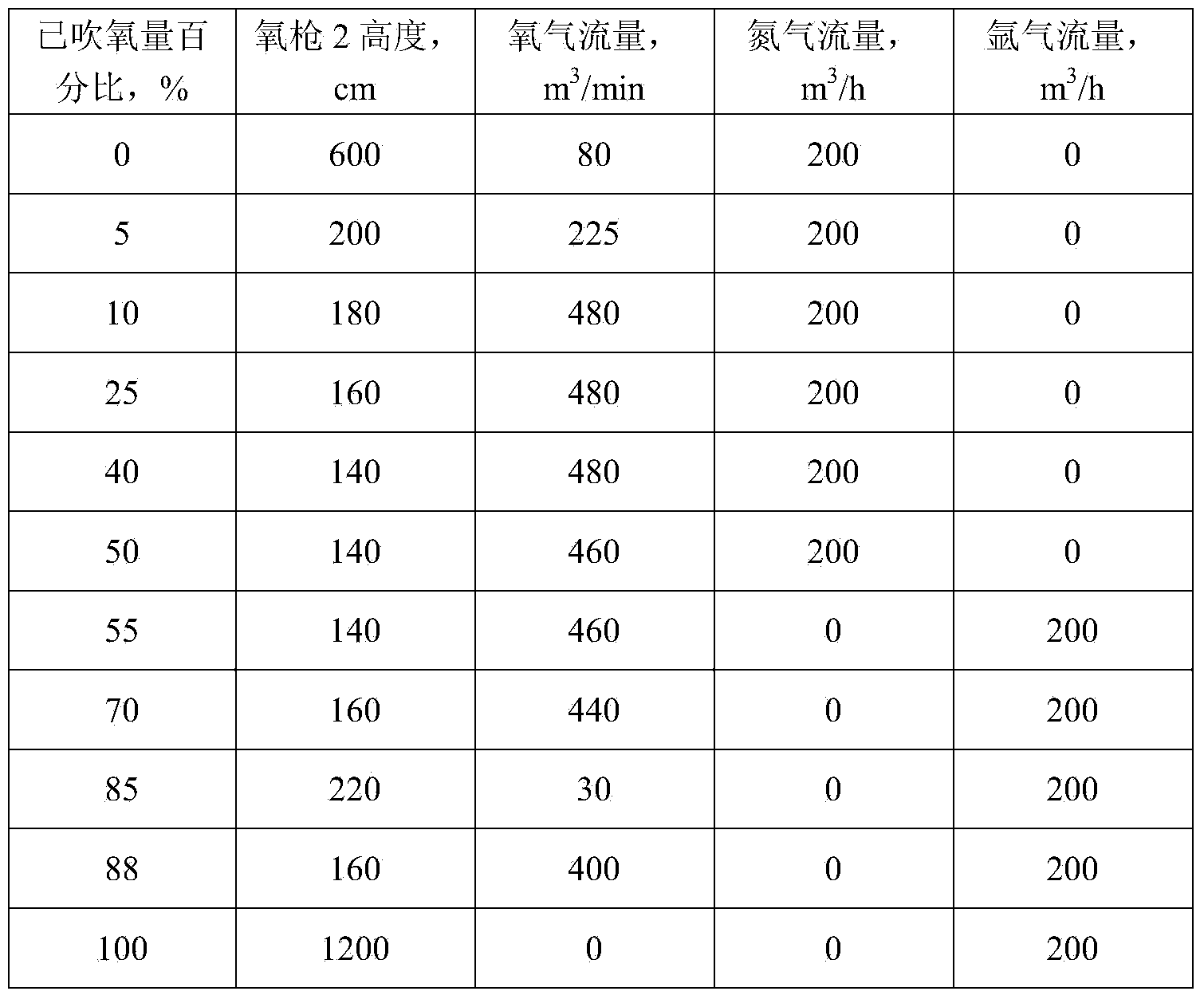

[0022] 1) Add scrap steel and molten iron to the converter to form raw materials and calculate the total amount of oxygen blowing required in the steelmaking process and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com