A Heat Treatment Process for 3m Bearing Ring of Shield Machine

A bearing ring, shield machine technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as unreported heat treatment process research, and achieve the effect of satisfying hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A steel for bearing rings after alloying design has the following chemical composition in mass percentage: 0.39%C, 0.26%Si, 0.64%Mn, 0.76%Cr, 1.49%Ni, 0.06%Cu, 0.19%Mo, 0.014%P, 0.002%S, the balance is Fe.

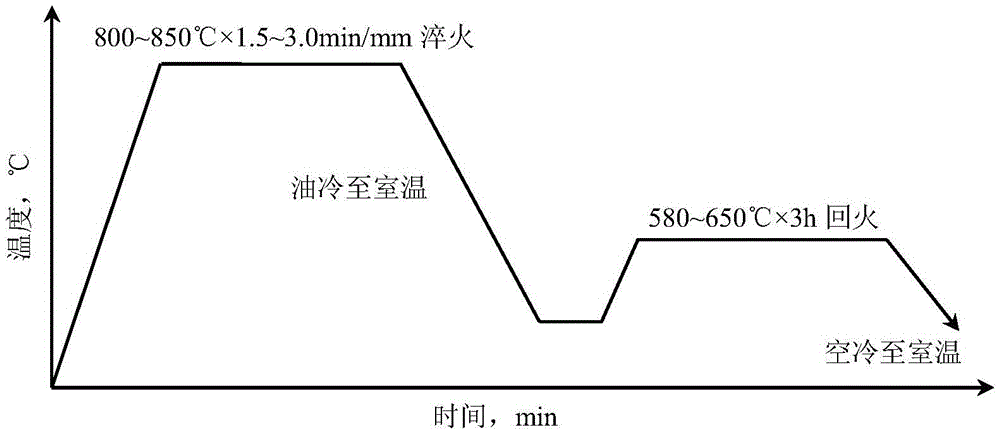

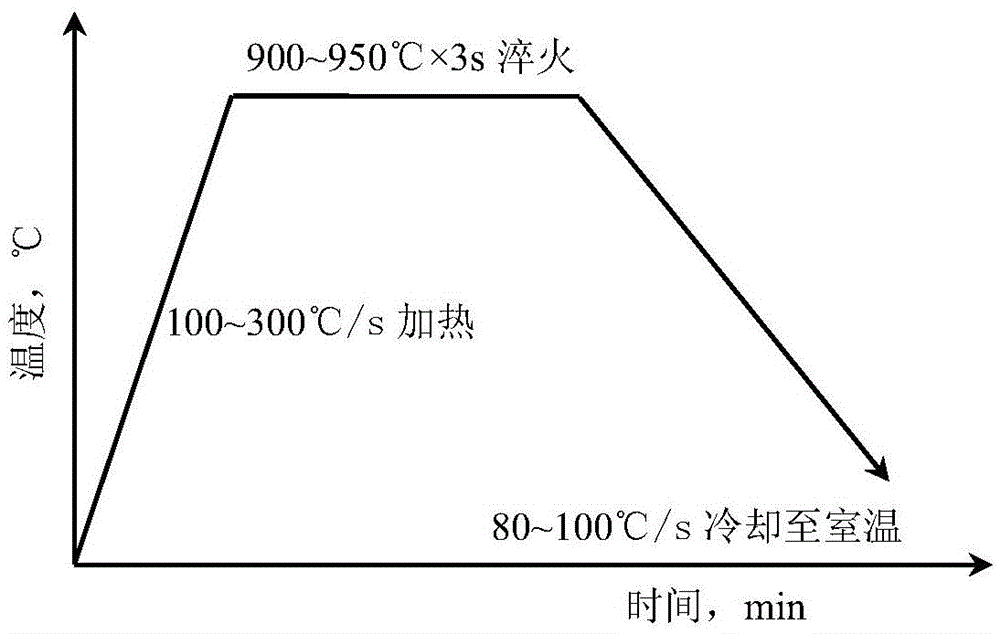

[0024] The heat treatment process parameters adopted in the embodiment are shown in Table 1. The impact toughness and hardness of the quenched and tempered state after heat treatment and the hardness after surface induction hardening are shown in Table 2. It can be seen that the impact toughness AK of the matrix at -20°C v The average value is 115J, the average hardness of the matrix is 293HB, and the average surface quenching hardness is 57.9HRC. It can be seen that after the composition design and heat treatment process, the matrix toughness, hardness and surface induction hardening hardness can meet the performance requirements of the steel for the 3m bearing ring of the shield machine.

[0025] The heat treatment process parameter that the embodiment of tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com