Building block and reinforced concrete laminated wall and construction method thereof

A technology of reinforced concrete and blocks, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of supply and demand (complex procedures, long construction period, time-consuming, etc.), and achieve the effect of simplifying the construction process, reducing construction costs and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

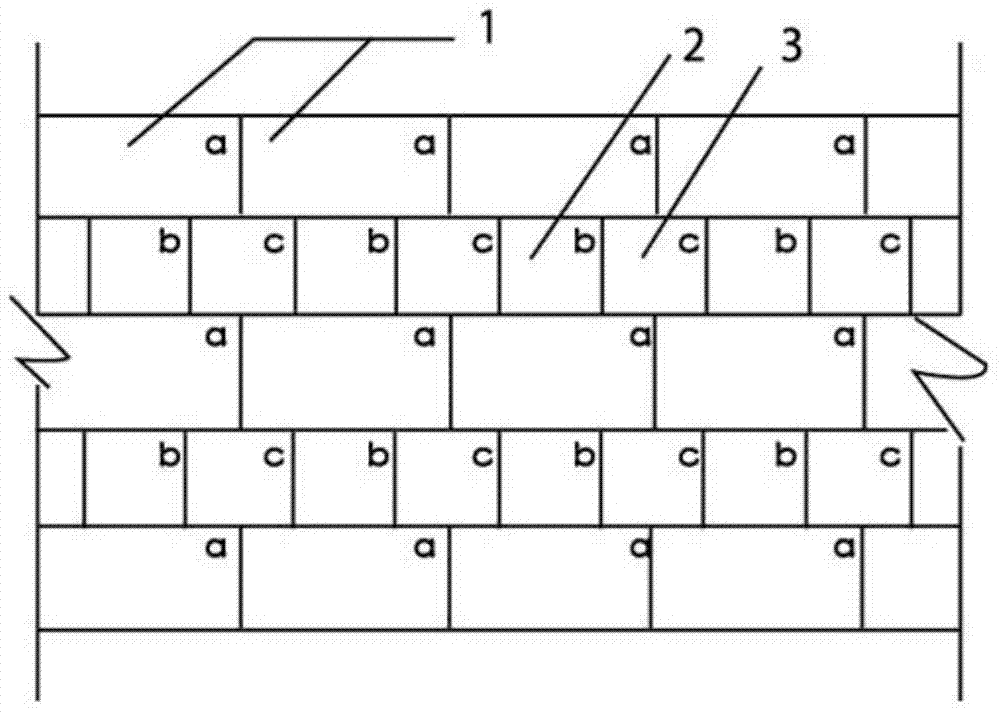

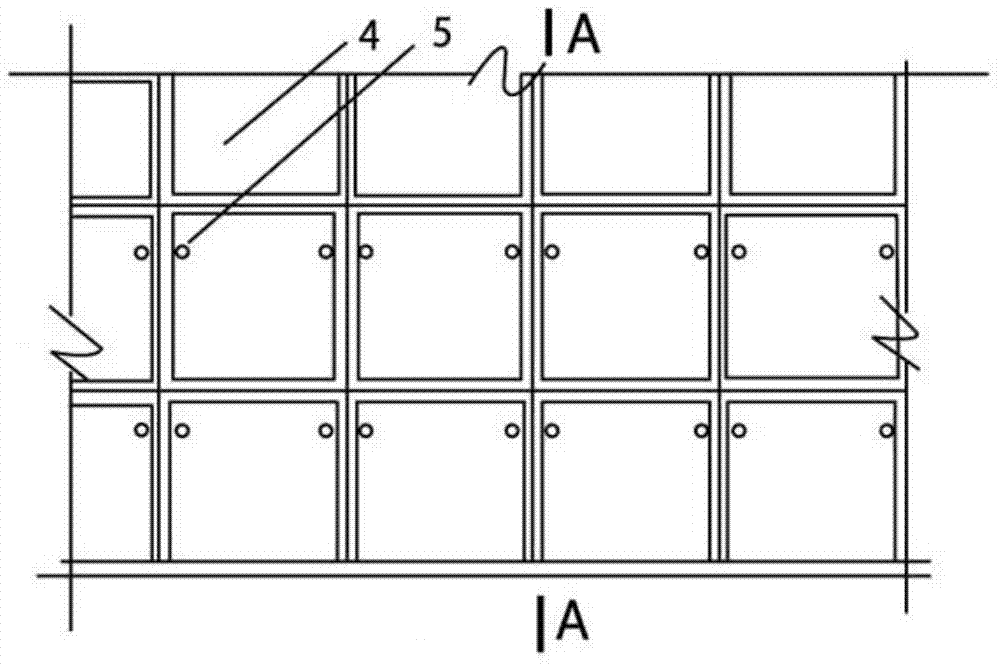

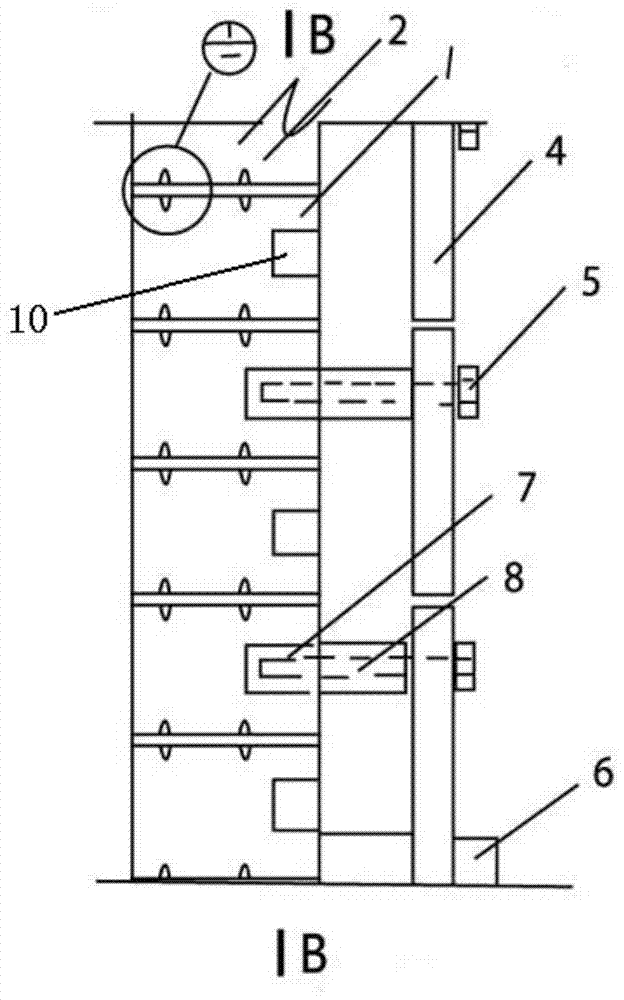

[0028] see figure 1 , 2 , 3, 4 shown. Block and reinforced concrete laminated wall, including block 1, 2, 3, block fixing connector (bricklaying positioning card 9) and reinforced concrete pouring layer; described block is divided into three types, the first It is a type, with one or two annular grooves on the surrounding sides, a cross-shaped groove on the back, and the annular groove and the cross-shaped groove do not overlap on the cross-section, and the front is a flat structure; the second type is b type, with one or two annular grooves on the sides, a glyph groove on the back and the two annular grooves do not coincide with the inline groove on the cross section, and a flat structure on the front; the third type is c-type , there are one or two annular grooves around the sides, the front is flat, and the back is embedded with an inverted trumpet-shaped embedded block 7 structure, and there are fixing bolts 5 fixing holes on the embedded block 7; the block is placed fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com