Force arm actuated power generating device

A technology of power generation device and lever arm, which is applied in the field of lever arm actuated power generation device, can solve problems such as the inability to maximize energy conversion, and achieve the effects of short investment recovery period, low cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

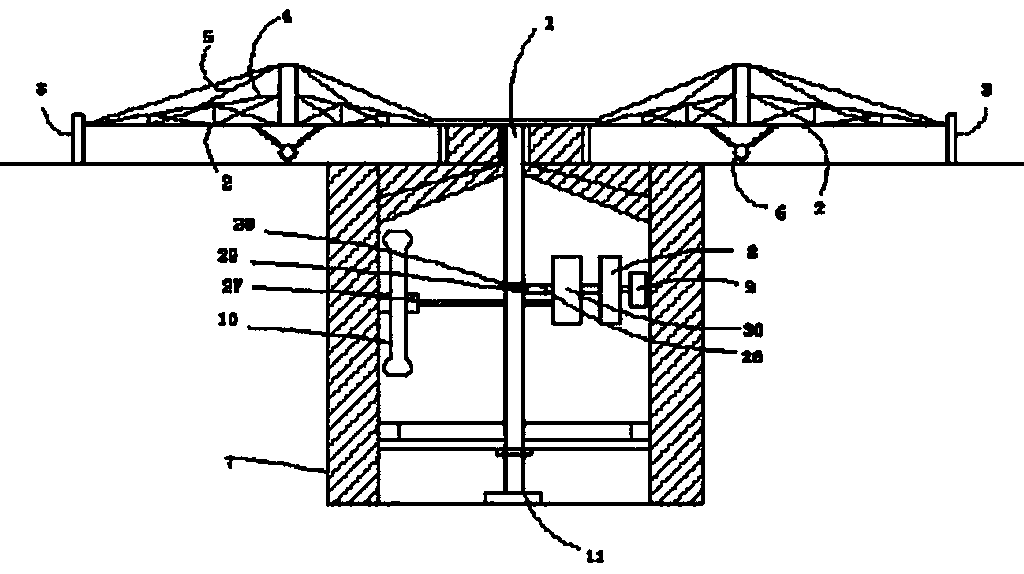

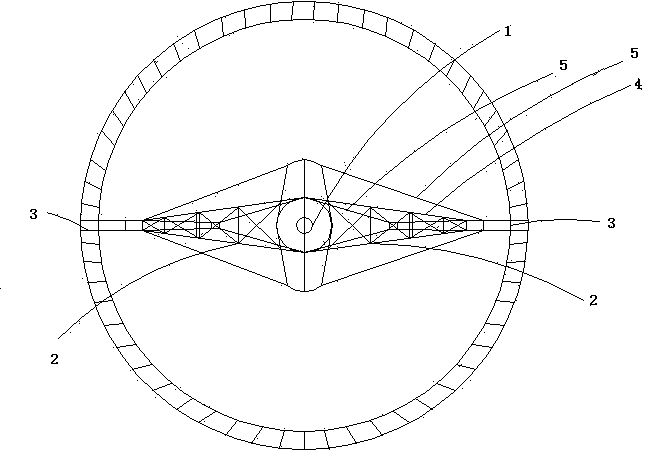

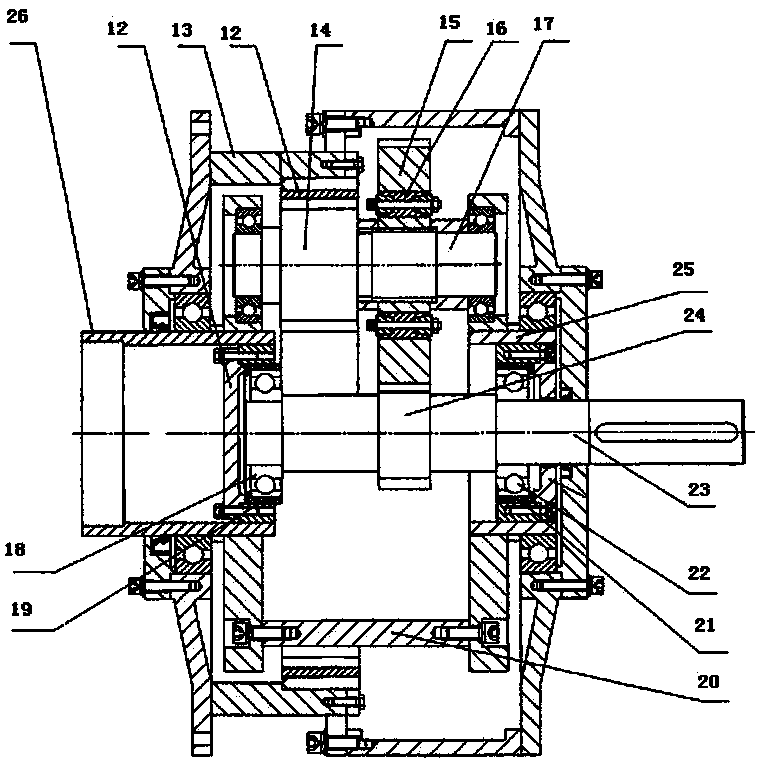

[0011] Such as Figure 1-3 As shown, the force arm actuated power generation device includes a first transmission shaft 1, a force arm 2, a driving source 3, a steel frame 4, a steel cable 5, a pulley 6, a support frame 7, a power generator Speed box 8, a generator 9, a flywheel 10, a base 11, an inner ring gear 12, a speed-increasing box body 13, a small planetary gear 14, a large planetary gear 15, a set of body 16, a planet Gear shaft 17, a front bearing 18, a front elastic sleeve 19, a planet carrier 20, a rear elastic sleeve 21, a rear bearing 22, a central shaft 23, a sun gear 24, a rear bearing support sleeve 25, a first Two transmission shafts 26, a flywheel transmission shaft 27, a longitudinal bevel gear 28, a transverse bevel gear 29, a flywheel speed increasing box 30.

[0012] combine Figure 1-3 As shown, in this embodiment, the drive source 3 is detachably connected to the arm 2 in the tram mode to provide initial power for the arm 2, but the drive source 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com