A kind of wooden furniture and its assembly method

An assembly method and furniture technology, which is applied in the direction of furniture connection, connection components, mechanical equipment, etc., can solve the problem of difficult to eliminate rough seams and sharp corners at the junction of end faces, the color of the solid wood frame and the inner panel are consistent, and the consumption of natural high-quality wood and other problems to achieve the effect of saving high-quality wood, avoiding easy bursting, rounded corners and beautiful closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by way of example in conjunction with accompanying drawing the present invention will be further described:

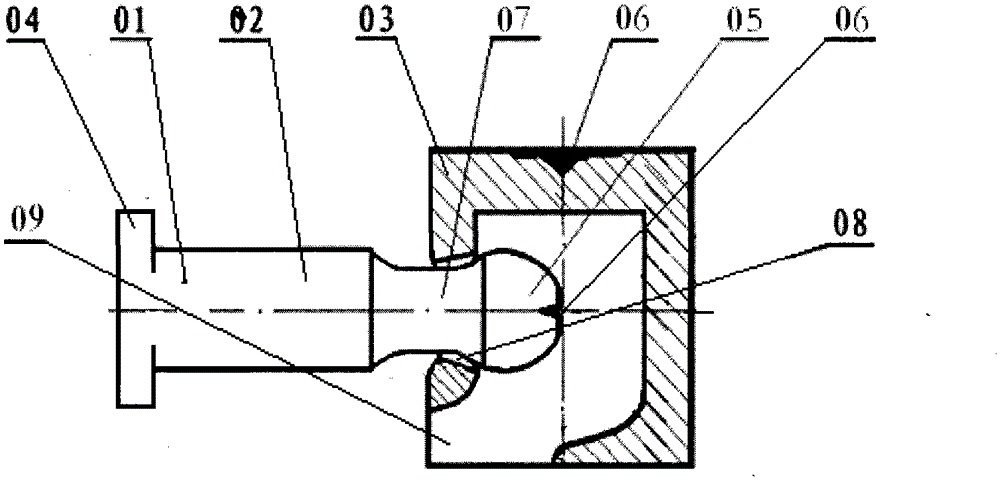

[0018] figure 1 It is a structural schematic diagram of an embodiment of the eccentric locking assembly of the present invention. (01) in the figure is an eccentric locking assembly, which is elongated in appearance and is composed of a columnar connecting rod (02) and a cylindrical eccentric member (03). One end of the connecting rod (02) is made of Or "T"-shaped or "Γ"-shaped or dovetail-shaped or screw-shaped buckle head (04), the other end is shaped on a spherical head (05) with a spherical crown, and the top of the spherical head (05) is shaped on a concave "ten". "Word screwdriver groove (06), is shaped on concave annular groove (07) at the connecting position of spherical head (05) and connecting rod (02). The upper end surface of the eccentric member (03) is formed with a concave "ten" screwdriver groove (06), and the lower end surface is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com