Electric ceramic stove core

A technology of electric ceramic stove and movement, applied in the field of electric ceramic stove, can solve the problems of large thermal radiation influence of circuit board, easy distortion of reset spring, easy shaking of heating plate, etc., and achieves compact structure, good elastic reset performance, and improved heat dissipation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

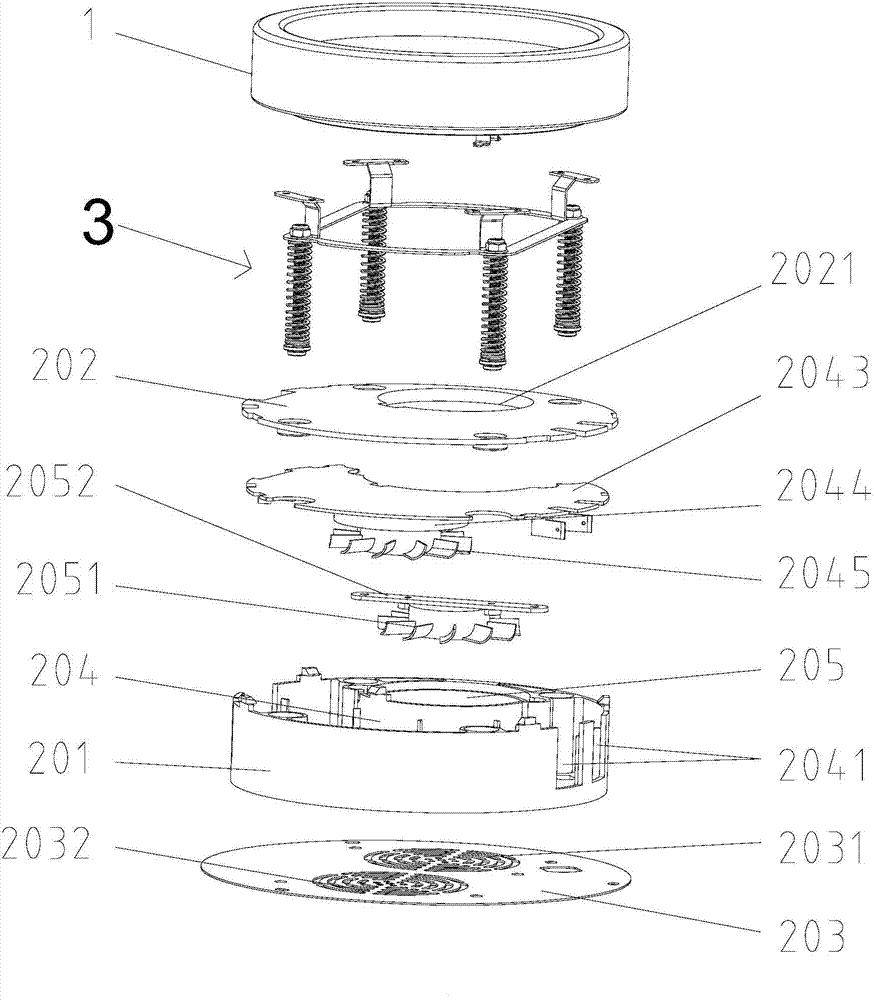

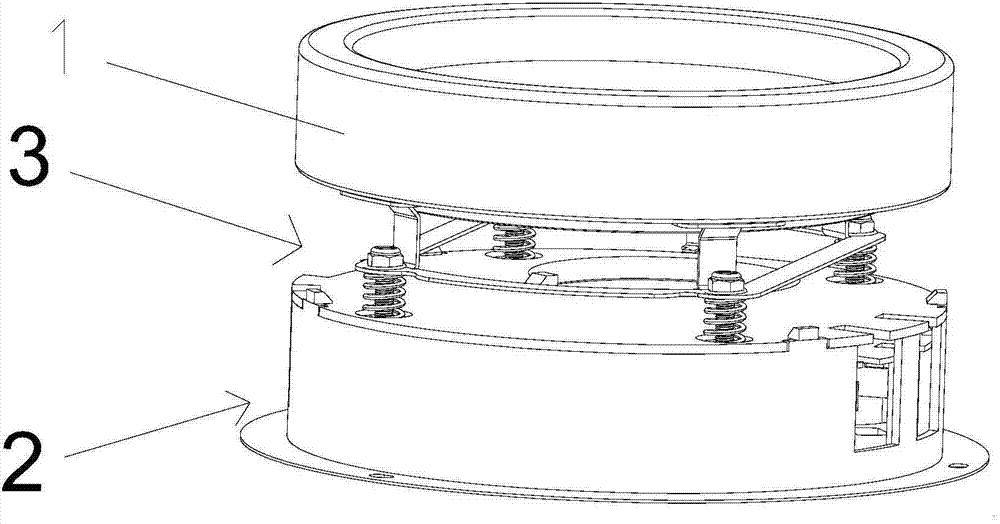

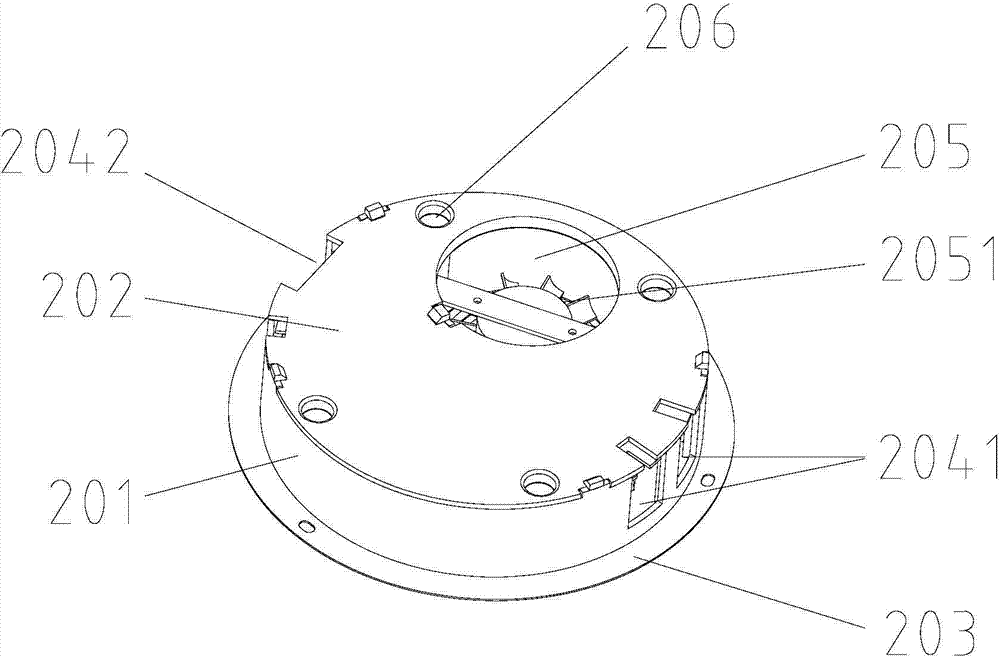

[0031] The technical scheme of the present invention is illustrated below in conjunction with accompanying drawing:

[0032] see Figure 1 to Figure 10 , the electric ceramic furnace core of the present invention includes a heating plate 1 and a core base 2, the heating plate 1 is supported above the core base 2 by a support member 3, and the core base 2 is provided with mutually isolated circuits The device room 204 and the heating disc cooling room 205, the circuit device room 204 is provided with a control circuit board 2043; the circuit device room 204 is provided with a device room air inlet 2040 and a device room air outlet 2014 and 2042, the circuit device The chamber 204 is provided with a circuit board heat dissipation fan 2045; the upper side of the heat dissipation chamber 205 is provided with a heat dissipation chamber air outlet, and the lower side of the heat dissipation chamber 205 is provided with a heat dissipation chamber air inlet 2050; A heating plate cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com