Cotton flow sensor

A flow sensor and cotton technology, applied in the field of flow sensors, can solve the problems that affect the flexibility of the cotton box load, affect the accuracy of data, and reduce the accuracy of production measurement, etc., and achieve strong anti-electromagnetic interference ability, low cost, Improved stability and accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

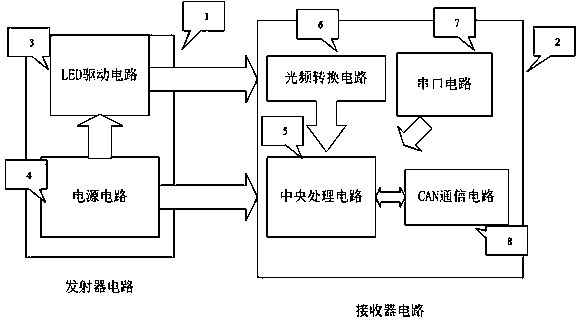

[0024] see figure 1 , the cotton flow sensor includes a transmitter circuit (1) and a receiver circuit (2). It is characterized in that: the transmitter circuit (1) is composed of a power supply circuit (4) connected to an LED drive circuit (3); the receiver circuit (2) is composed of a central processing circuit (5) connected to an optical frequency converter circuit (6), a serial port circuit (7) and a CAN communication circuit (8); the power supply circuit (4) is also connected to the LED drive circuit (3), the central processing circuit (5), the optical frequency conversion circuit (6), The serial port circuit (7), the CAN communication circuit (8); the LED drive circuit (3) is connected to the optical frequency conversion circuit (6).

Embodiment 2

[0025] Embodiment two: the present embodiment is basically the same as embodiment one, and the features are as follows:

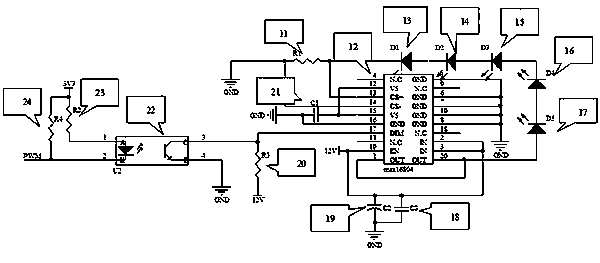

[0026] figure 2 Shows the LED drive circuit in the transmitter circuit (1): the central processing circuit (5) sends a PWM signal to the transmitter circuit, and the signal is connected to a resistor R4 (24) to a 3.3V voltage, and at the same time, the signal is connected to a photoelectric isolation The chip (22) has 2 pins, the 1 pin of the photoelectric isolation chip (22) is connected to a resistor R2 (23) to connect to 3.3V voltage, the 4 pin is connected to ground, and the 3 pin is connected to a resistor R3 (20) to connect to 12V voltage At the same time, this pin is connected to the 17th pin of a voltage regulation chip MAX16804 (12), and the 1st pin of the voltage regulation chip MAX16804 (12) is connected to the 20th pin to connect to the positive pole of the light-emitting diode D5 (17), and the negative pole of the light-emitting diode D5 (17) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com