Point joint tensile-shear strength testing device capable of applying multi-directional loads

A technology of strength testing and point joints, applied in the direction of using stable shear force to test material strength, using stable tension/pressure to test material strength, measuring device, etc., to achieve the effect of simple operation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

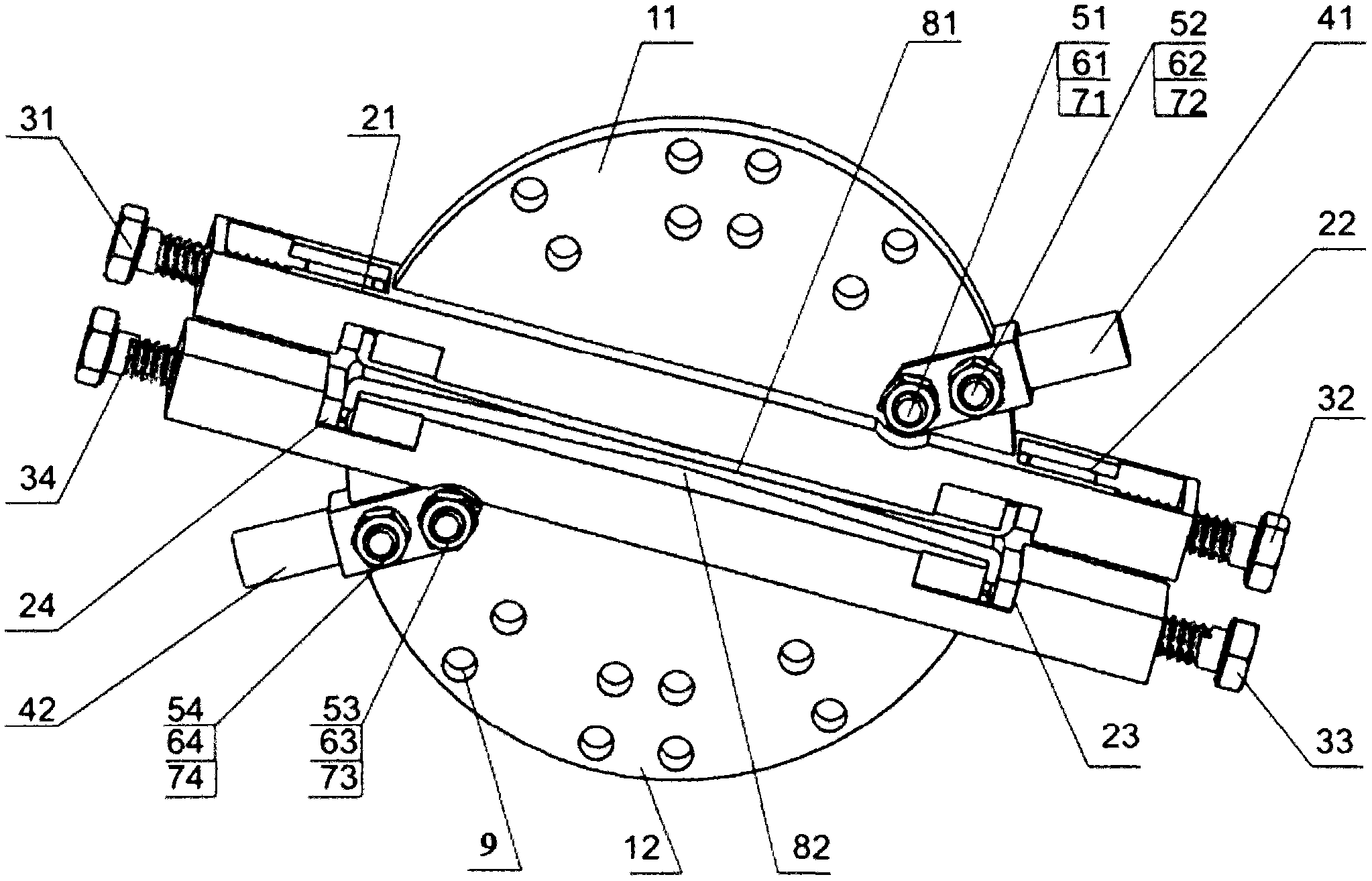

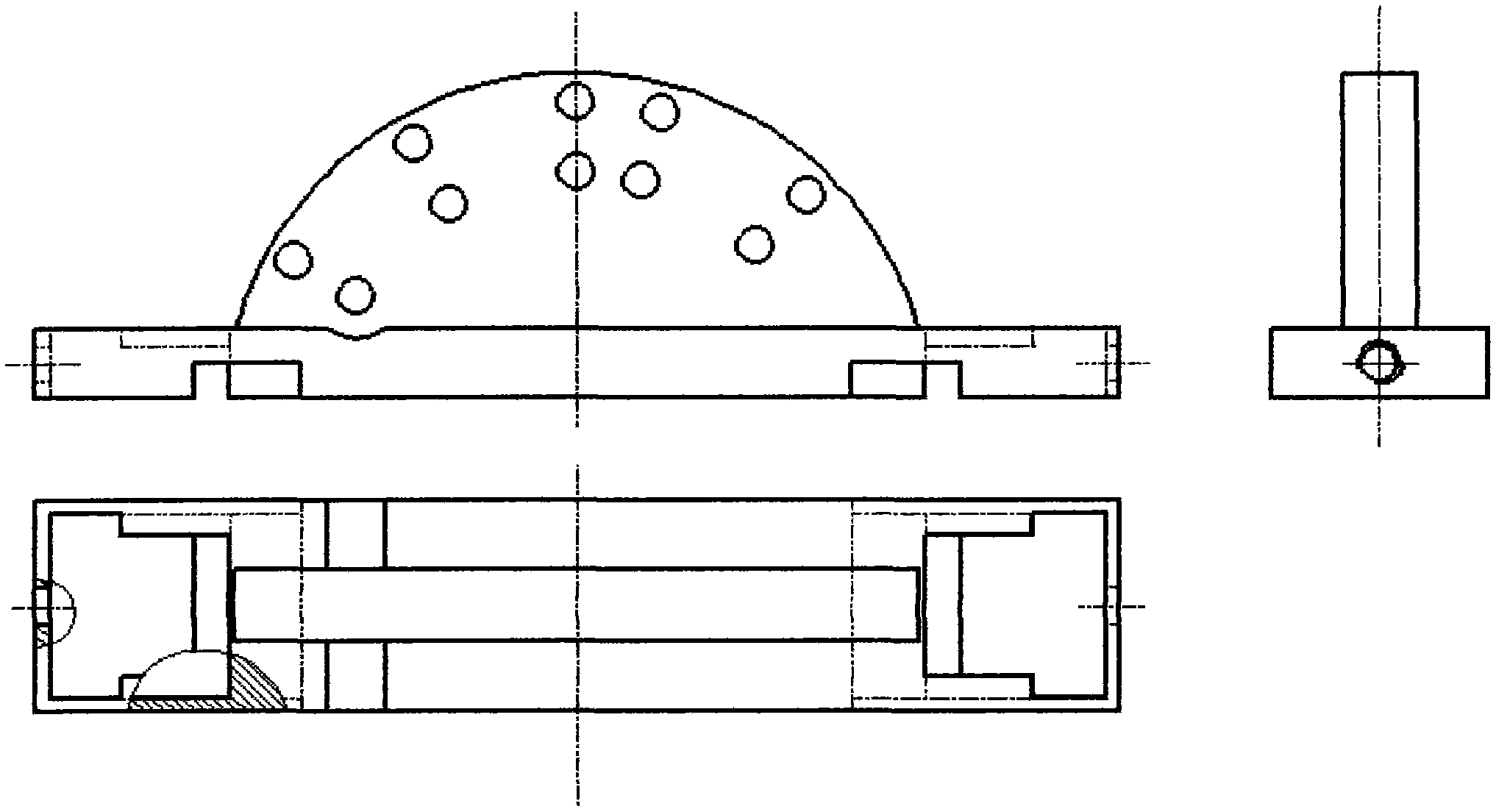

[0010] The device of the present invention and the schematic diagram of each part structure are as Figure 1 ~ Figure 3 As shown, it mainly includes clamping body 1, clamping block 2, fastening bolt 3, stressed block 4, and stressed block fasteners (bolt 5, washer 6 and nut 7) and the like.

[0011] The clamping block is placed in the clamping body, the force-bearing block is fixed on the clamping body with the force-bearing block fastener, and the fastening bolt is used for fastening the clamping block. When working, the plate is placed between the upper clamping body and the lower clamping body, and the clamping block is pushed by tightening the fastening bolts to fasten the plate. By applying force to the force blocks at different positions, the multi-directional tensile and shear load application test can be realized. During the experiment, the force direction of the upper force block, the force direction of the lower force block and the center of gravity of the plate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com