An improved manufacturing process of touch screen with pg structure

A manufacturing process, touch screen technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc. High, lower production costs, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A manufacturing process of a touch screen with an improved PG structure, which includes a front-end process and a back-end process:

[0057] A, front section process, it comprises the following steps successively:

[0058] Step A1, cleaning the DITO glass, the DITO glass includes a glass layer, the front side of the glass layer is provided with an ITO layer, and the back side of the glass layer is also provided with an ITO layer;

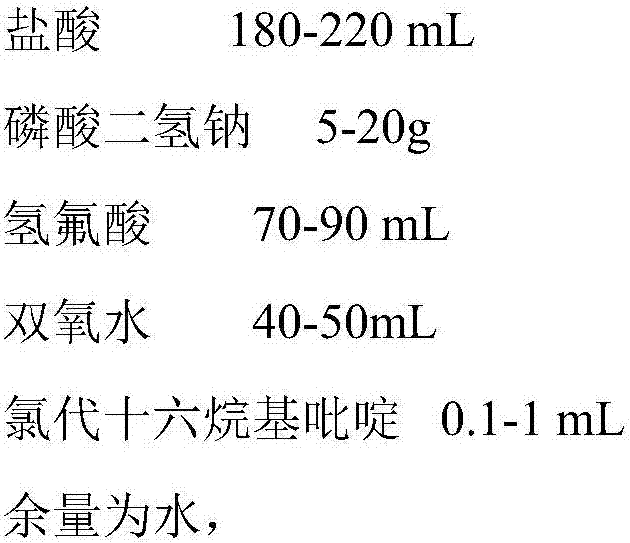

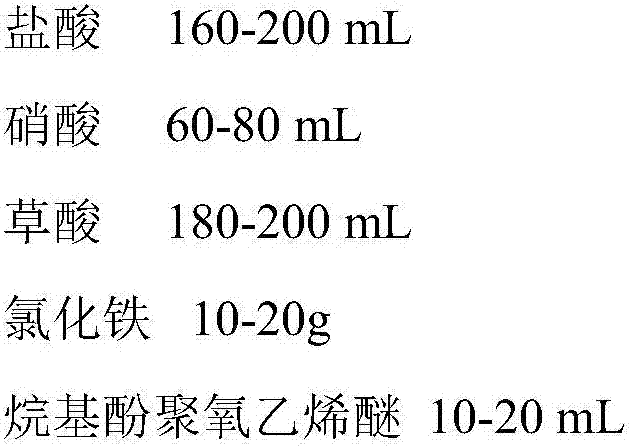

[0059] Step A2, the ITO layer of DITO glass front and back frame area is all printed acid-resistant ink, then the ITO layer of DITO glass front and back window area is etched for the first time with the first etchant, and the second etchant is used for the second Etching once to obtain DITO glass with ITO traces on the front and back, and then remove the acid-resistant ink with lye;

[0060] Step A3, printing protective glue on the front and back window areas of the etched DITO glass respectively, and silk-screening conductive silver paste o...

Embodiment 2

[0102] A manufacturing process of a touch screen with an improved PG structure, which includes a front-end process and a back-end process:

[0103] A, front section process, it comprises the following steps successively:

[0104] Step A1, cleaning the DITO glass, the DITO glass includes a glass layer, the front side of the glass layer is provided with an ITO layer, and the back side of the glass layer is also provided with an ITO layer;

[0105] Step A2, the ITO layer of DITO glass front and back frame area is all printed acid-resistant ink, then the ITO layer of DITO glass front and back window area is etched for the first time with the first etchant, and the second etchant is used for the second Etching once to obtain DITO glass with ITO traces on the front and back, and then remove the acid-resistant ink with lye;

[0106] Step A3, printing protective glue on the front and back window areas of the etched DITO glass respectively, and silk-screening conductive silver paste o...

Embodiment 3

[0148] A manufacturing process of a touch screen with an improved PG structure, which includes a front-end process and a back-end process:

[0149] A, front section process, it comprises the following steps successively:

[0150] Step A1, cleaning the DITO glass, the DITO glass includes a glass layer, the front side of the glass layer is provided with an ITO layer, and the back side of the glass layer is also provided with an ITO layer;

[0151] Step A2, the ITO layer of DITO glass front and back frame area is all printed acid-resistant ink, then the ITO layer of DITO glass front and back window area is etched for the first time with the first etchant, and the second etchant is used for the second Etching once to obtain DITO glass with ITO traces on the front and back, and then remove the acid-resistant ink with lye;

[0152] Step A3, printing protective glue on the front and back window areas of the etched DITO glass respectively, and silk-screening conductive silver paste o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com