Electromagnetic relay for automobile

An electromagnetic relay, automotive technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of time-consuming welding methods, spot welding, and low production efficiency, so as to improve quality and service life, and improve production Efficiency and simplification of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

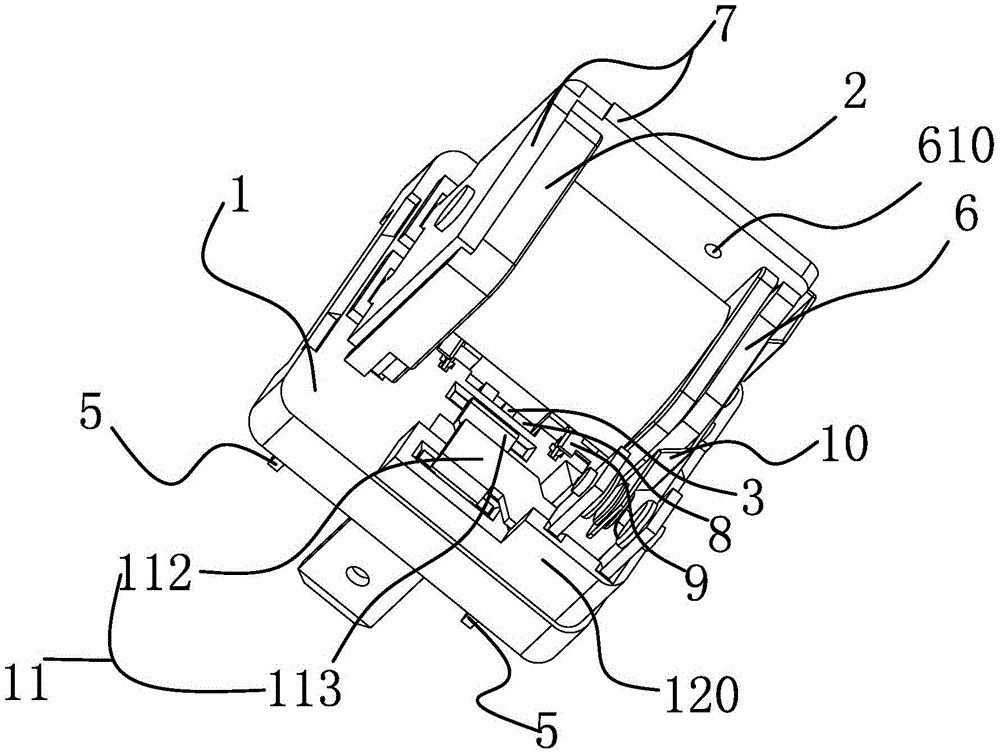

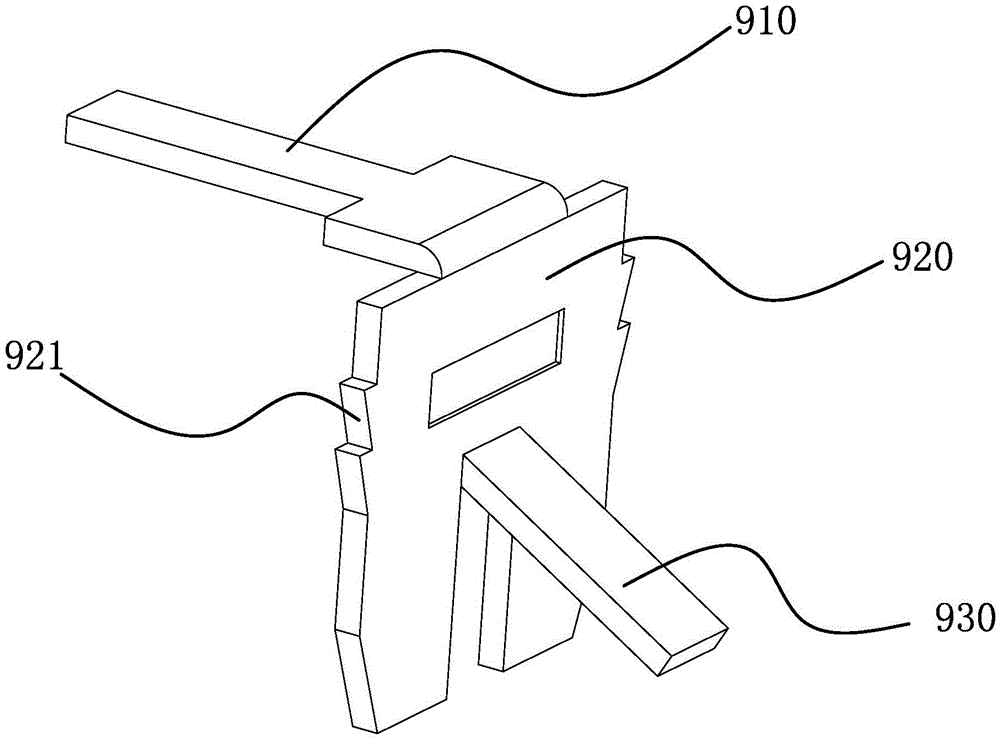

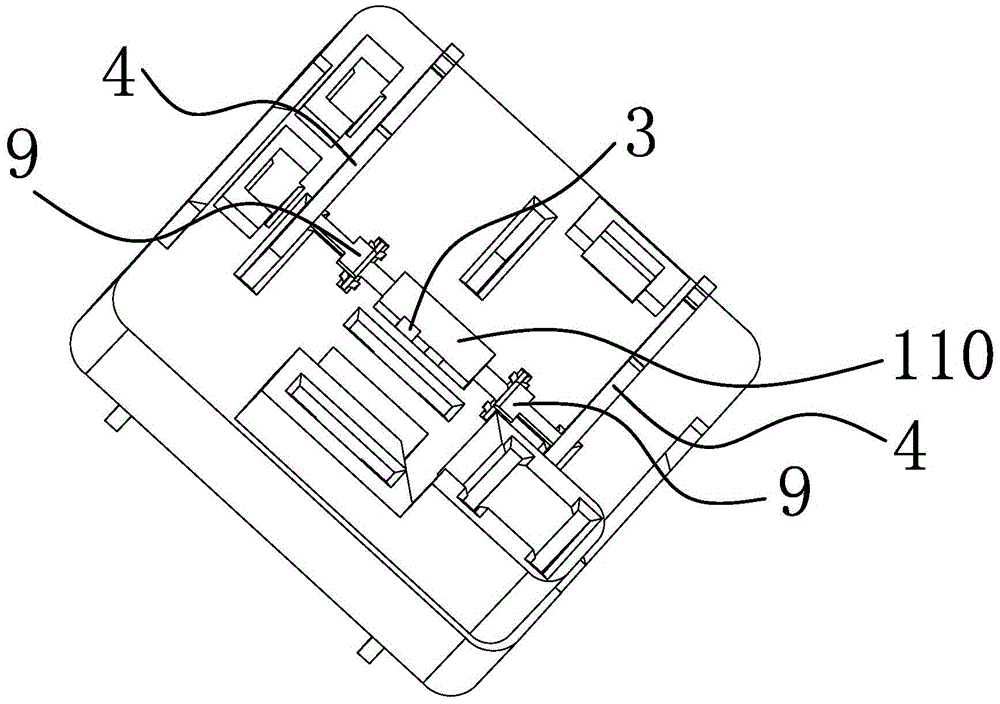

[0028] Such as figure 1 As shown, an electromagnetic relay for automobiles includes a base 1, an H-shaped coil frame 2 with a coil, an electronic component 3, a lead piece 4, a pin 5, an armature 6 and a yoke 7, and the H-shaped coil frame 2 is installed on the base On the seat 1, the bottom ends of both sides of the H-shaped coil frame 2 are provided with a first notch for inserting the lead piece 4, the electronic component 3 is integrated into the circuit board 8, and the circuit board 8 is arranged on the base 1, and the circuit board 8 A metal sheet 9 is connected between the lead piece 4, the yoke 7 and the armature 6 are inserted into each other and inserted on the base 1, one side of the yoke 7 is attached to the side wall of the H-shaped coil frame 2, and the armature 6 Fitted with the other side wall of the H-shaped coil frame 2, the surface of the armature 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com