Lamination tool for exciter stator iron core

A technology of laminating tooling and machine stators, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of increased workload, cumbersome operation, and heavy tooling, and achieve the effects of reducing labor intensity, overcoming cumbersome operations, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

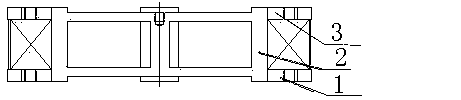

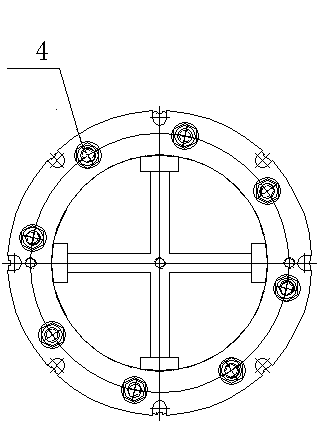

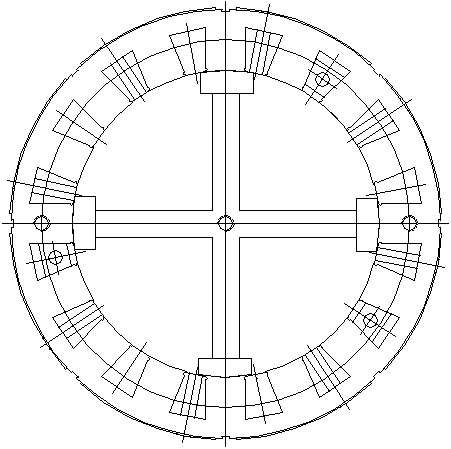

[0011] Such as figure 1 , 2 , 3, the present invention includes a base 1, a core 2 and a pressing plate 3, the core 2 is placed in the base 1, the core 2 is welded by steel plates or round steel, and the outer circle size of the core 2 is the same as that to be laminated The dimensions of the inner circle of the stator punch match, that is, a gap fit is adopted between the two. The base 1 is a circular plate seat with an inner hole, and the diameter of the inner hole of the base 1 matches the diameter of the outer circle of the core 2; On the same circumference of the base 1, a plurality of T-bolt slots are evenly provided, as well as slot-shaped adjustment block positioning slots, avoidance buckle slots and hoisting holes matching the stator punches to be laminated; the pressure plate 3 is set on the core body 2, the pressure plate 3 and the base 1 are connected by T-bolts 4, and the pressure plate 3 is provided with T-bolt holes corresponding to the T-bolt chute on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com