Composition comprising fermentation products from bacillus subtilis

A technology of Bacillus subtilis and fermentation products, applied in the direction of fermentation, biocide-containing paint, microbial-based methods, etc., can solve the problems of microbial contamination of products, prolongation of time period, etc., and achieve the goal of preventing pollutants and/or microbial contamination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0624] Example 1 - Preparation of antibacterial samples

[0625] Growth of Antimicrobial Strains

[0626] Strains: Bacillus subtilis 22C-P1 (DCS 1579), 15A-P4 (DCS 1580), 3A-P4 (DCS 1581), LSSAO1 (DCS 1582), ABP278 (DCS 1583) and BS18 (DCS 1584) from blood agar Resuscitation from deep-frozen stock cultures. Isolated colonies from each culture were streaked on CASO agar and incubated aerobically at 32°C for 24 hours. One colony of each culture was transferred to 10 mL of CASO broth in a 50 mL SARSTEDT tube and incubated for 24 hours at 32°C with tilting shaking at 130 rpm. 0.5 mL of the growth culture was transferred to 50 mL of CASO broth in a 250 mL Erlenmeyer flask and incubated at 32°C with shaking at 130 rpm for 24 hours.

[0627] Preparation of Antibacterial Supernatant Samples

[0628] Fully grown cultures were centrifuged twice at 10.000 xg for 10 minutes each. The supernatant was filter sterilized (using vacuum) and the filtrate was used immediately.

example 2

[0629] Example 2 - Inhibition Range Determination

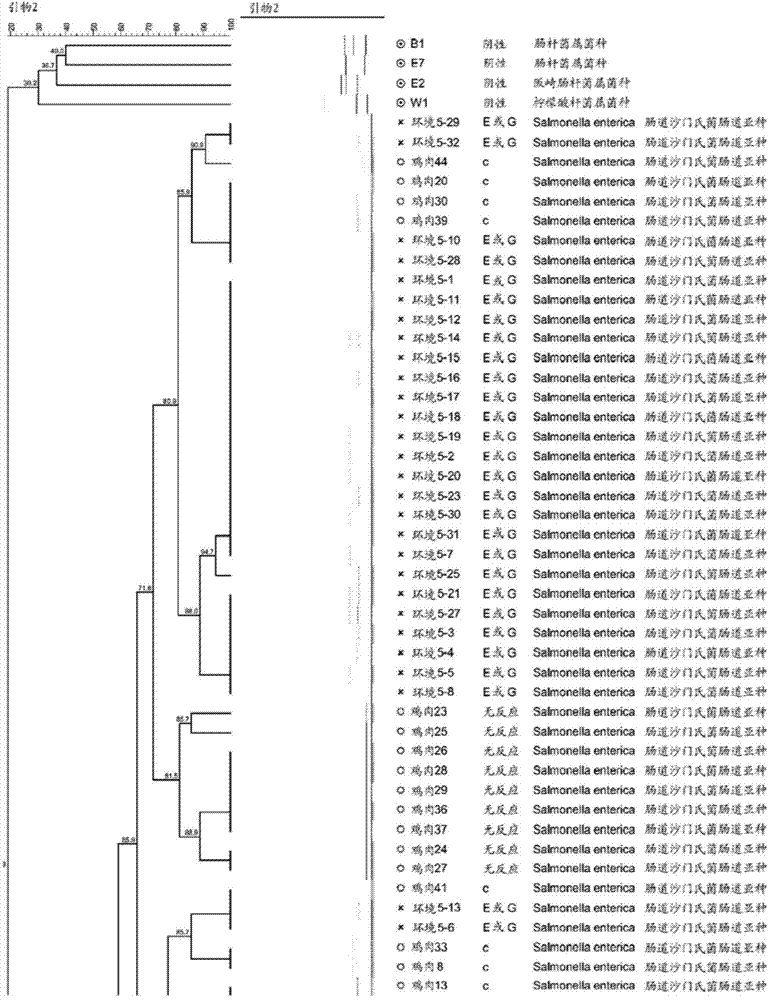

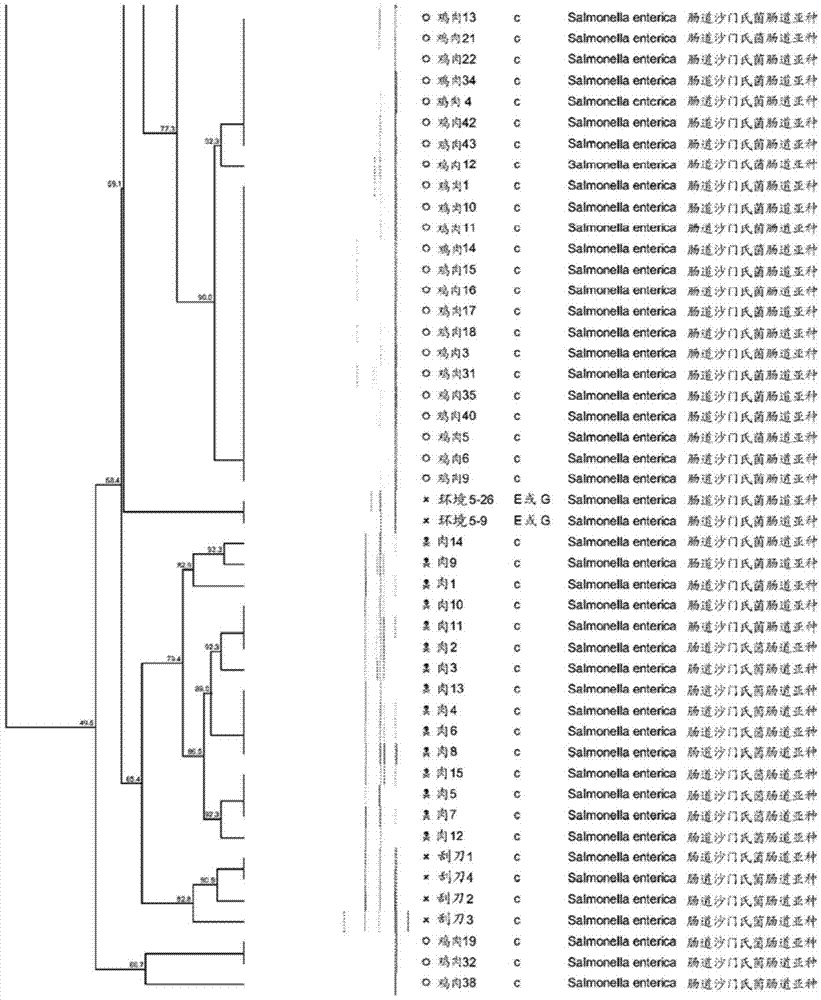

[0630] The well diffusion assay was used to assess the extent of inhibition of cell-free supernatants (CFS) prepared in Example 1 against various target microorganisms (Table 1). Prepare one plate for each indicator microorganism. 30 mL of molten agar medium containing 3 mL of 2M sodium phosphate (pH 6.5) was inoculated with 150 μl of the fully grown overnight culture and mixed well. Pour the suspension into the omnitray and let it settle for 30 minutes. Six wells were cut in the agar and left to dry open for another 30 minutes in the LAF stand. Each duplicate well was filled with 100 μl of supernatant as previously prepared and incubated at the corresponding temperature, time and conditions as shown in Table 1. After the incubation time, the diameter of the inhibition zone was assessed and divided into inhibitory populations. Activity is marked as "+" for zone diameters up to 10 mm including the aperture, "++" for zone...

example 3

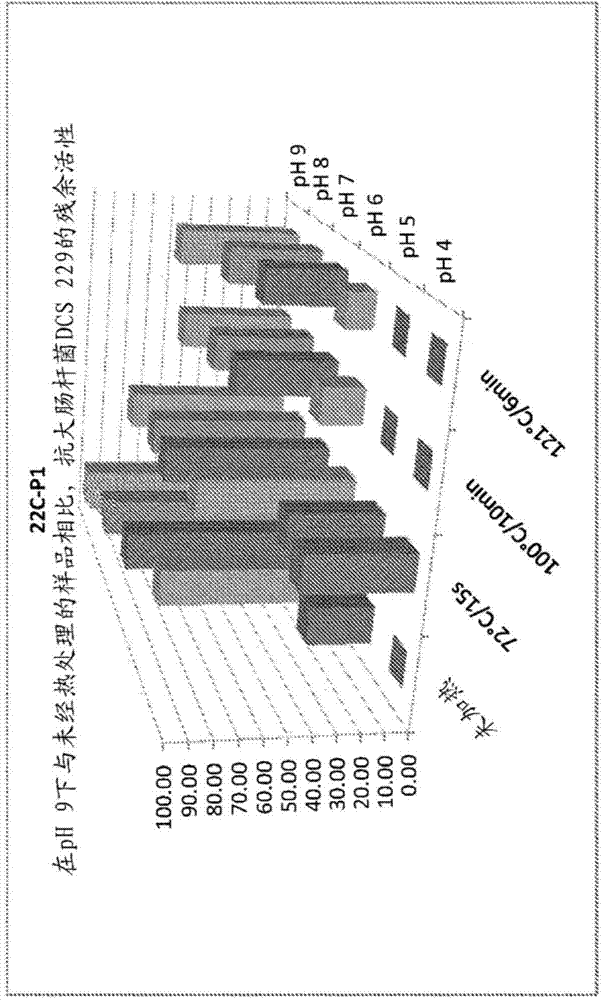

[0645] Example 3 - Sensitivity of activity to heat treatment and various pH

[0646] 30 mL of CFS for each strain was divided into 6 aliquots of 5 mL and the pH was adjusted to pH 4, 5, 6, 7, 8 or 9 using 5M NaOH or 5M HCl. Each pH adjusted 5 mL aliquot was filter sterilized, divided into 5 aliquots of 0.8 mL and stored at 4°C until use.

[0647]Heat treatment was applied as described in Table 5 for each CFS. Six aliquots (one for each pH value) were heat treated at 72°C for 15 seconds. Temperature was monitored using a temperature probe through a hole in the lid in an eppendorf tube filled with 0.8 mL of CASO broth. 15 seconds were counted from the moment the temperature reached 72°C. Another set of 6 aliquots was heat treated at 100°C for 10 minutes. Temperature was monitored using a temperature probe through a hole in the lid in an eppendorf tube filled with 0.8 mL of CASO broth. Ten minutes were counted from the moment the temperature reached 95°C. Six aliquots wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com