Colored contact lens

A contact lens and lens technology, applied in glasses/goggles, optics, instruments, etc., can solve problems such as hindering the oxygen permeability of lens raw materials, and achieve the effect of restraining deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Hereinafter, several examples are shown in order to clarify this invention more concretely.

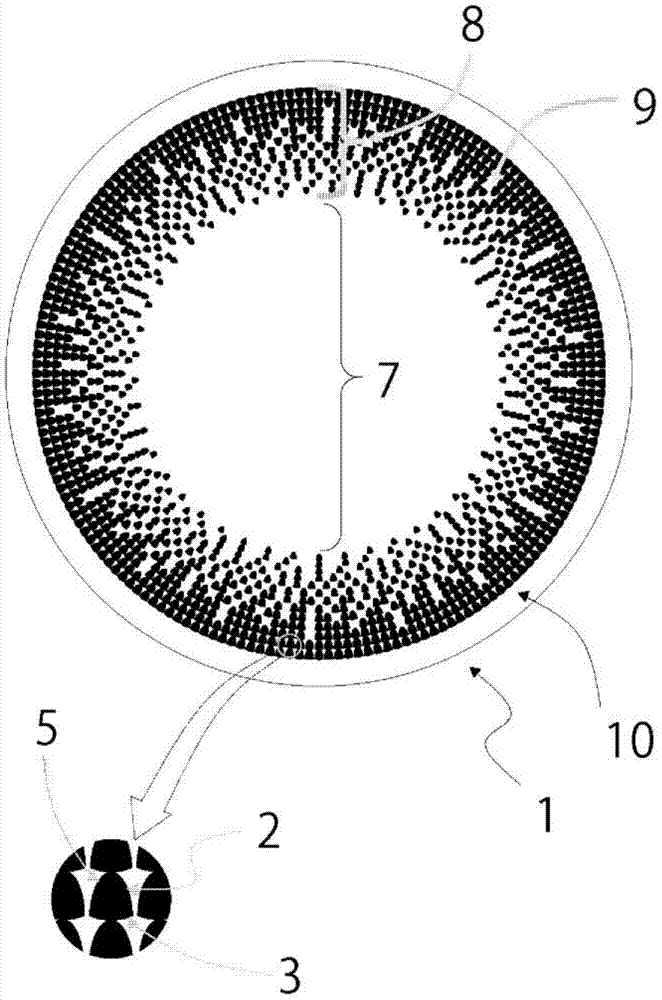

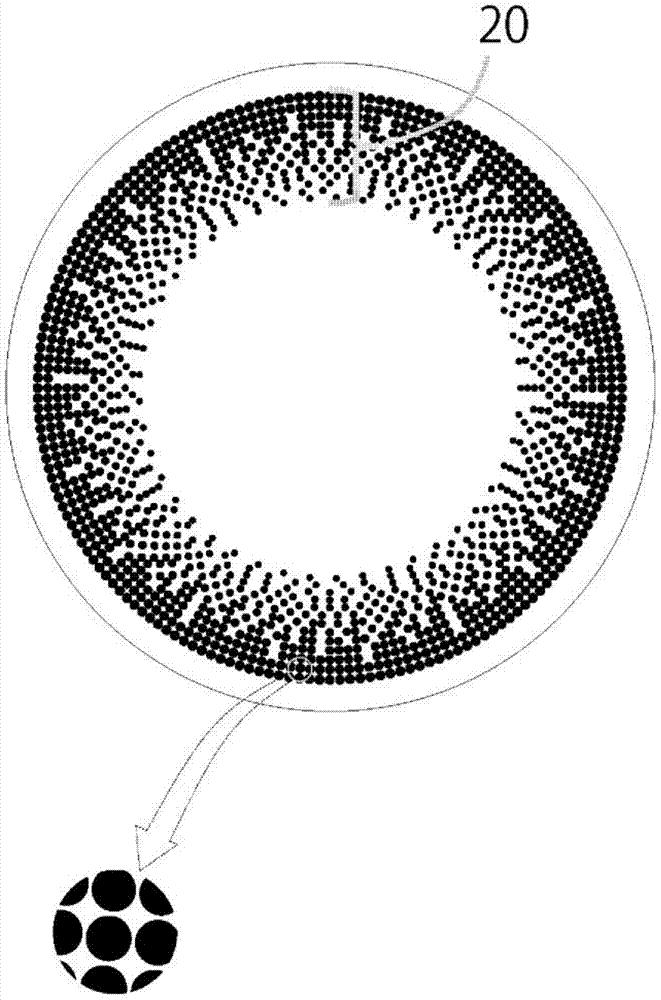

[0091] Apart from figure 1 In addition to the design patterns shown in (Example 1), by image 3 Point (20) shown in (Comparative Example 1), Figure 4 Curve (25) shown in (Comparative Example 2), Figure 5 The rod-shaped (30) shown in (Comparative Example 3), Image 6 (Comparative Example 4) For each design of the annular shape (35), colored contact lenses were produced, and the subjects wore them on one eye, and compared the difference in appearance of the other eye with the naked eye using a mirror. In addition, the wearing eye was changed, and both eyes were evaluated in the same manner.

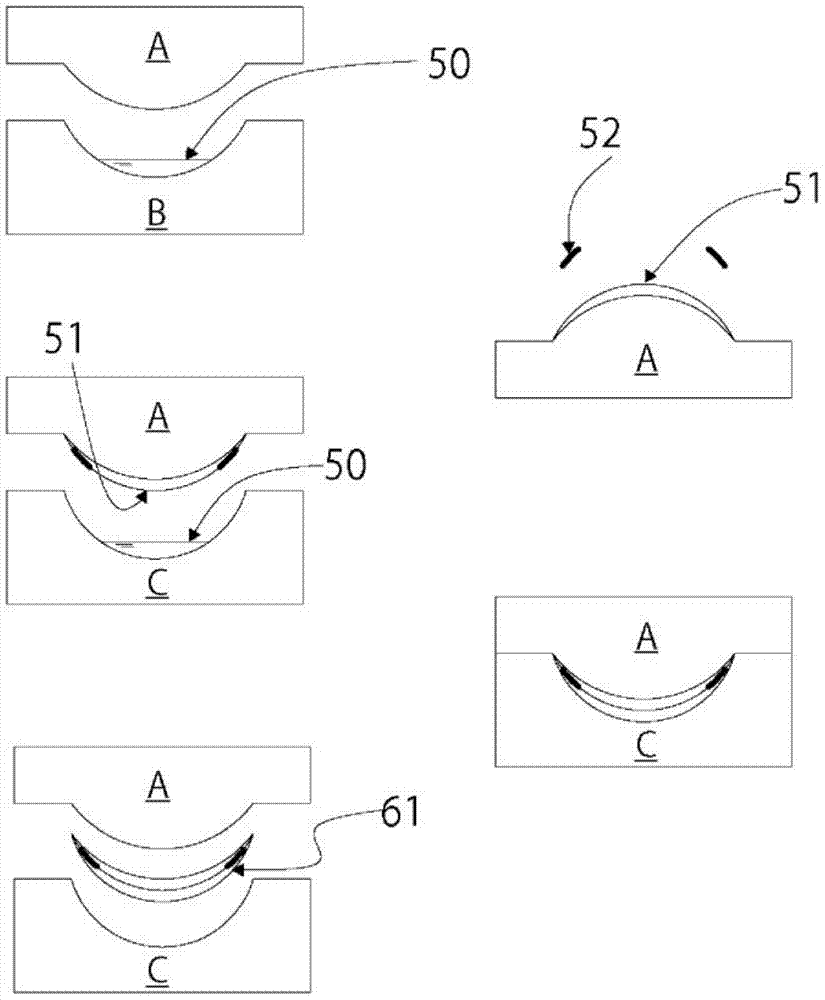

[0092] Tinted contact lenses are produced as follows.

[0093]A contact lens forming monomer composition (2-hydroxyethyl methacrylate (hereinafter referred to as 2-HEMA) 59w / w%, glycerin methacrylate ( Hereinafter referred to as GMA) 30w / w%, ethylene glycol dimethacrylate (hereinafte...

Embodiment 2

[0110] In addition to will figure 1 The design pattern becomes Figure 7 ~ Figure 10 Except for the design shown, it carried out similarly to Example 1, and each colored contact lens was produced. Figure 7 ~ Figure 10 All of the designs are examples in which various changes are made to the curvature of the rear end side with respect to the shape of the colored opaque portion, and are linear (13)( Figure 7 , Figure 8 ), the shape curved toward the center of the lens (33)( Figure 9 ), the shape connecting two points on the arc with a straight line (23)( Figure 10 ). It should be noted, Figure 7 and Figure 8 The difference is that, Figure 7 is an example in which the size of the colored opaque portion gradually decreases toward the center of the lens. In contrast, Figure 8 , is an example of not changing the size. For each of these lenses, the same evaluation test as in Example 1 was performed. The results are shown in Table 2.

[0111] 【Table 2】

[0112] ...

Embodiment 3

[0115] In the same manner as in Example 1, the concave mold C made of PP was fitted with the convex mold A to carry out polymerization. The concave mold C was filled with 60 µl of the above contact lens-forming monomer composition. In addition, it is designed so that the polymer formed in the concave mold C is thicker than the lens of Example 1. When the female die C is separated from the male die A, the polymer adheres to the male die A. This die was fixed on the shaft of a lathe for contact lens production, and rotated at 300 RPM, and the polymer was cut with a diamond knife, and finished into a contact lens shape. In the same manner as in Example 1, the polymer-adhered punch A finished into a contact lens shape was immersed in 5 ml of purified water, and the same treatment was performed to inspect the polymer. Based on PW: -3.00D, CT: 0.11mm, and diameter: 14.2mm, there is a figure 1 tinted contact lenses with a scale pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com