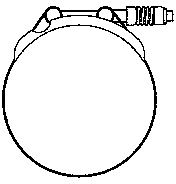

Worm-gear clamp with spiral spring

A technology of helical spring and worm gear, which is applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc. It can solve the problems of difficult processing, low installation efficiency, small spring adjustment, etc., and reach the installation position The effect of low requirements, small space occupied by bolts and large spring adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in combination with specific embodiments.

[0023] As a preferred embodiment of the present invention, such as Figure 7-Figure 8As shown, a helical spring turbine worm clamp includes a band 1 and a band seat 2, and the inner cavity of the band seat 2 has a cylindrical part for installing the worm and a grooved part for fixing the band 1, One end of the band 1 is fixed in the groove-shaped part of the band seat 2, and the other end of the band 1 is provided with a section of worm teeth along the length direction. The belt 1 is bent to form a circular turbine, and a worm 3 is installed on the hoop 2. The worm 3 has a rotating force application end positioned outside the hoop 2 and an engaging end inserted into the inner cavity of the cylindrical part of the hoop 2. On the engaging end It has a section of meshing teeth and meshes with the worm teeth on the band 1, the rotating force end of the worm 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com