On-line measure apparatus for water content and density and measure method thereof

A technology of measuring device and measuring method, which is applied in the direction of measuring device, specific gravity measurement, instrument, etc., can solve the problems of inability to monitor the water content of oil products in real time, user loss, long time, etc., to solve the problem of quality control, convenient and flexible detection, Novel and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

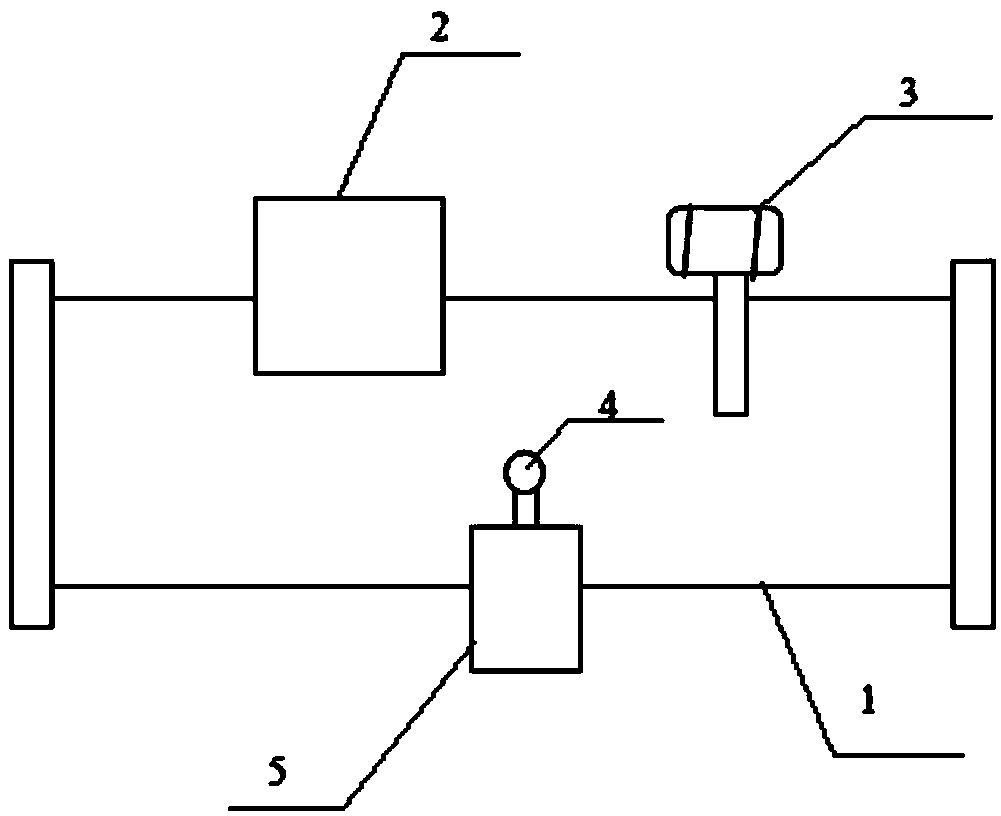

[0024] Such as figure 1 As shown, an on-line measuring device for moisture content and density of the present invention includes a moisture analyzer 2 and a density meter 3, and also includes a host computer (not shown in the figure), a controller (not shown in the figure), a measuring pipeline 1 and automatic sampling device; the host computer is connected with the controller, moisture analyzer 2, density meter 3 and automatic sampling device respectively; the controller is connected with the moisture analyzer 2, density meter 3, automatic sampling device Connect respectively; Described automatic sampling device, moisture analyzer 2 and density meter 3 are respectively installed on the measuring pipeline 1, wherein, described moisture analyzer 2 and density meter 3 are arranged on the top of measuring pipeline 1, and described automatic sampling The device is arranged on the side of the measuring pipeline 1, the water content analyzer 2 and the density meter 3 are arranged op...

Embodiment 2

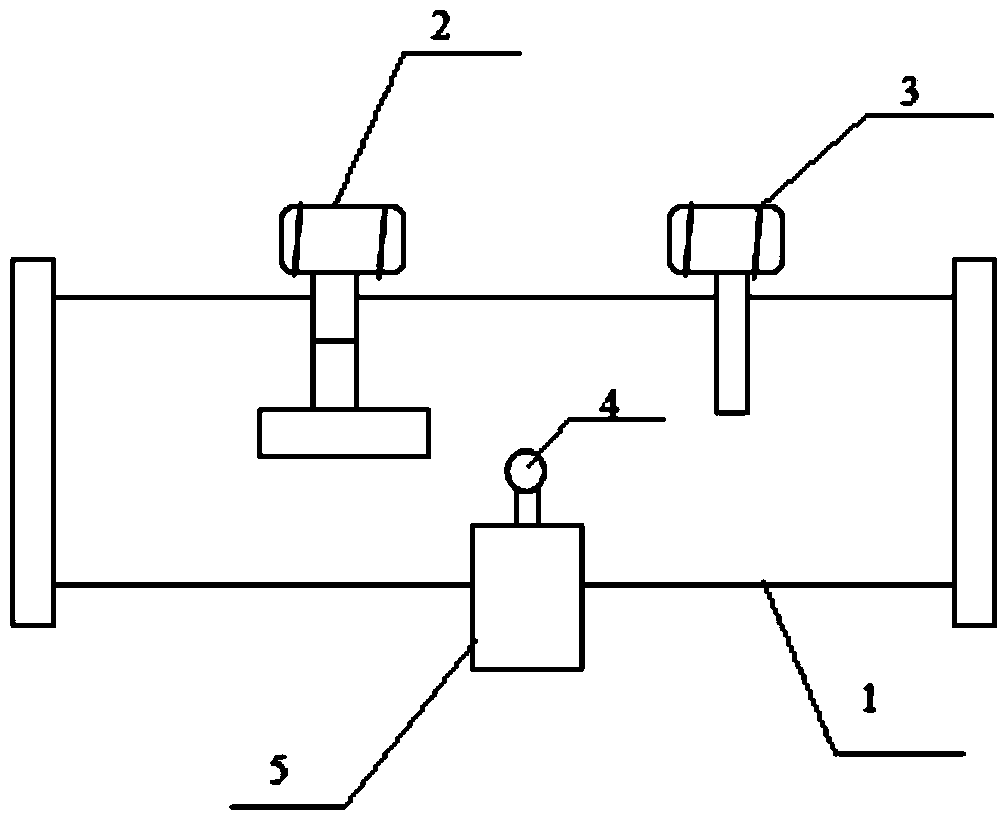

[0030] Such as figure 2 As shown, an on-line measuring device for moisture content and density of the present invention has the same basic structure and application as in Example 1. In order to achieve consistency in oil product measurement, specifically: the water content analyzer 2 includes a probe, and the The probe is a pipe section, and the probe is parallel to the measuring pipeline 1, so that the water content analyzer 2 can perform real-time detection along the flow direction of the oil in the measuring pipeline 1, reducing the influence of flow resistance on the instrument.

Embodiment 3

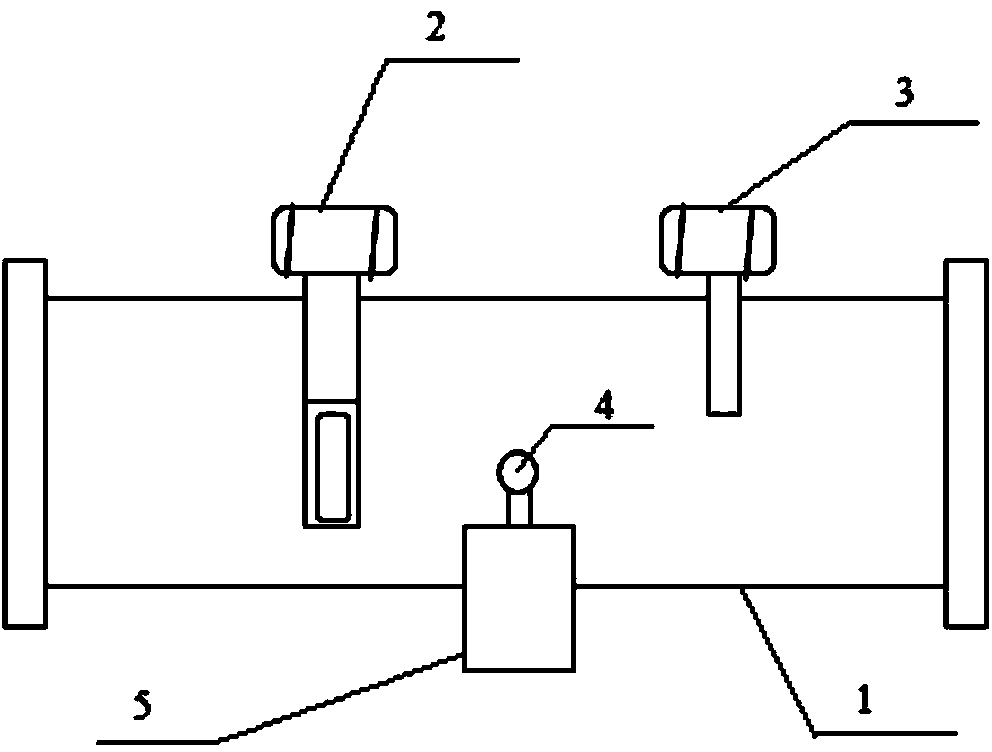

[0032] Such as image 3 As shown, an on-line measuring device for moisture content and density of the present invention has the same basic structure and application as in Example 1. In order to achieve consistency in oil product measurement, specifically: the water content analyzer 2 includes a probe, and the The probe is plug-in type, and the probe is perpendicular to the measuring pipeline 1, so that the water content analyzer 2 can penetrate deeply into the measuring pipeline 1 to detect oil products in real time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com