Cathode assembly of magnetron for microwave oven and magnetron thereof

A technology of cathode components and magnetrons, applied in the field of magnetrons, can solve problems such as filament pollution and affect the quality of magnetrons, and achieve the effect of avoiding filament pollution and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

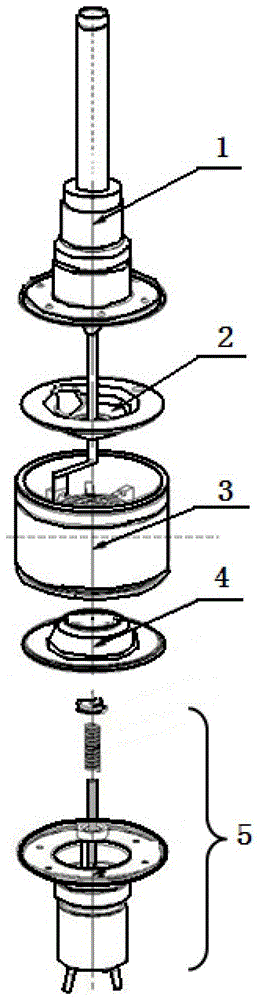

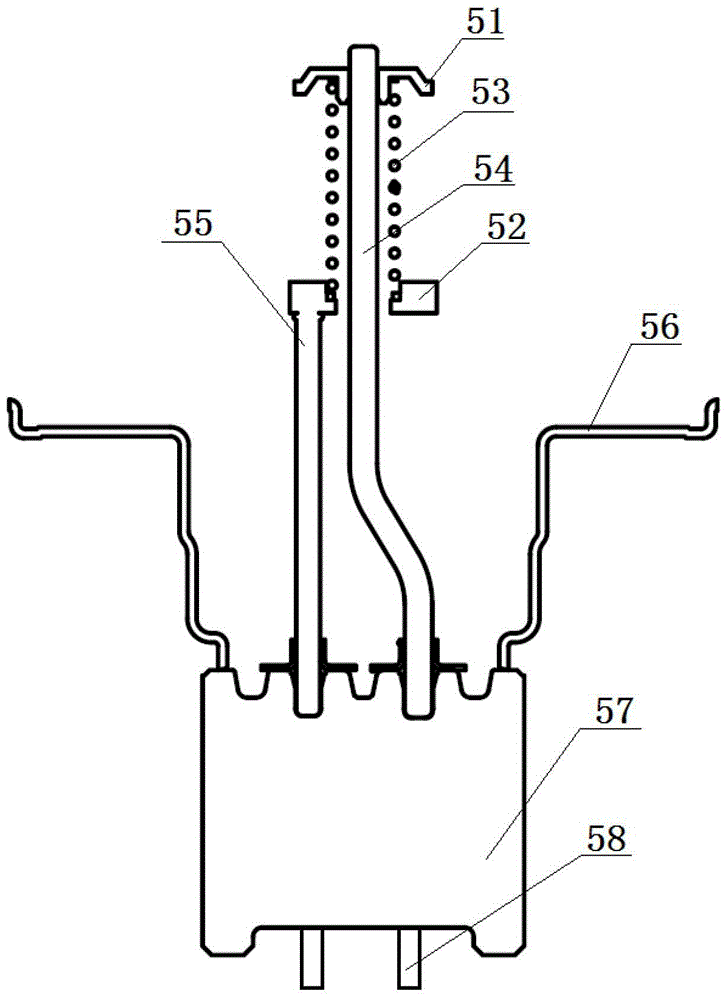

[0029] The cathode assembly of the magnetron for a microwave oven and the magnetron thereof of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0030] The cathode of the magnetron is the emitter of electrons. The performance of the cathode has a great influence on the working characteristics and life of the tube, and it is regarded as the heart of the whole tube.

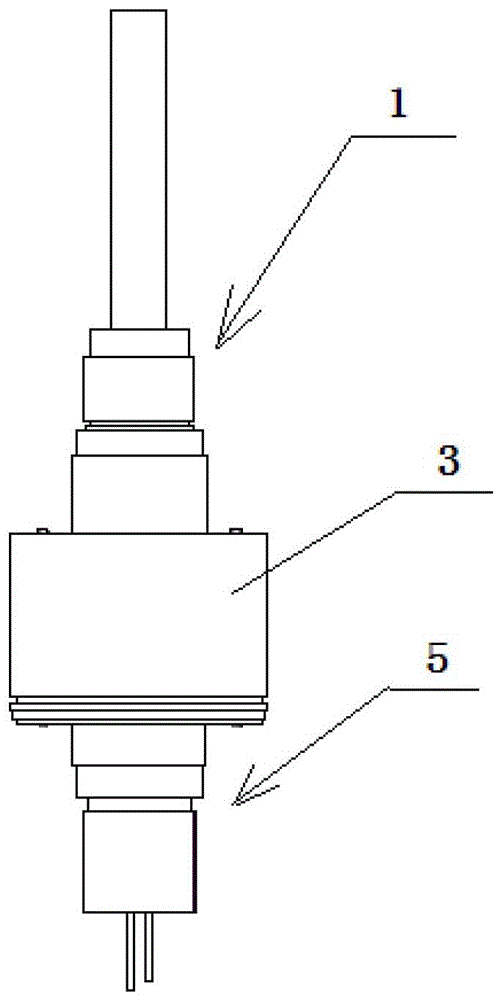

[0031] The cathode assembly and the magnetron of the magnetron used in the microwave oven of the present invention, through the magnetron used in the microwave oven, the storage position of the titanium liquid is redesigned to achieve the control of the magnetron caused by the excessive flow of the titanium liquid. Quality problems, thereby reducing the defect rate of the magnetron.

[0032] Such as Figure 5 As shown, the cathode assembly of the magnetron for microwave oven of the present invention includes ceramics 57 inserted with two conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com