Printed circuit board component and manufacturing method thereof

A technology of printed boards and components, which is applied in the direction of printed circuit parts, contact parts, printed circuits connected with non-printed electrical components, etc., can solve the problems of poor isolation of radio frequency contacts, and solve the problem of poor isolation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

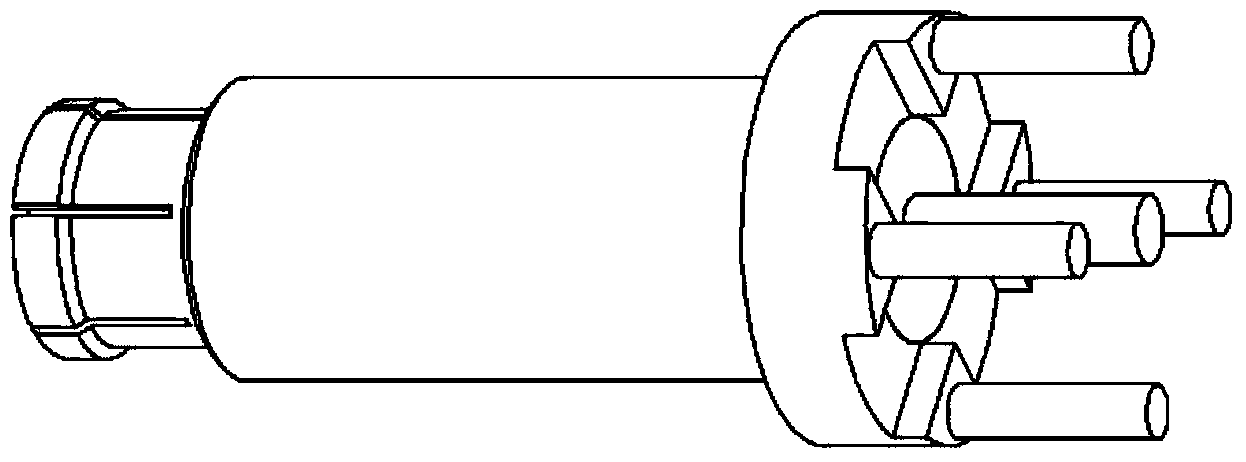

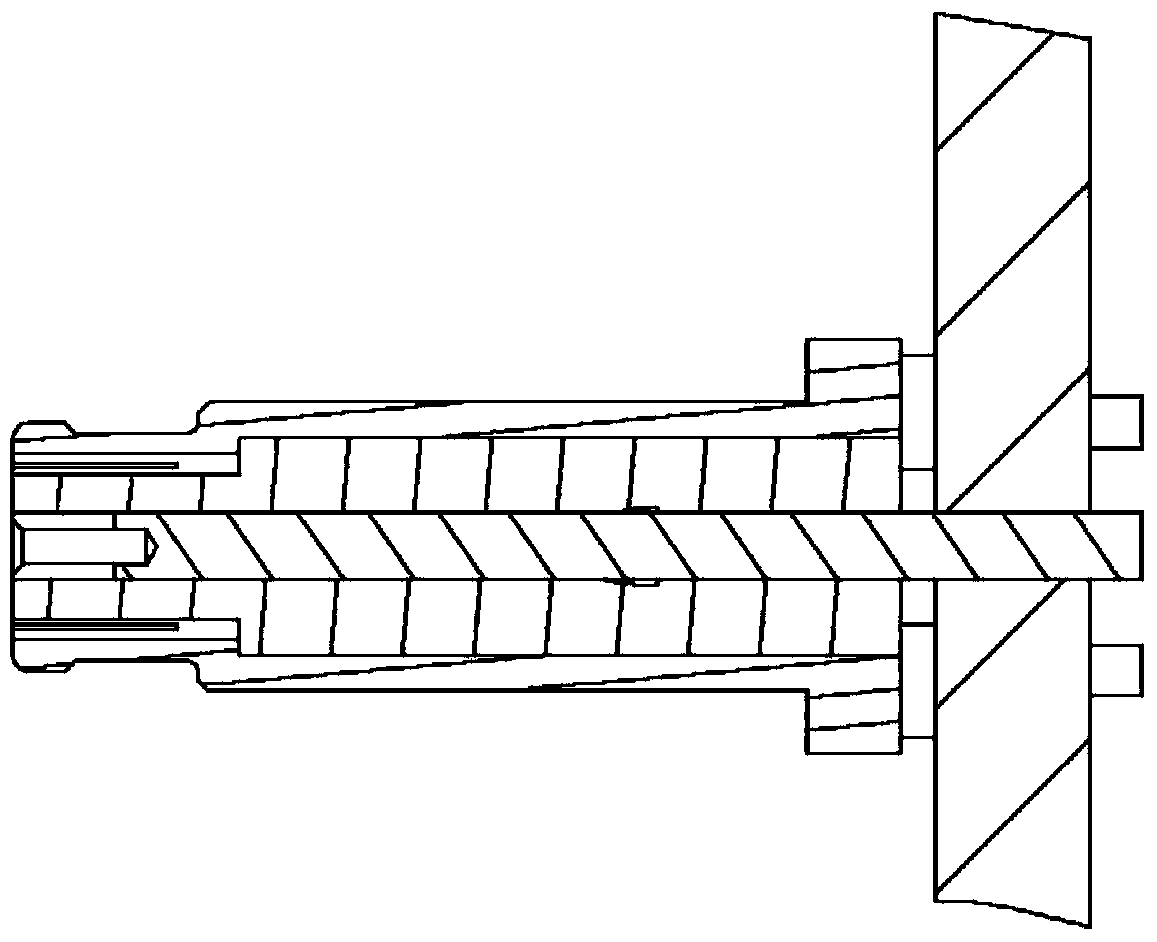

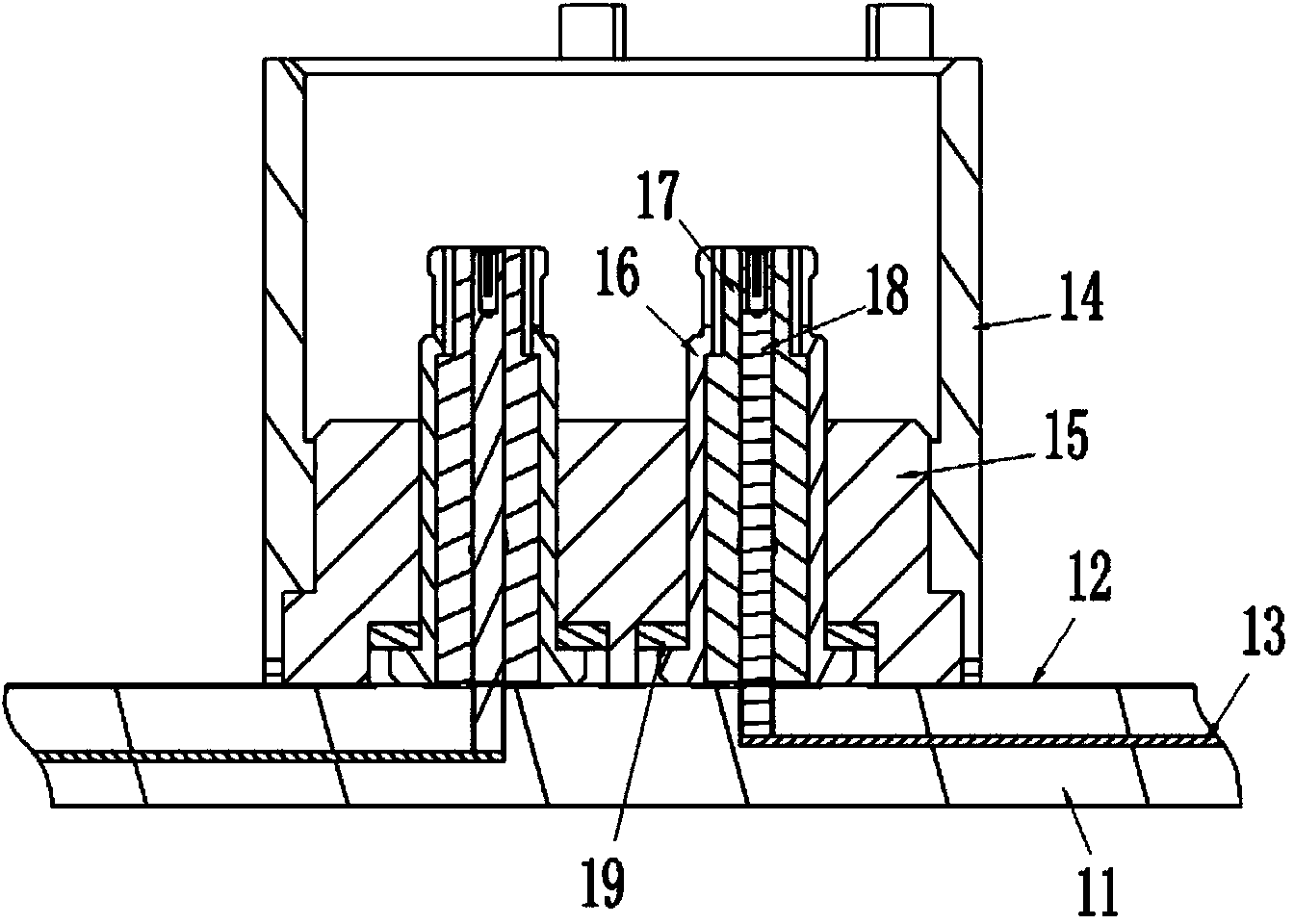

[0020] Examples of printed board components, such as image 3 As shown, the printed board component includes a printed board 11 and a radio frequency connector fixedly mounted on the printed board 11, and the radio frequency connector has a front end as a plug-in terminal.

[0021] The radio frequency connector is located on the front side of the printed board 11. The front side of the printed board 11 is provided with a shielding conductive layer 12, and a signal conductive layer 13 is provided inside. In addition, the front side of the printed board 11 is also provided with blind holes. The depth of the blind hole should be the bottom of the hole. Reach the signal conductive layer 13.

[0022] The radio frequency connector includes a housing part and a radio frequency contact. The housing components include a housing 14 and a contact mounting body 15 provided in the housing 14. In this embodiment, the housing 14 is provided with a stepped surface facing backward, and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com