A kind of Cantonese sausage production process

A production process, the technology of Cantonese-style sausage, applied in the field of food processing, can solve the problems of shortening the production time of Cantonese-style sausage, accelerating the fermentation process of Cantonese-style sausage, and the imbalance of flavor substances, so as to shorten the production time, save production cost and taste good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

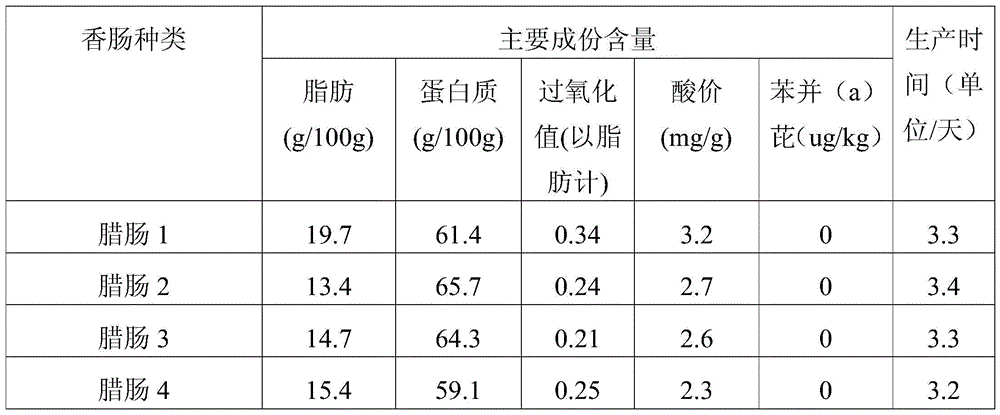

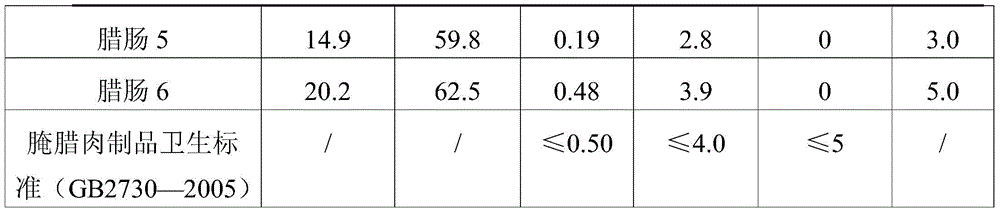

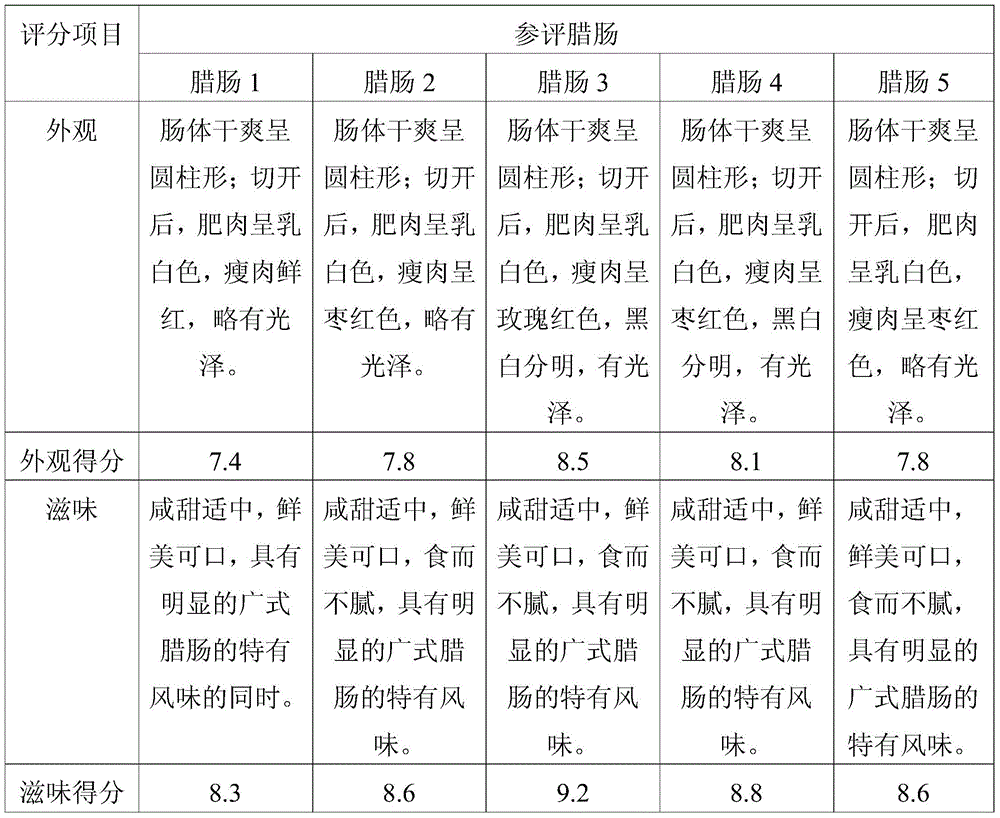

Examples

Embodiment 1

[0029] a. Preparation of fermentation bacteria: the fermentation bacteria include Lactobacillus pentosus, Pediococcus lactis, Inococcus, Staphylococcus xylosus, Staphylococcus mimetic, Micrococcus mutans and Staphylococcus epidermidis; cultivate the fermentation bacteria species respectively ,stand-by;

[0030] b. Preparation of raw materials: weigh lean meat and fat meat, then mince and mix the lean meat and fat meat to obtain raw meat for later use; prepare animal casings, clean them, drain the water, and wait for Use; The mass ratio of lean meat and fat meat is 6:2;

[0031] c, preparation of ingredients: the ingredients are made of the following components by weight: 80 parts by weight of rock sugar, 20 parts by weight of salt, 10 parts by weight of white wine, 5 parts by weight of pepper, 2 parts by weight of monosodium glutamate, 2 parts by weight of minced ginger and 2 parts by weight of mashed garlic; weigh the above-mentioned salt, rock sugar, white wine, pepper, mon...

Embodiment 2

[0035] a. Preparation of fermentation bacteria: the fermentation bacteria include Lactobacillus pentosus, Pediococcus lactis, Inococcus, Staphylococcus xylosus, Staphylococcus mimetic, Micrococcus mutans and Staphylococcus epidermidis; cultivate the fermentation bacteria species respectively ,stand-by;

[0036] b. Preparation of raw materials: weigh lean meat and fat meat, then mince and mix the lean meat and fat meat to obtain raw meat for later use; prepare animal casings, clean them, drain the water, and wait for Use; The mass ratio of lean meat and fatty meat is 6:1;

[0037] c, preparation of ingredients: the ingredients are made of the following components by weight: 85 parts by weight of rock sugar, 23 parts by weight of salt, 12 parts by weight of white wine, 7 parts by weight of pepper, 3 parts by weight of monosodium glutamate, 3 parts by weight of minced ginger and 3 parts by weight of mashed garlic; weigh the above-mentioned salt, rock sugar, white wine, pepper, mon...

Embodiment 3

[0041] a. Preparation of fermentation bacteria: the fermentation bacteria include Lactobacillus pentosus, Pediococcus lactis, Inococcus, Staphylococcus xylosus, Staphylococcus mimetic, Micrococcus mutans and Staphylococcus epidermidis; cultivate the fermentation bacteria species respectively ,stand-by;

[0042] b. Preparation of raw materials: weigh lean meat and fat meat, then mince and mix the lean meat and fat meat to obtain raw meat for later use; prepare animal casings, clean them, drain the water, and wait for Use; The mass ratio of lean meat and fatty meat is 7:2;

[0043] c, preparation of ingredients: the ingredients are made of the following components by weight: 90 parts by weight of rock sugar, 25 parts by weight of salt, 13 parts by weight of white wine, 8 parts by weight of pepper, 3 parts by weight of monosodium glutamate, 3 parts by weight of minced ginger and 3 parts by weight of mashed garlic; weigh the above-mentioned salt, rock sugar, white wine, pepper, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com