Rolling control method based on ribbed bar rolling hole-type base circle radius

A control method and technology of ribbed steel bars, which are applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of complex pass design formula, high debugging work intensity, and change of rolled product specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

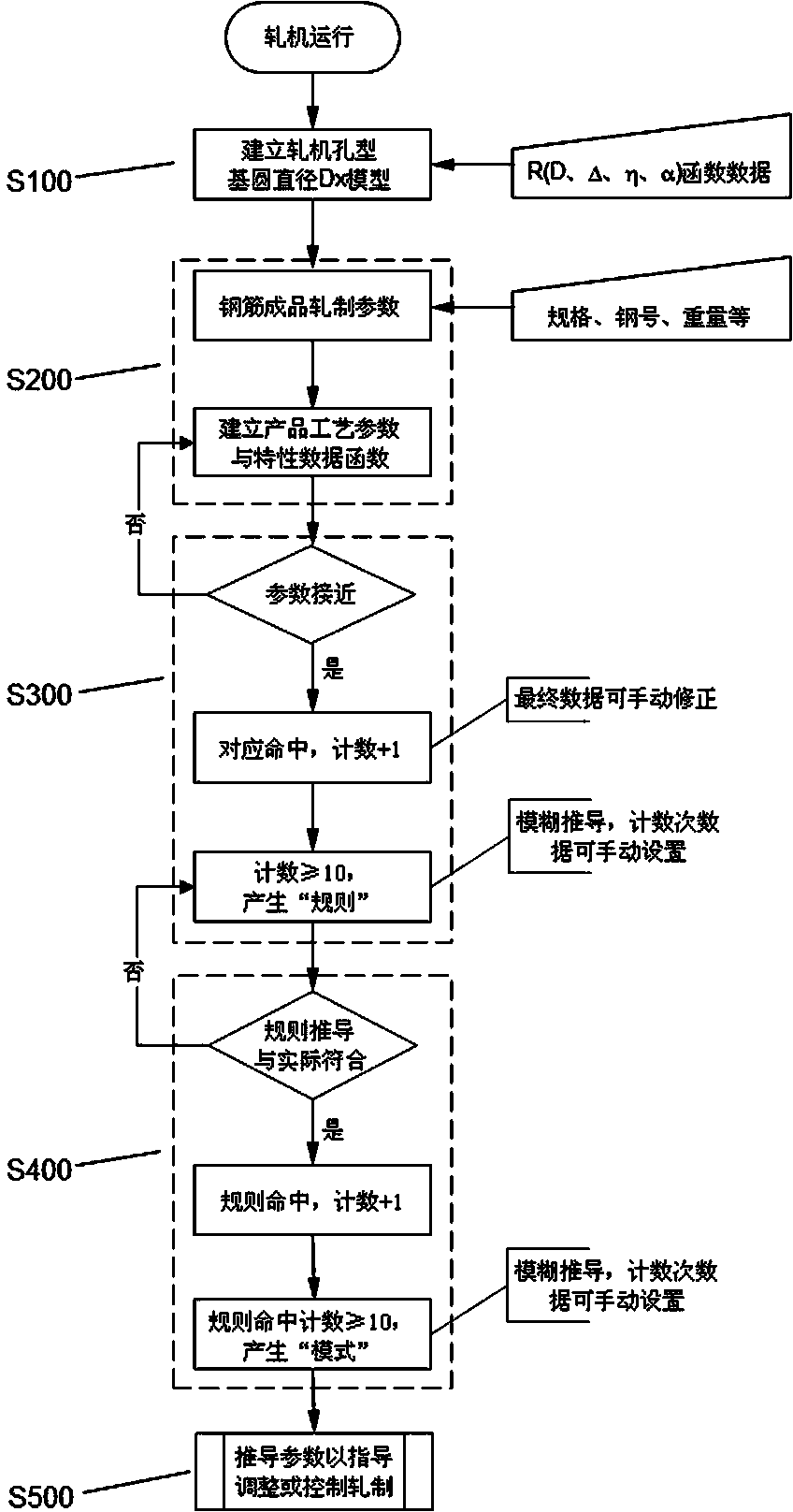

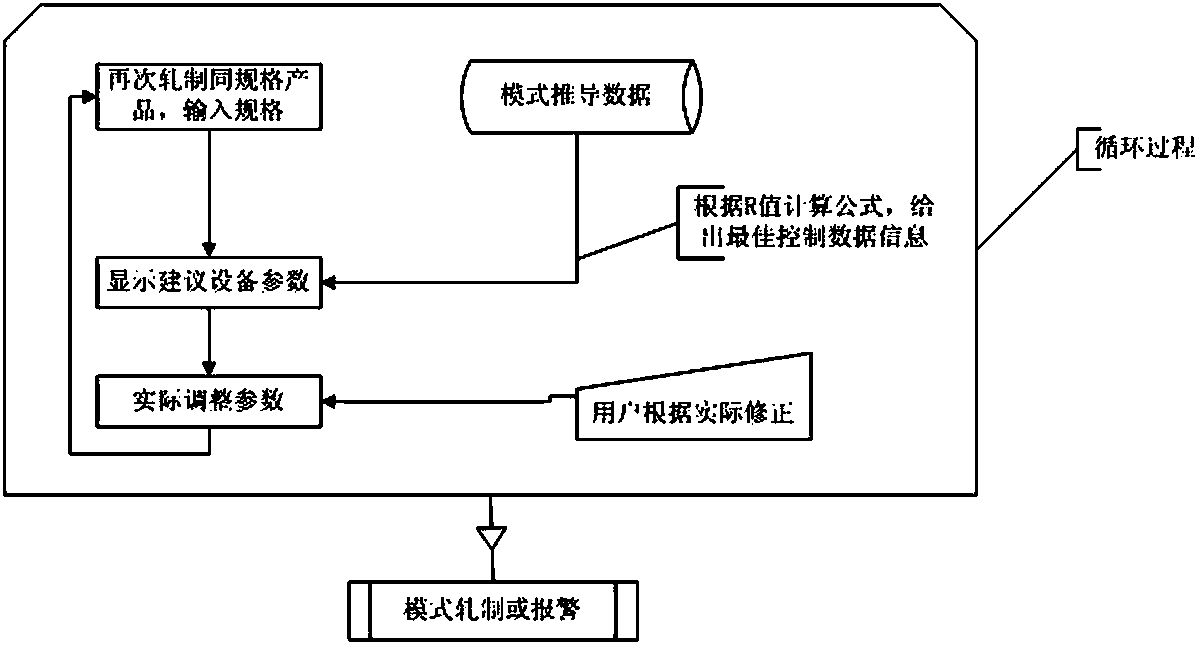

[0052] Such as figure 2 As shown, the control method is as follows:

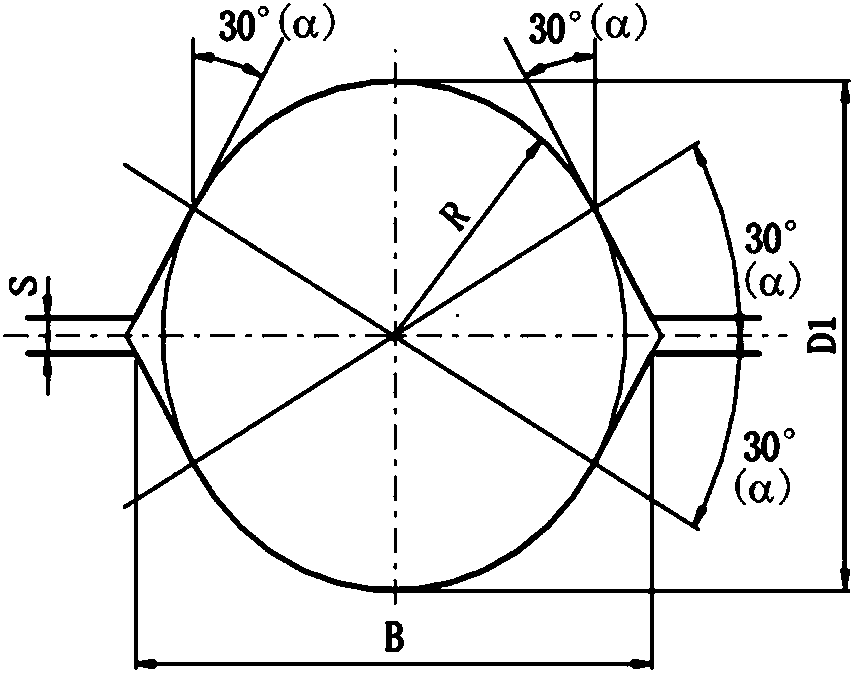

[0053] S100: According to the calculation formula for the pass design of the hot-rolled ribbed steel finishing mill (α = 30°):

[0054] R = [D – (0 → 0.1) Δ] * η / 2, establish the function mapping model of base circle radius R and cold state nominal diameter D, deviation Δ and thermal expansion coefficient η.

[0055] S200: Obtain rolling equipment parameters and product characteristic information from the rolling mill industrial control system at the production site based on the TCP / IP protocol, and establish a functional relationship f(d, δ) =g(R) between the deviation δ and the base circle radius R, and Store the D, Δ, η, d, δ values in the database.

[0056] S300: According to the functional relationship established in step (2), whenever there is a large deviation (δ) between the measured weight of the rolled piece and the standard weight, the system will make statistics on the historical data. If ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com