Device for closing in tightening nut and pipe joint module through oil press

A technology of tightening nuts and hydraulic presses, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large fluctuations in the size of the axial closing, unstable radial dimensions of the closing, and low pass rate of product tests. Uniform and stable test data, compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

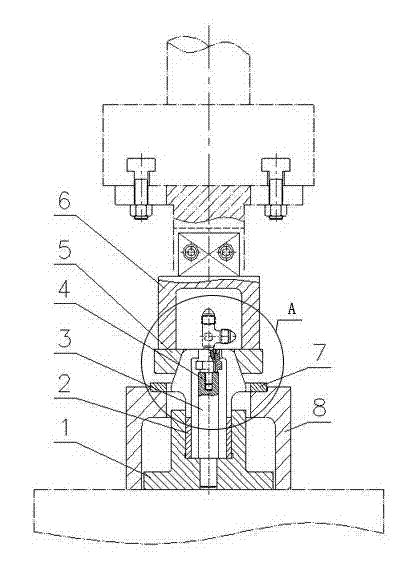

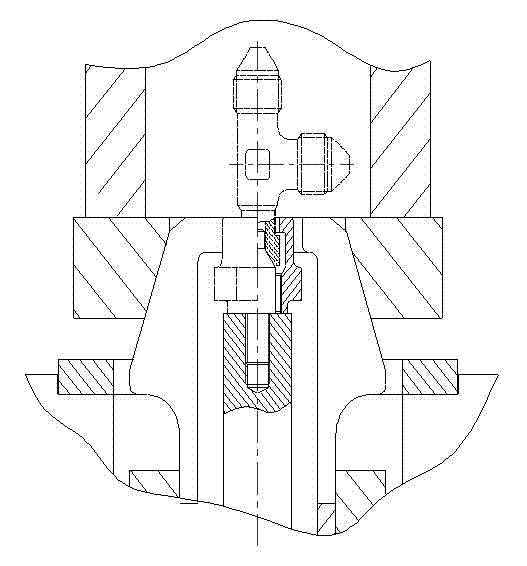

[0011] A device that uses a hydraulic press to close the tightening nut and pipe joint assembly, such as figure 1 and figure 2 As shown, it includes a base 1, a compression lower die 2, a core rod 3, a mold core 4, a compression upper die 5, a compression sleeve 6, an adjustment pad 7, and a limit seat 8; the base 1 is mounted on a hydraulic press On the workbench, screw the mold core 4 into the core rod 3, screw the thread to the bottom, put the assembly of the mold core 4 and the core rod 3 into the base 1, and put the compression lower mold 2 into the In the base 1, the compression lower die 2 and the base 1 are in a transitional fit, and the limiting seat 8 is attached figure 1 Place the middle position on the workbench of the hydraulic press, let the base 1 be in the limit seat 8, put the adjustment pad 7 into the shallow round table at the upper end of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com