Electrode assembly for cell welding

An electrode assembly and cell technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficult design, high technical requirements for welding protection plates, and easy damage to cells or protection plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments of the present invention.

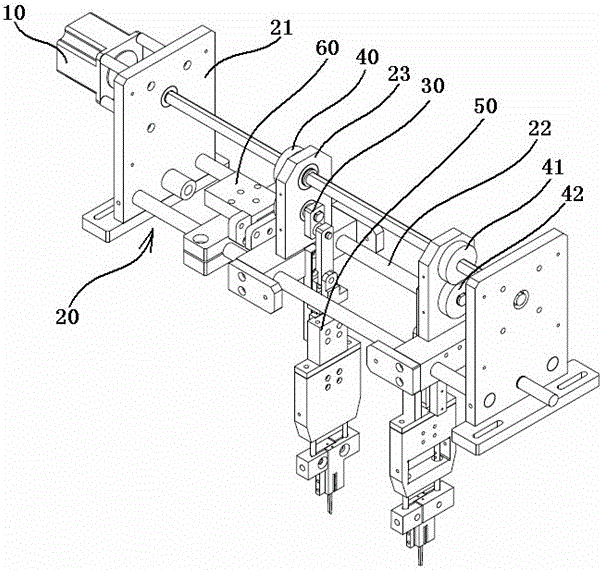

[0013] Please refer to the attached figure 1 : the electrode assembly includes a motor 10, a motor bracket 20, an eccentric wheel mechanism 30, a gear assembly 40 and a swing arm 50, the motor bracket 20 includes two end plates 21 and a suspension beam 22 between the end plates 21, and the motor 10 is installed on two On the end plate 21, the swing arm 50, the eccentric wheel mechanism 30 and the gear assembly 40 are all installed in the center of the suspension beam 22 in the middle; there is a pair of symmetrical inner support plates 23 in the center of the suspension beam 22, and the gear assembly 40 and the eccentric wheel mechanism 30 are installed in the center of the suspension beam 22. On the inner support plate 23 , the rotating shaft of the motor 10 is linked with the gear assembly 40 , the gear assembly 40 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com