Double color injection mold for front frame of computer

A two-color injection molding and front frame technology, which is applied in the field of mold structure, can solve the problems of low work efficiency, time-consuming and labor-intensive operation, poor hand feeling, etc., and achieve the effect of saving time and effort in operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

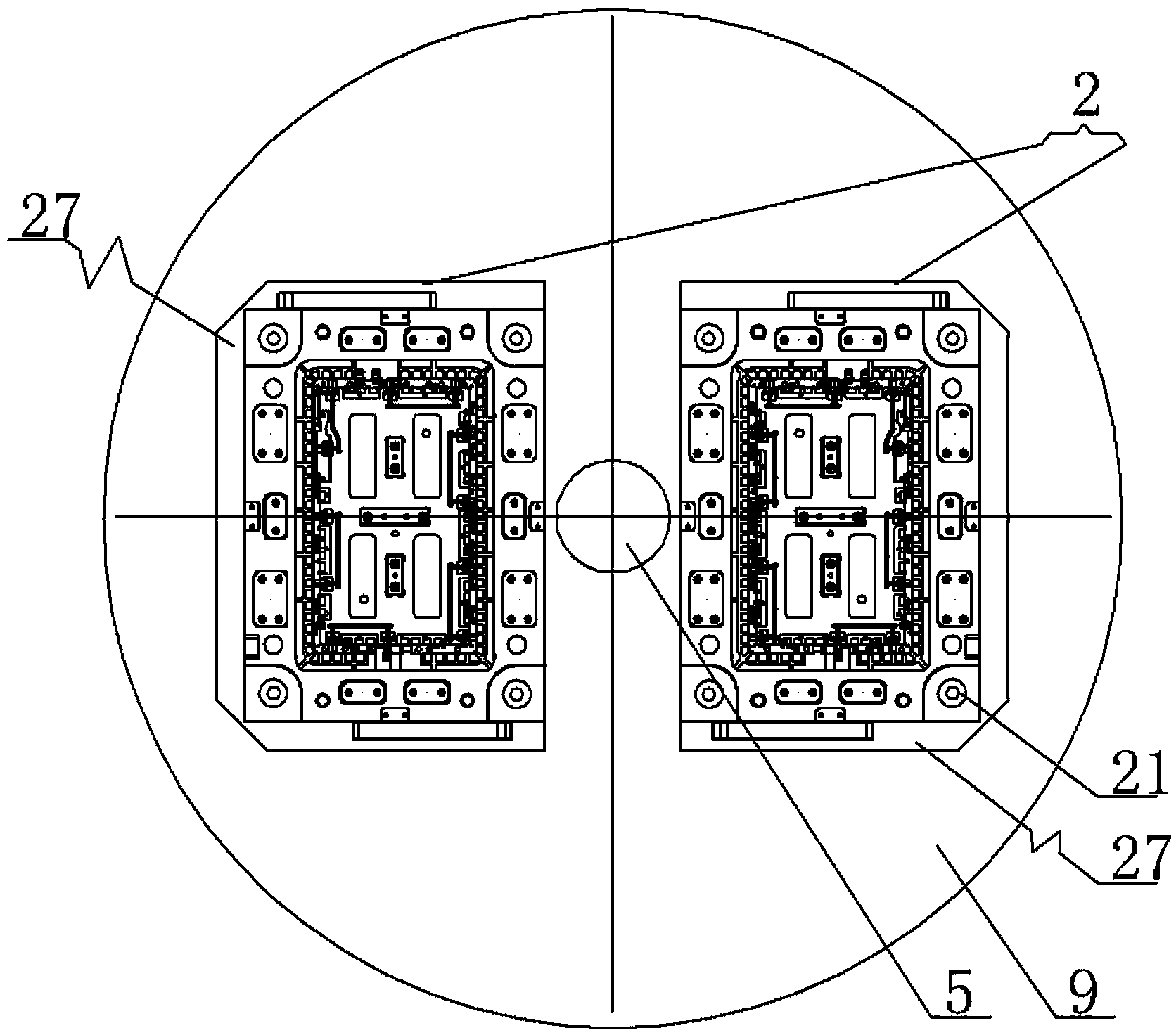

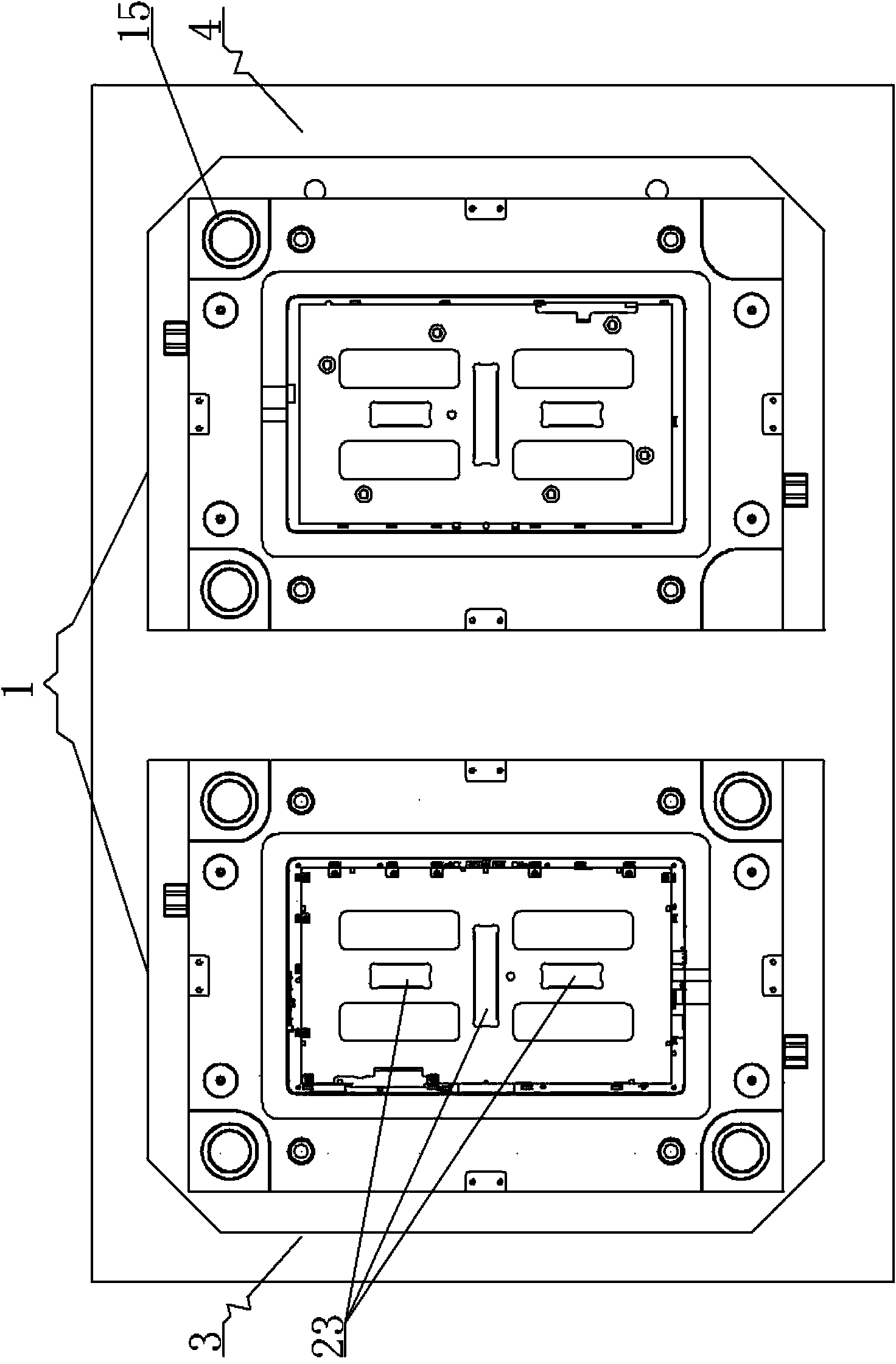

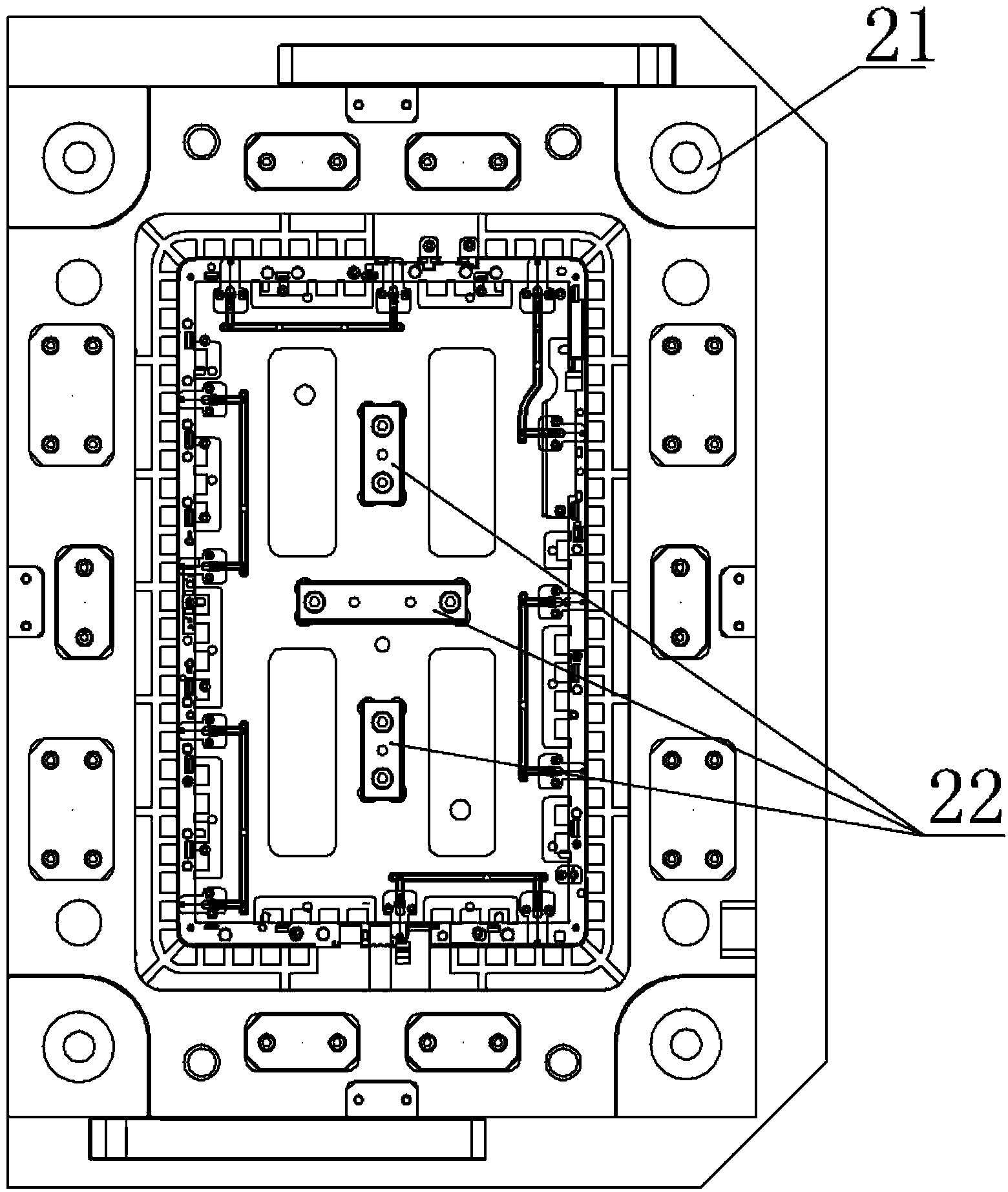

[0023] A two-color injection mold for the front frame of a computer, see Figure 1 to Figure 6 : It includes an upper female mold part 1 and a lower male mold part 2, the female mold part 1 and the male mold part 2 cooperate to form a cavity, and the female mold part 1 specifically includes the first female mold 3 and the second female mold 4 , the male mold part 2 can rotate axially around the rotating shaft 5, and the angle of rotation of the male mold part 2 ensures that the female mold 4 cooperates with the male mold part 2 and the hard rubber structure 6 to form a soft rubber cavity 7 for the second time. The master mold core 8 of the master mold 4 is convex downward corresponding to the edges of the hard rubber structure 6 and the soft rubber part, and the distance D of the downward convexity ensures that the hard rubber structure 6 is pre-compressed during the second injection molding.

[0024] The working principle is as follows: for the first time, the female mold 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com