Indium-magnesium composite sphere microcrystalline composite layer

A composite ball and composite layer technology, which is applied to layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of no indium-magnesium composite ball microcrystalline composite layer patent literature report, etc., and achieves suitable application cost, The effect of strong applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

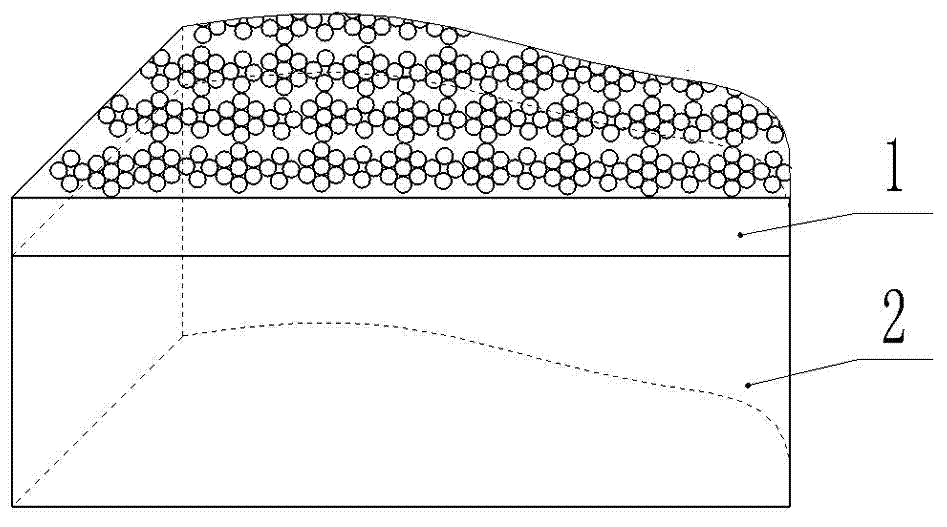

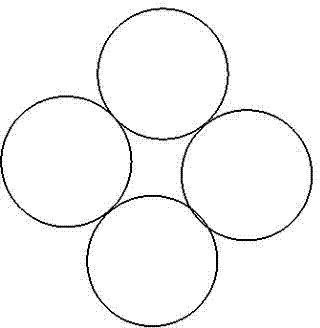

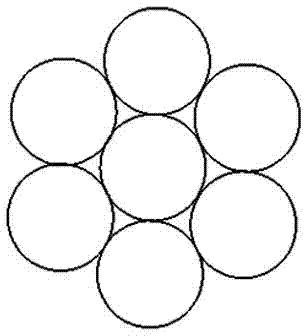

[0018] figure 1 It is the structural representation of the indium-magnesium composite ball microcrystalline composite layer of the embodiment 1 of the present invention; Fig. 2 (a) is that 4 spherical grains of the indium-magnesium composite spherical microcrystalline composite layer of the embodiment 1 of the present invention are closely connected to form a volume ratio Schematic diagram of the microcrystalline unit of the large indium-magnesium composite sphere, as figure 1 One of the indium-magnesium composite sphere microcrystalline units; Fig. 2 (b) is that more than 4 spherical crystal grains of the indium-magnesium composite sphere microcrystalline composite layer of the embodiment 1 of the present invention are closely connected to form larger indium-magnesium composite sphere microcrystals. The schematic diagram of the crystal unit is figure 1 One of the indium-magnesium composite spherical microcrystalline units, the more spherical grains there are, the larger the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com