Magnetic orientation pattern and preparation method thereof

A magnetic orientation and pattern technology, applied in the field of magnetic orientation pattern and its preparation, can solve the problems of large amount of pigment used, single overall optical effect of magnetic pigment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

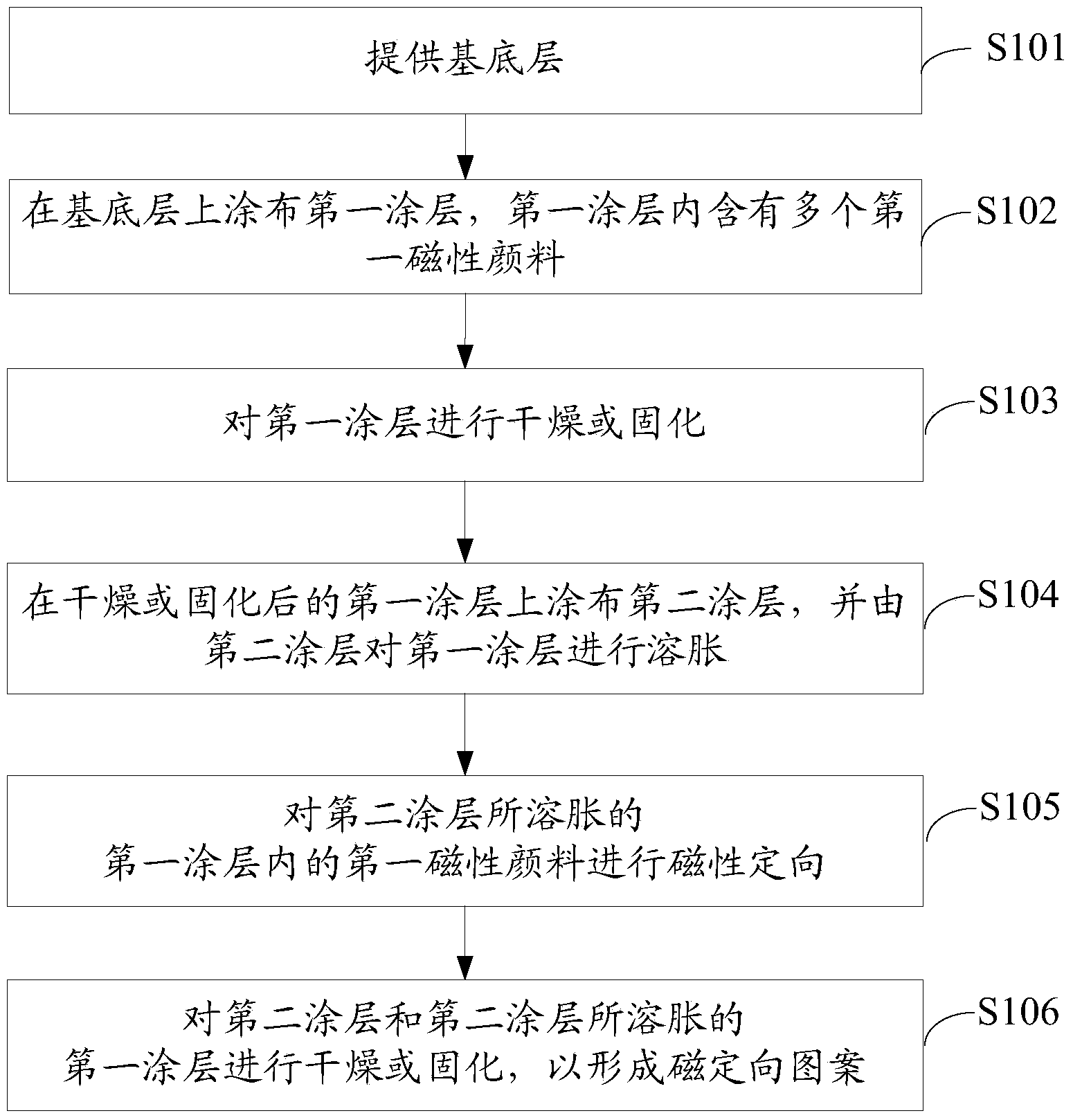

[0035] see figure 1 , figure 1 It is a flowchart of a method for preparing a magnetic alignment pattern provided by an embodiment of the present invention. The method for preparing a magnetic alignment pattern in this embodiment includes:

[0036] S101: providing a base layer;

[0037] Wherein, the substrate layer may be a fibrous substrate, such as paper or cardboard. Fiber-free porous substrates are also possible, such as plastic substrates with a porous surface, or even non-porous substrates with a textured or uneven surface structure. The base layer can be transparent, opaque or translucent. Colorless or pigmented substrates are also available as desired.

[0038] S102: Coating a first coating on the base layer, the first coating contains a plurality of first magnetic pigments;

[0039] The first coating can be applied according to any printing means known in the art, such as inkjet printing, offset printing, flexographic printing, gravure printing, stencil printing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com