Compression ratio adjustment method for diesel main engine of ship propulsion system

A propulsion system and adjustment method technology, applied in the direction of motor-driven engines, etc., can solve the problems of propulsion system optimization, fuel-saving effect is not obvious, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

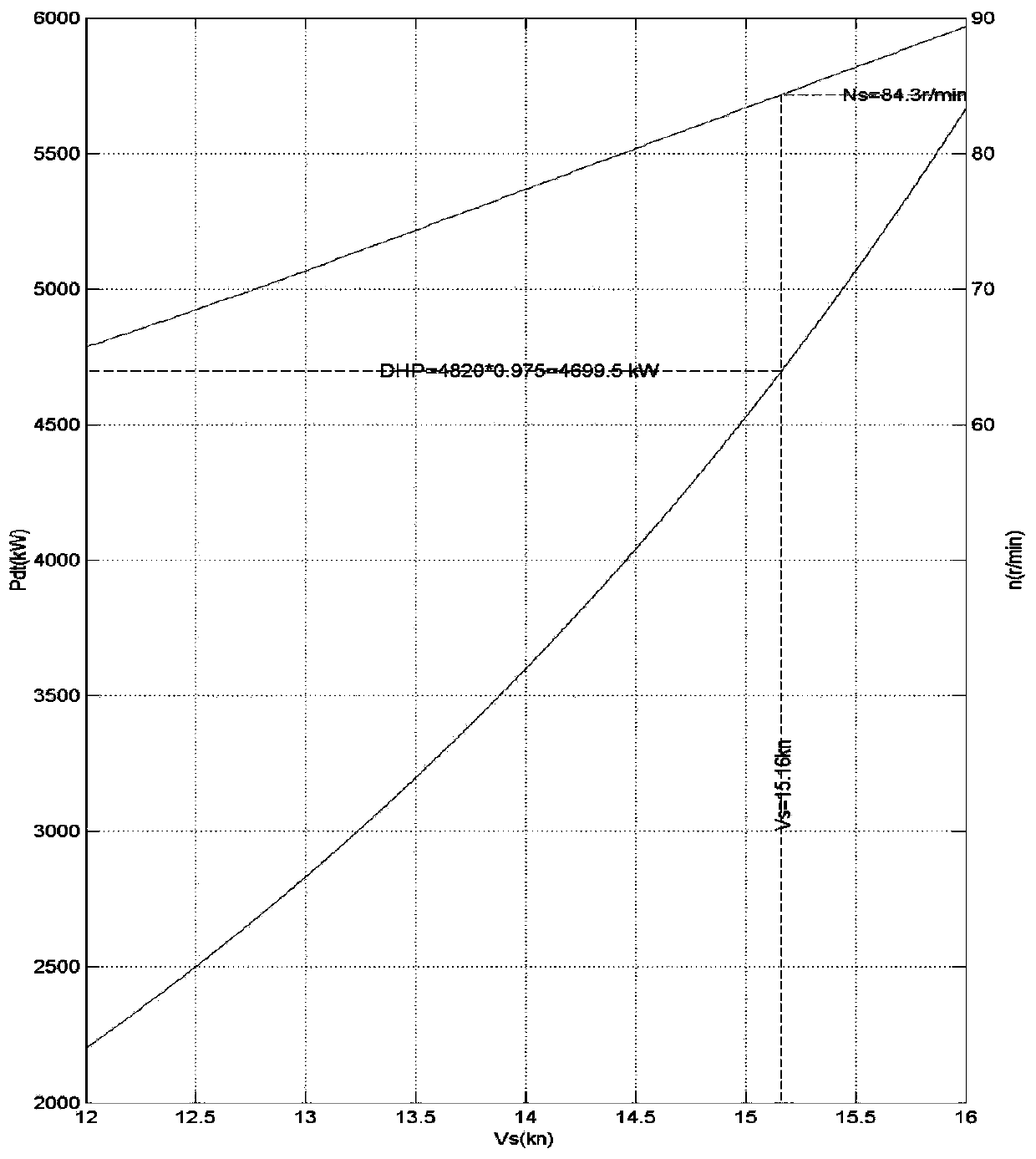

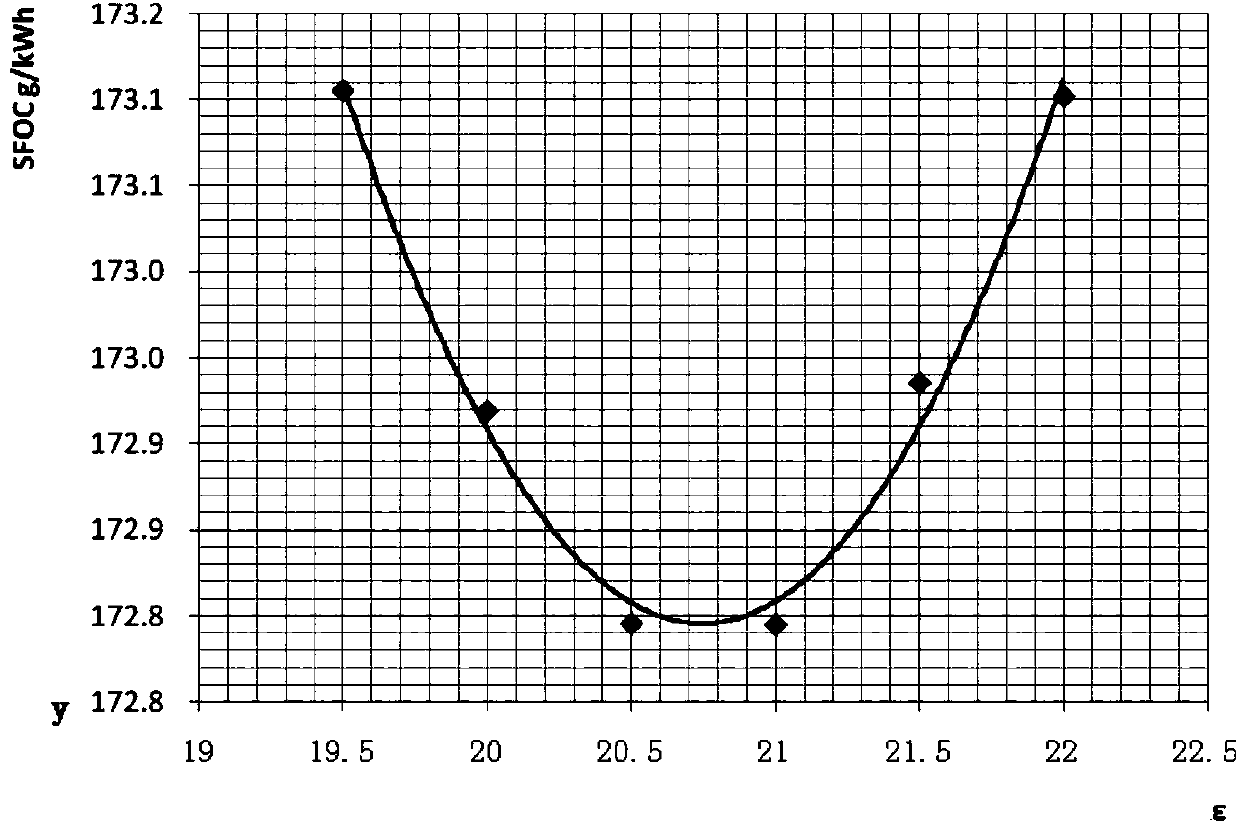

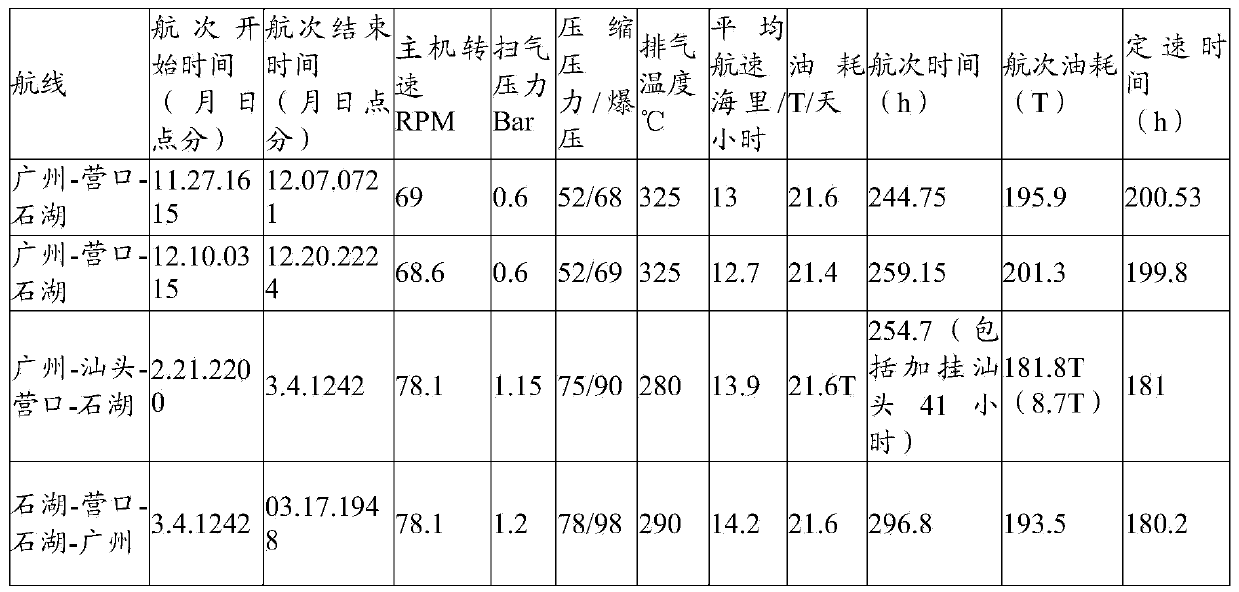

[0025] The ship propulsion system mainly includes a diesel main engine, shafting and propeller. Since the diesel main engine and the propeller are one of the main factors affecting the ship's operating speed, the present invention optimizes the diesel main engine and the propeller on the ship, so that the diesel main engine and the propeller of the adjusted parameters The redesigned new propeller achieves the purpose of high-efficiency operation at low speeds, and can also improve efficiency and greatly reduce fuel consumption at a lower cost. Because propeller and supercharger need to be redesigned and selected in the present invention, for the convenience of description, it is called the original propeller and the original supercharger before the transformation of the ship, and the new propeller and new superc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com