Automatic pasting double side tape device

A double-sided tape and automatic pasting technology, which is applied in the direction of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of low production efficiency, difficult to guarantee product quality, high labor cost, etc., and achieve the effect of stable tape pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

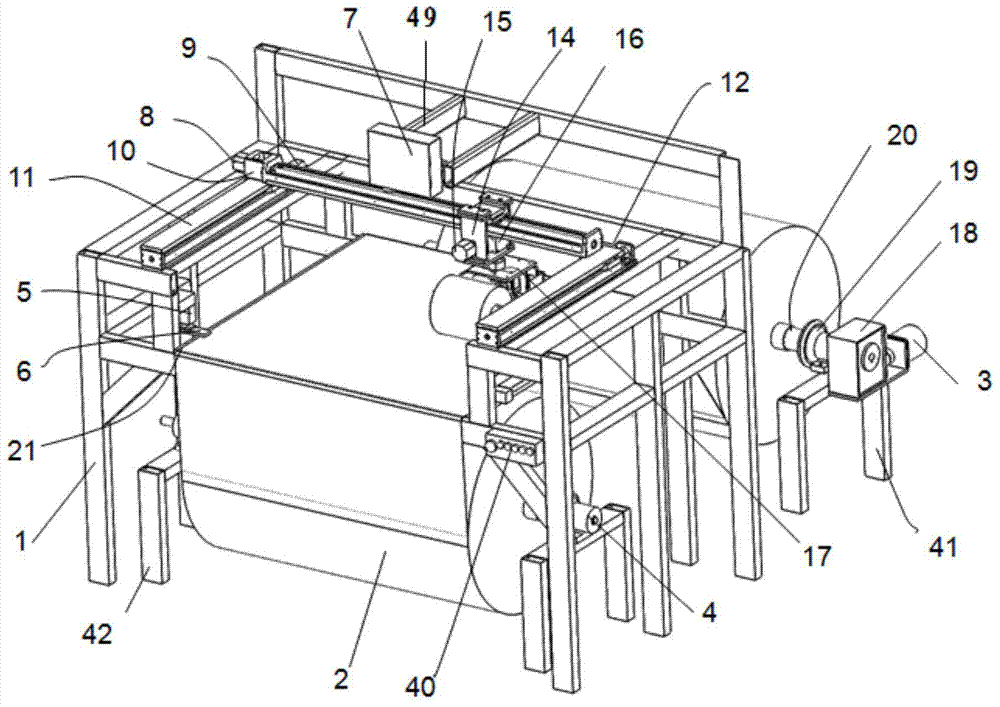

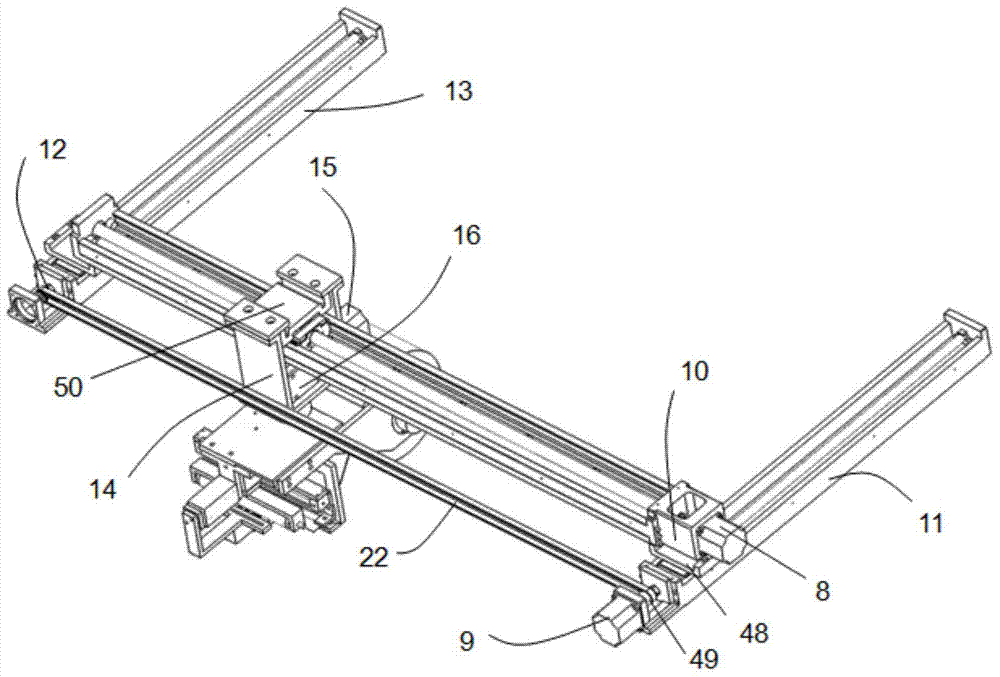

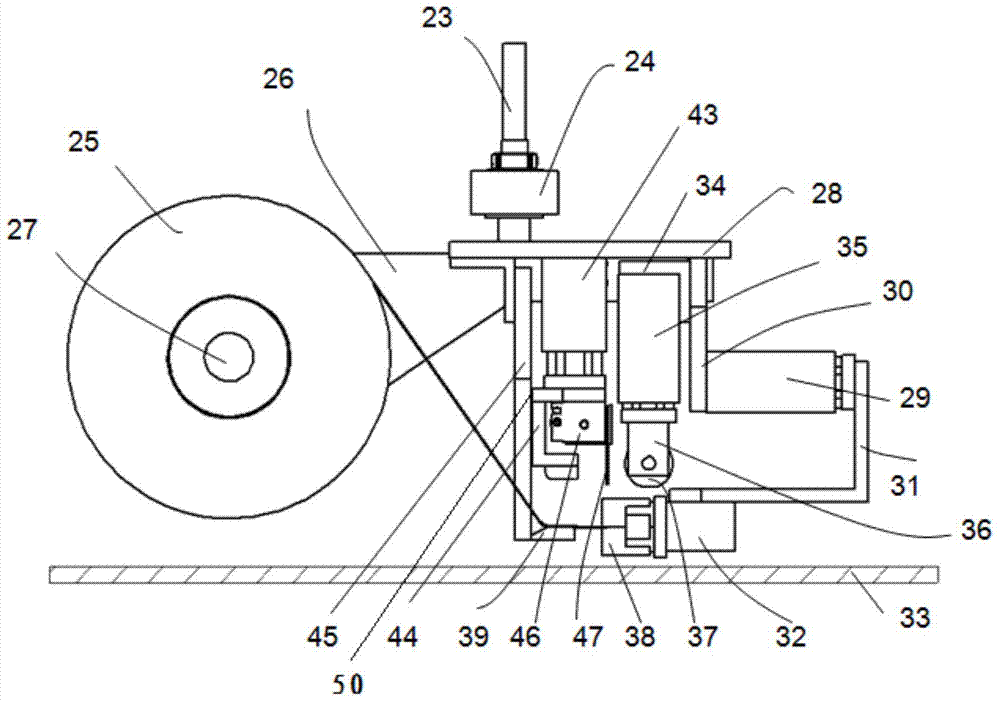

[0018] Such as Figures 1 to 3 As shown, the described equipment for automatically pasting double-sided adhesive tape is characterized in that it includes a workbench 1, and the left and right sides of the workbench 1 are respectively provided with a left single-arm motion mechanism composed of a ball screw nut pair and a linear motion guide rail pair. 11 and the right single-arm motion mechanism 13, the left single-arm motion mechanism 11 and the right single-arm motion mechanism 13 are respectively provided with a synchronous pulley 12 and are connected by a synchronous belt 22, wherein the synchronous pulley of a single-arm motion mechanism and the longitudinal motion Stepper motor 9 links to each other, and the nut slide plate 48 of left single-arm motion mechanism 11 and right single-arm motion mechanism 13 is equipped with the horizontal single-arm m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com