Heat and vibration combined aging device for residual stress homogenization

A residual stress and homogenization device technology, applied in the direction of improving process efficiency, can solve problems such as difficult residual stress comprehensive homogenization, and achieve the effect of simple structure and scientific conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

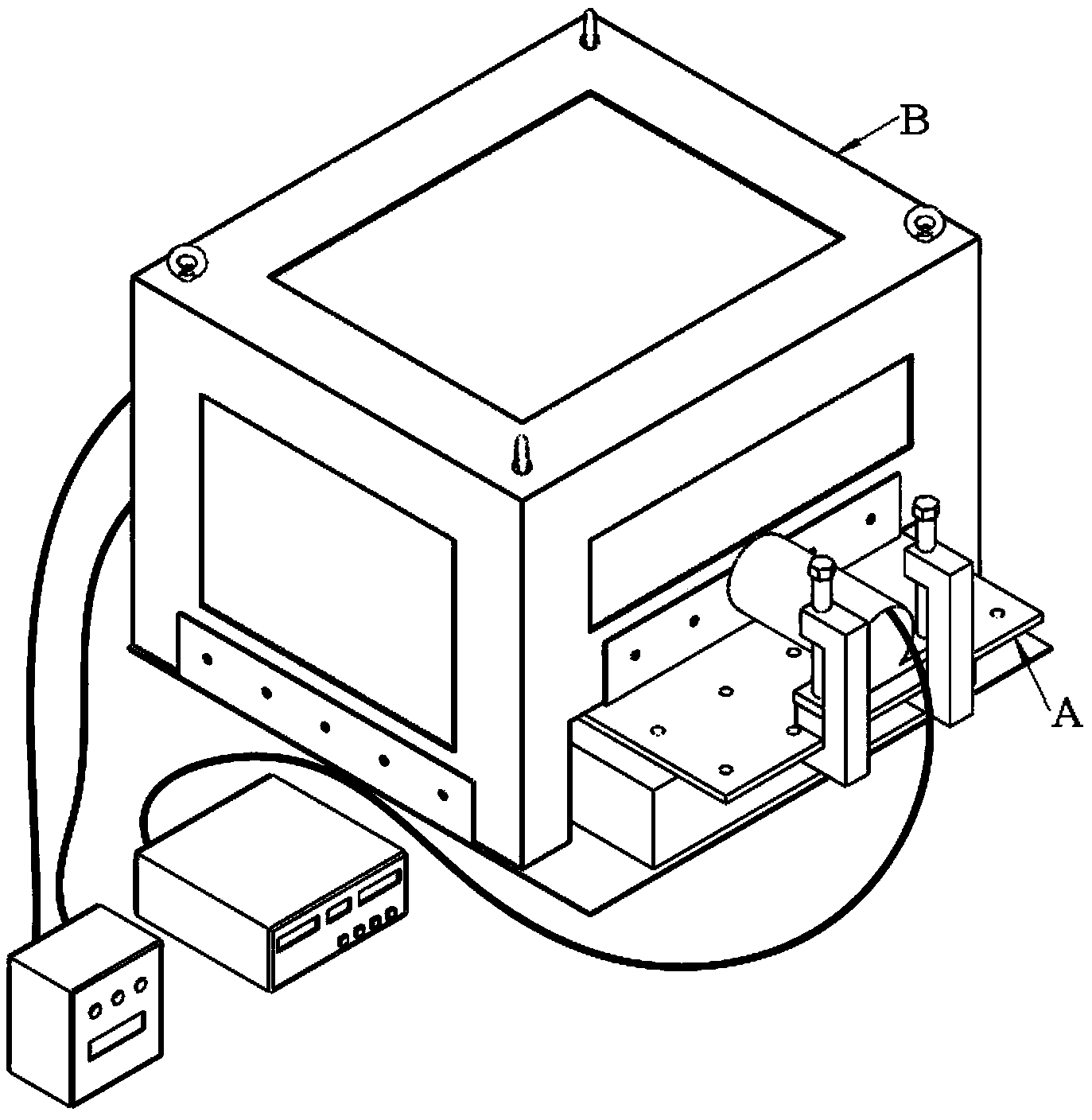

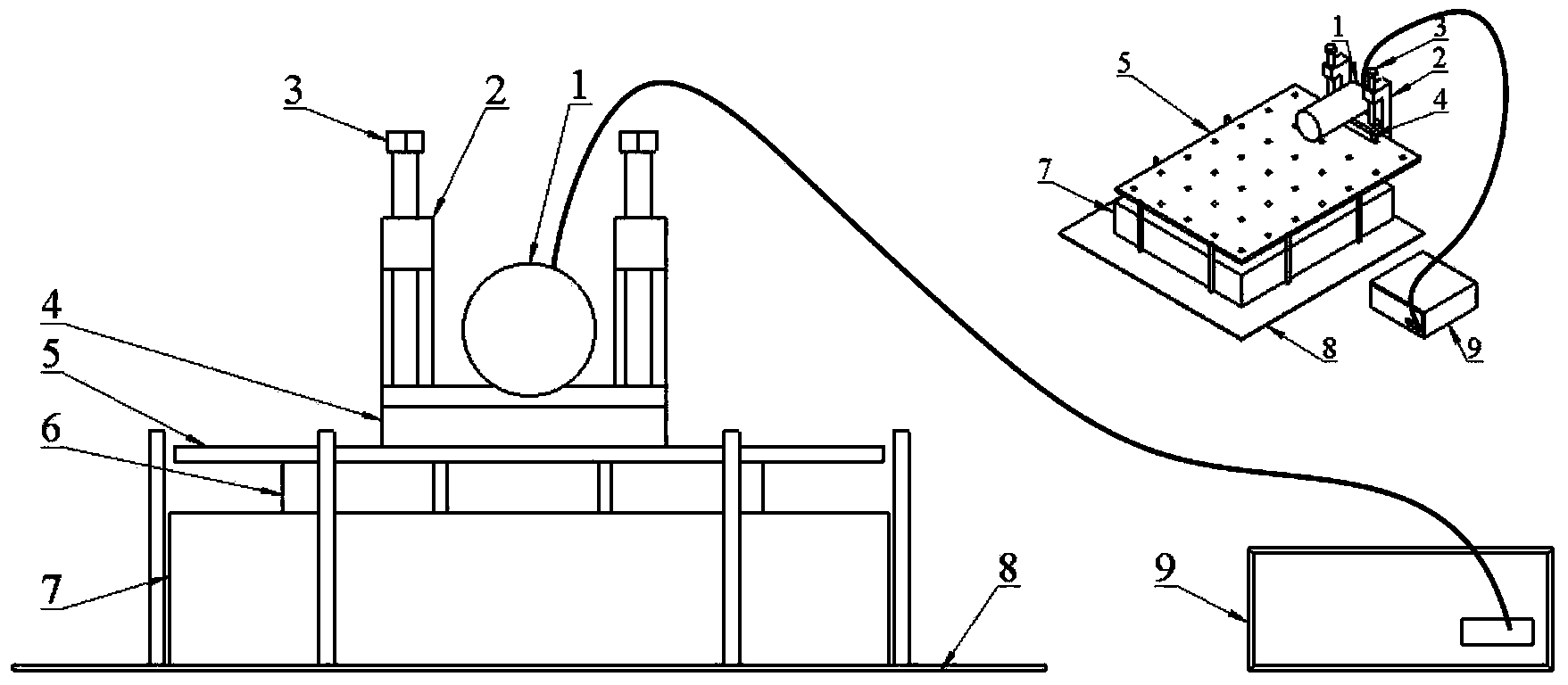

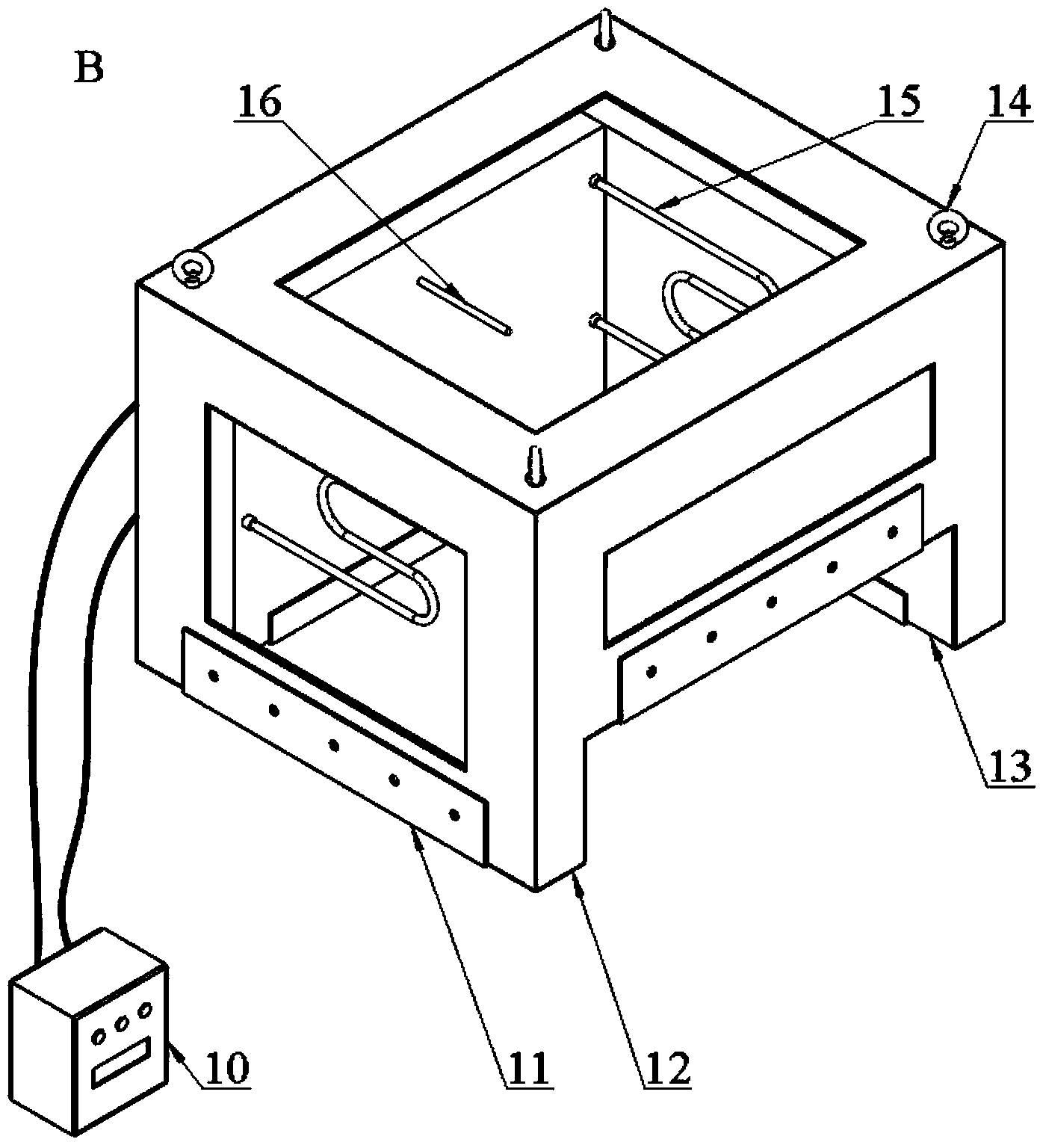

[0039] The present invention is a residual stress homogenization device of thermo-vibration composite aging, which is composed of a vibration aging system A and a thermal aging system B. The position connection relationship between them is: the bottom support 11, the outer cover 12 and the heat shield 13 of the thermal aging system B contain most of the vibration aging system A, and the bottom of the bottom support 11 and the bottom stop 8 of the vibration aging system A The upper surface is in contact, and the relative positions of the vibration aging system A and the thermal aging system B are positioned by adjusting the equal distance from the three bottom brackets 11 to the limit bars of the bottom stop 8. For the gap between the two system components, for thermal insulation , can be filled with insulation cotton or insulation b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com