Wrap-knitted hydrophobic polyester fabric imitating plant hairs

A warp knitting polyester and fluff technology, applied in the field of plant fluff bionic warp knitted fabrics, can solve problems such as rare reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

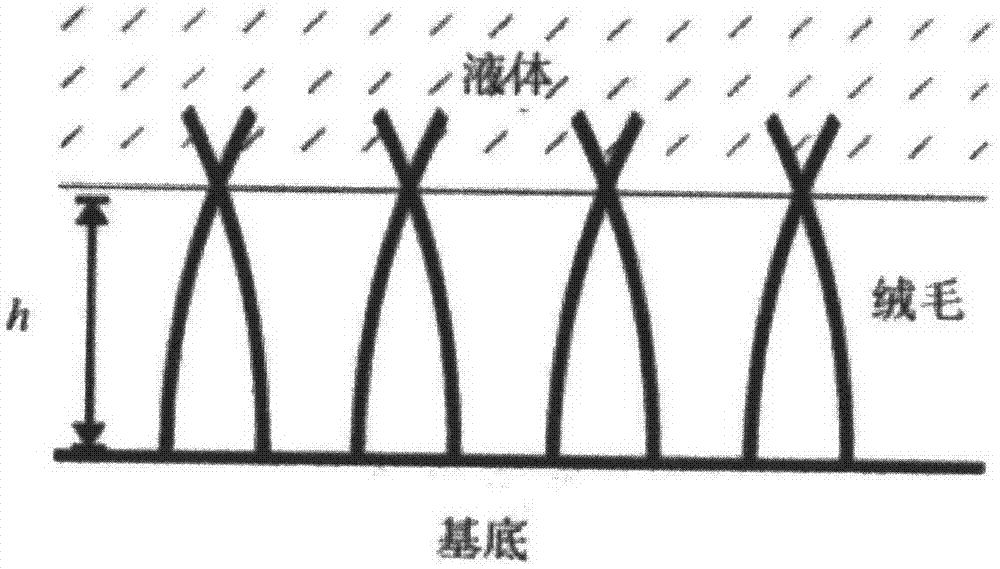

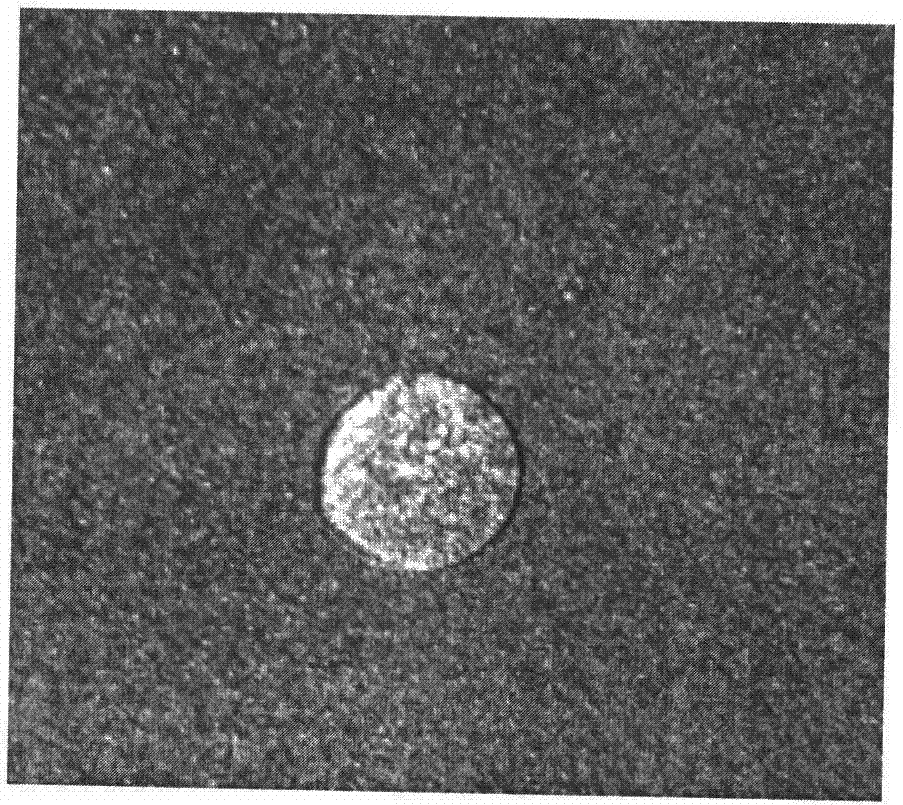

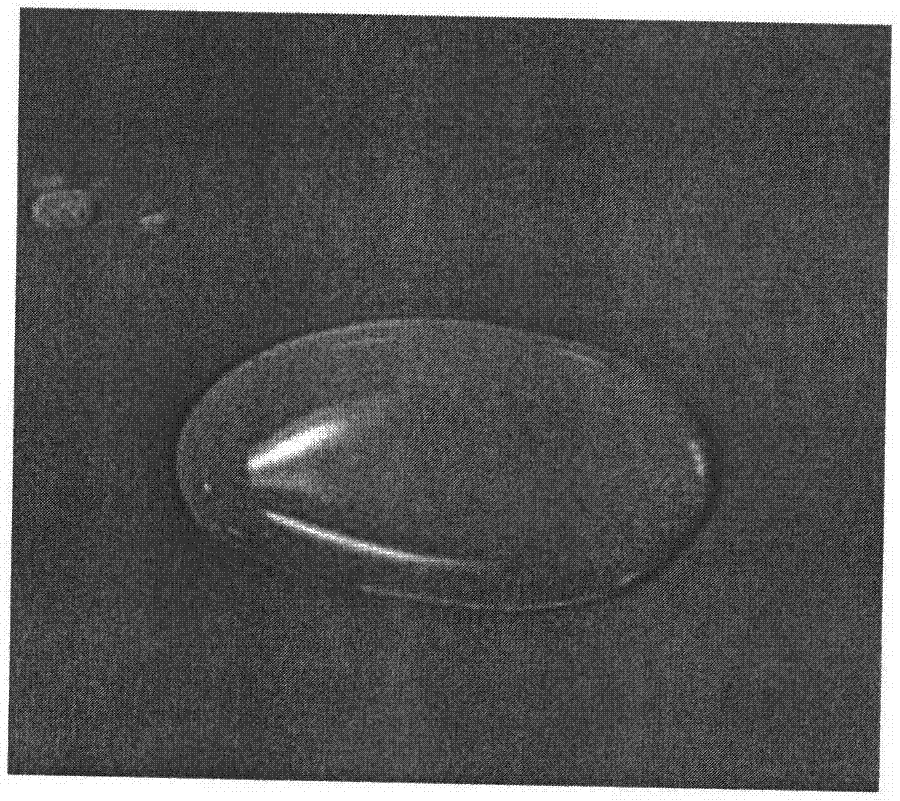

[0015] The polyester fiber is woven into a gray cloth on a warp knitting machine, wherein the yarn used for GB1 is sea-island fiber (sea phase water-soluble polyester, and the island phase is polyethylene phthalate); the gray cloth is shaped at 220°C, and then After the napping machine, the fabric is fluffed on one side; and then the shaping process is used to stabilize the size of the flannelette. The shaped flannelette is passed through a high-temperature water bath at 80°C for sea phase reduction, and then dried to obtain a fabric with nano-fluff. Put the previously treated flannelette into the dyeing vat, add degreaser, adjust the pH value and dye, then release the cloth, dehydrate and dry. Iron the functionally finished fabric at 180°C with an ironing roller, then trim off the fluff with inconsistent orientation to have a fluff height of 1 mm, and then finalize the finished product to obtain a fluffy fabric with soft hand feeling and hydrophobic function

Embodiment 2

[0017] The polyester fiber is woven into a gray cloth on a warp knitting machine, in which the yarn used for GB1 is sea-island fiber (sea-phase water-soluble polyester, and the island phase is polytrimethylene phthalate); the gray cloth is shaped at 210°C, and then brushed machine to fluff one side of the fabric; then use the setting process to stabilize the size of the flannelette. The shaped flannelette is passed through a high-temperature water bath at 70°C for sea phase reduction, and then dried to obtain a fabric with nano-fluff. Put the previously treated flannelette into the dyeing vat, add degreaser, adjust the pH value and dye, then release the cloth, dehydrate and dry. Iron the functionally finished fabric with an ironing roller at 170°C, then trim off the fluff with inconsistent orientation to have a fluff height of 1mm, and then finalize the finished product to obtain a fluffy fabric with soft hand feeling and hydrophobic function

Embodiment 3

[0019] The polyester fiber is woven into a gray cloth on a warp knitting machine, wherein the yarn used for GB1 is sea-island fiber (sea phase water-soluble polyester, and the island phase is polybutylene phthalate); the gray cloth is shaped at 195°C, and then After the napping machine, the fabric is fluffed on one side; and then the shaping process is used to stabilize the size of the flannelette. The shaped flannelette is passed through a high-temperature water bath at 65°C for sea phase reduction, and then dried to obtain a fabric with nano-fluff. Put the previously treated flannelette into the dyeing vat, add degreaser, adjust the pH value and dye, then release the cloth, dehydrate and dry. Iron the functionally finished fabric with an ironing roller at 155°C, trim off the fluff with inconsistent orientation to make it have a fluff height of 1mm, and then finalize the finished product to obtain a fluffy fabric with soft hand feeling and hydrophobic function

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com