Shoe making cloth processing device

A technology for processing devices and fabrics, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, and fabric surface trimming, etc. It can solve problems such as unusable fabrics and fabrics contaminated with dust, and achieve the effects of reducing failure rates, high product quality, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

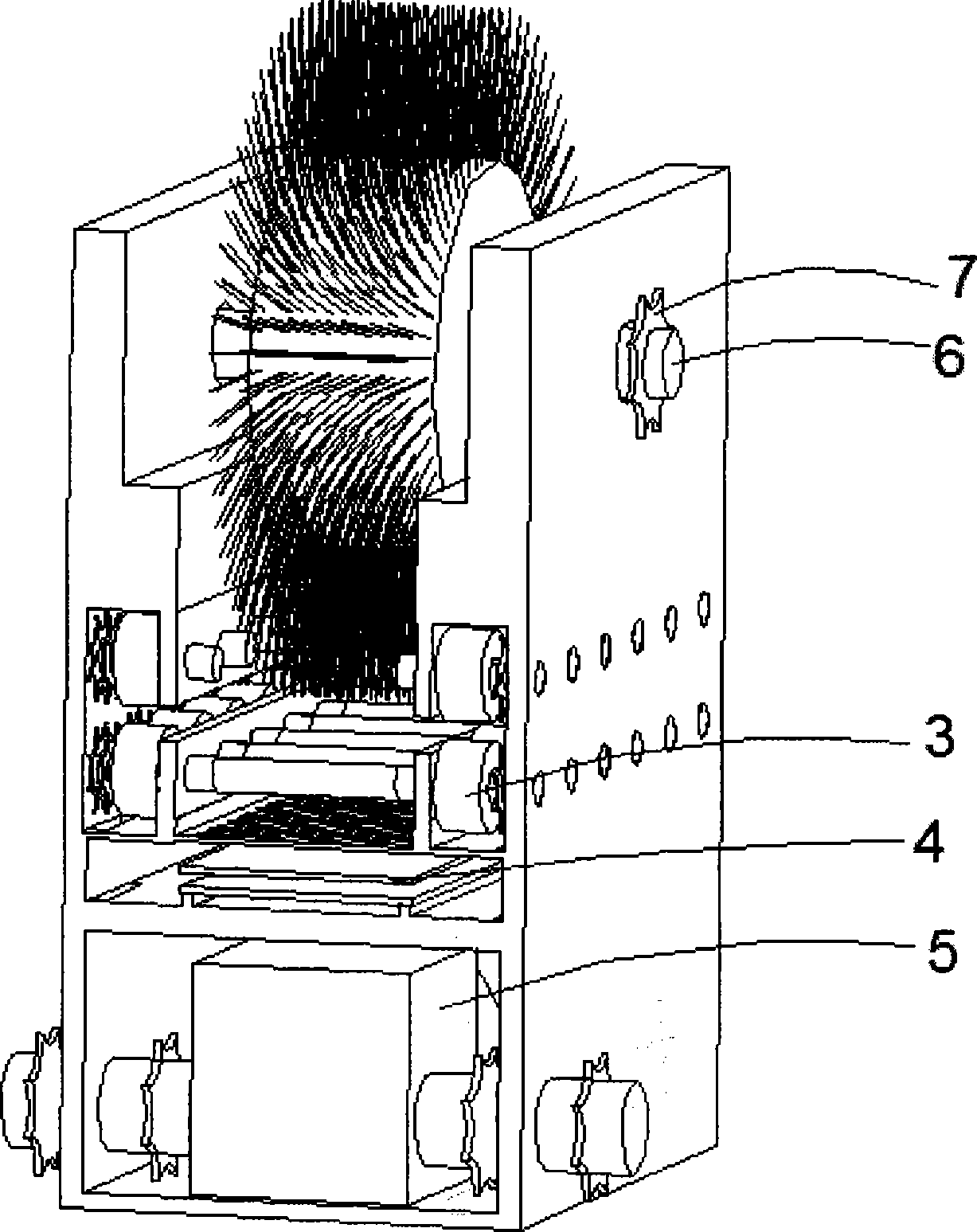

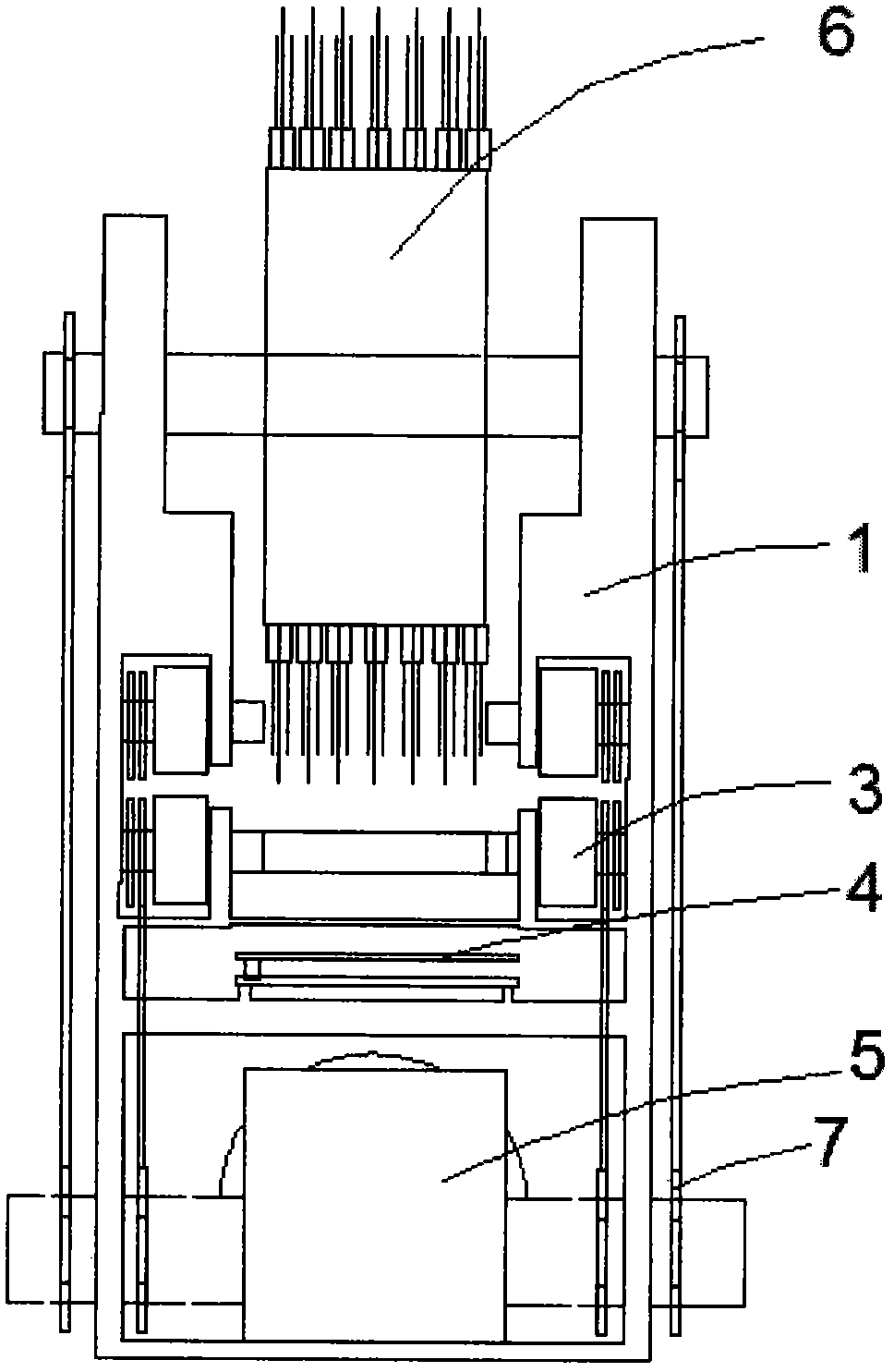

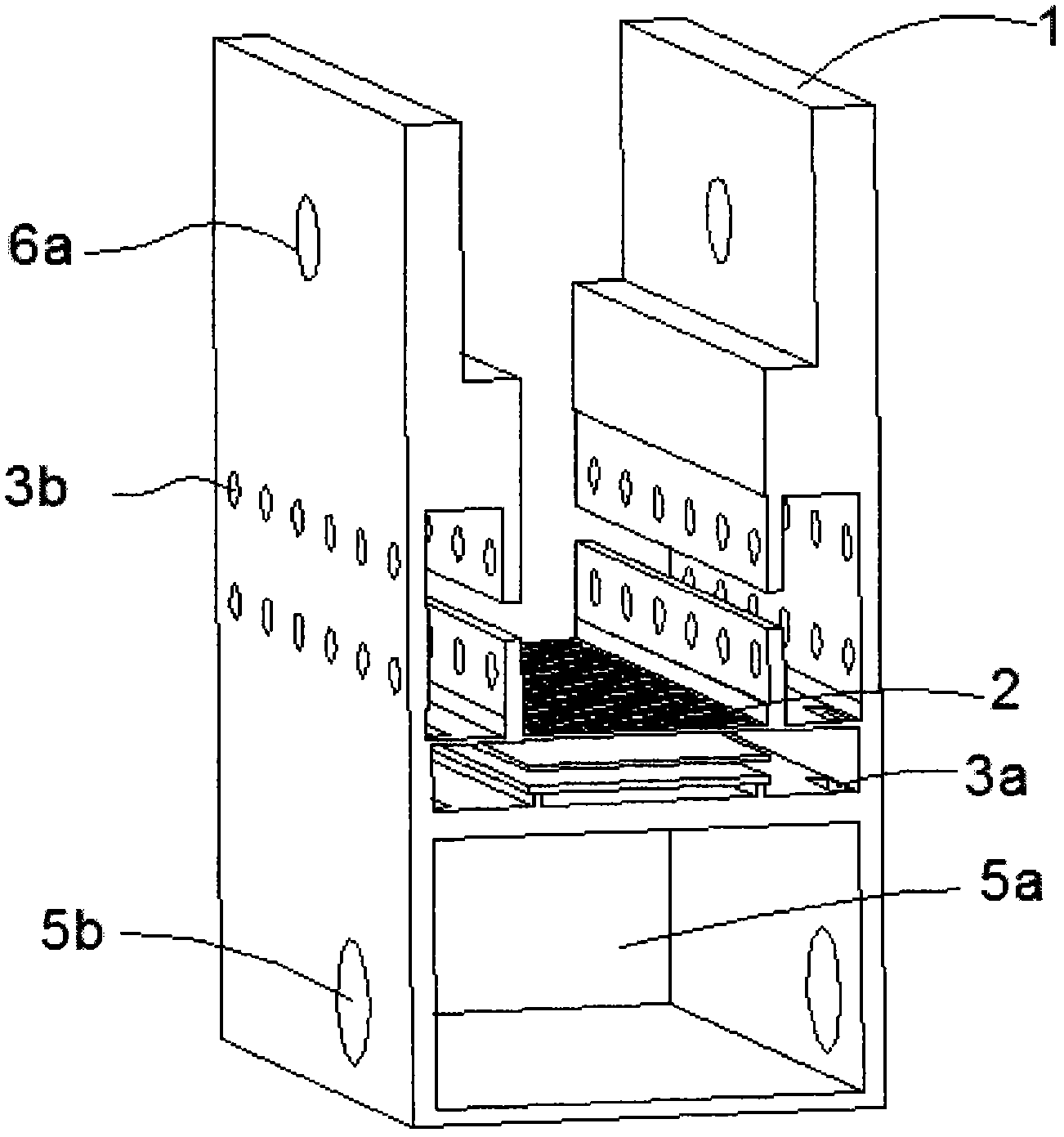

[0019] This specific embodiment adopts the following technical solutions: a cloth processing device for shoemaking includes a frame, a power input unit, and a conveying processing unit; the frame 1 is configured with a chain opening 3a for allowing the chain to pass through. The accommodating cavity 5a for accommodating the motor and its double-output reduction box, the first shaft hole 5b for fixing the output shaft of the double-output reduction box, the second shaft hole 3b for fixing the roller, and the third hole for fixing the rotating brush shaft hole 6a;

[0020] The power input unit includes: a motor (not shown in the figure), a double output reduction box 5;

[0021] The conveying processing unit includes: roller 3, heating wire 4, rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com