Method for two-stage fairing-mounted rocket body free boundary implementation and fairing fixed-end boundary implementation in vibration tower

A secondary technology with a cover and a fixed support boundary, which is applied to the testing of measuring devices, instruments, machines/structural components, etc., can solve the problems of difficult design of fixed support tooling, achieve short test preparation periods, reduce test risks, The effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

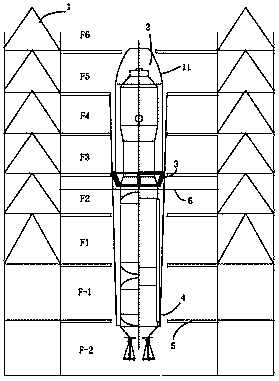

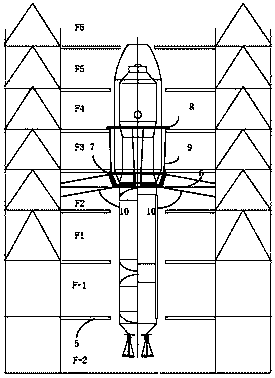

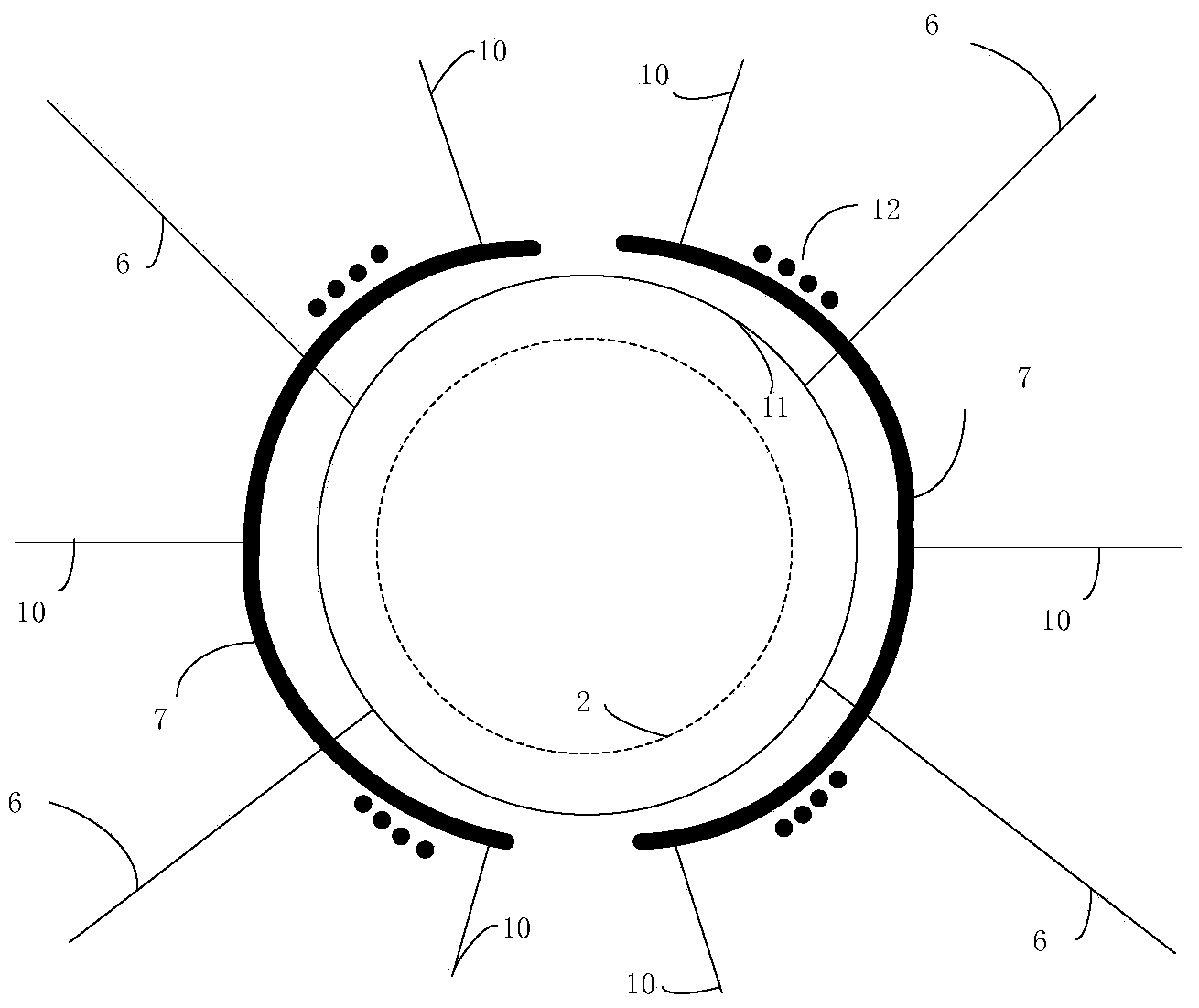

[0061] Step 1: Fix the tooling, this step is common knowledge, as attached Figure 4 shown;

[0062] Step 1.1: According to the distribution position and size of the protrusions at the docking surface of the fairing 11, the form of the docking surface and the distribution size of the docking holes, determine the circumference of the punching hole 15 and the position of the through hole 16 for avoiding the structural interference of the docking surface;

[0063] Step 1.2: According to the space size required for assembly and docking operation of the fairing 11 test site, determine the size of the through hole 16 for avoiding structural interference of the docking surface to be 370mm×350mm;

[0064] Step 1.3: Determine the inner diameter 13 of the tooling and the outer diameter 14 of the tooling according to the distribution of the ground rails on the ground of the second floor F-2 in the vibrating tower and the distance between the ground rails of 1m; in order to maximize the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com