Inner-posted poster and manufacturing method thereof

A production method and a technology of advertising pictures, which are applied in the field of advertising pictures, can solve the problems of high difficulty in construction, inability to paste, and influence on pasting, and achieve the effects of safe and convenient pasting and replacement, easy production, and firm pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

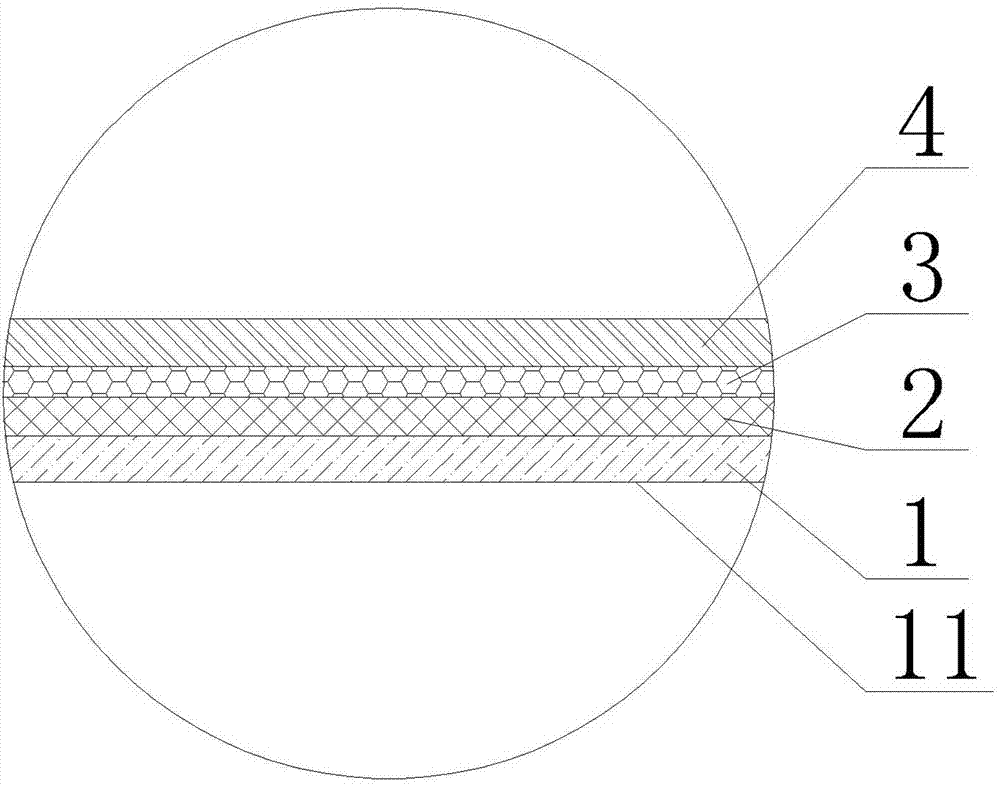

[0035] Such as figure 2 Shown, the making method of interior poster of the present invention comprises the steps:

[0036] A, make the color background layer 4;

[0037] B. Coating the self-adhesive layer 3 on the color-developing background layer 4;

[0038] C, on the transparent film 1, make the pattern layer 2 with the method of inkjet printing or silk screen printing or printing or hot stamping;

[0039] D. Paste the color-developing background layer 4 on the surface of the transparent film 1 provided with the pattern layer 2 through the self-adhesive layer 3, and complete the production of the inner poster.

Embodiment 2

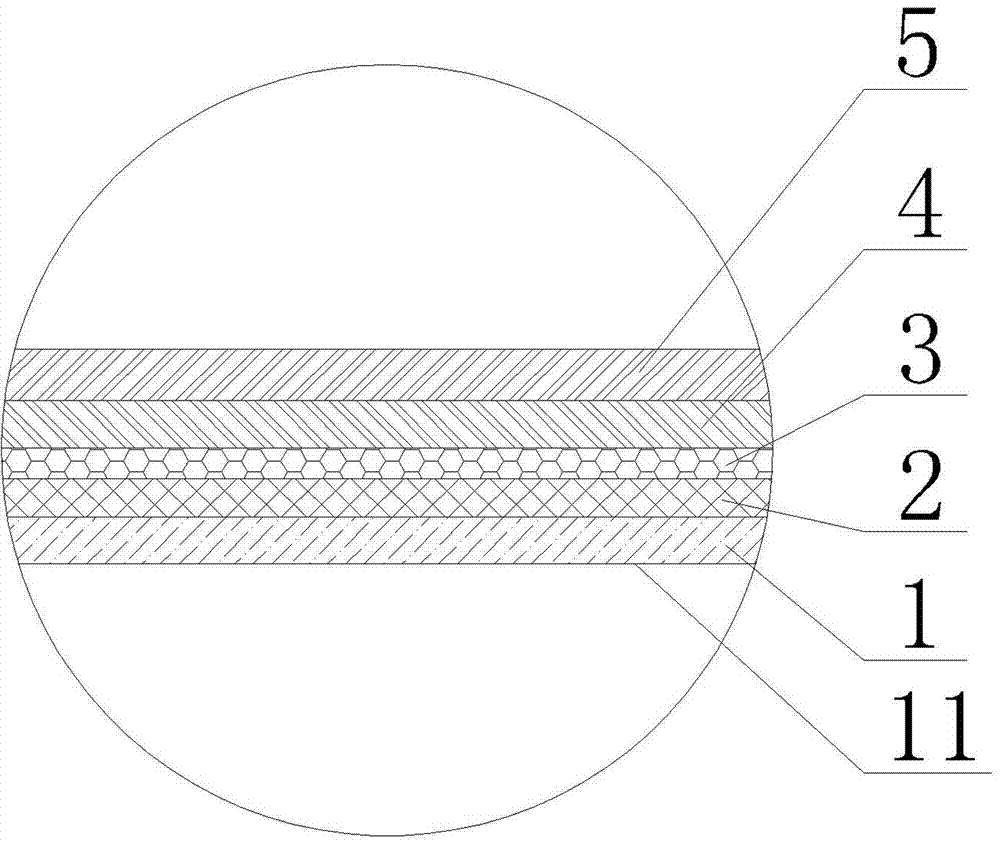

[0041] Such as image 3 Shown, the making method of interior poster of the present invention comprises the steps:

[0042] A, make the color background layer 4;

[0043] B, a light-shielding layer 5 is set on one side of the color-developing background layer 4;

[0044] C, coating the self-adhesive layer 3 on the other side of the color-developing background layer 4;

[0045] D, make the pattern layer 2 on the transparent film 1 with the method of inkjet printing or silk screen printing or printing or hot stamping;

[0046] E. Paste the color-developing background layer 4 on the surface of the transparent film 1 provided with the pattern layer 2 through the self-adhesive layer 3, and complete the production of the inner poster.

Embodiment 3

[0048] Such as Figure 4 Shown, the making method of interior poster of the present invention comprises the steps:

[0049] A, make the color background layer 4;

[0050] B, a light-shielding layer 5 is set on one side of the color-developing background layer 4;

[0051] C, the picture printing layer 6 is set on the light-shielding layer 5, and the picture is printed on the picture printing layer 6;

[0052] D, coating the self-adhesive layer 3 on the other side of the color-developing background layer 4;

[0053] E, make the pattern layer 2 on the transparent film 1 with the method of inkjet printing or silk screen printing or printing or hot stamping;

[0054] F. Paste the color-developing background layer 4 on the surface of the transparent film 1 provided with the pattern layer 2 through the self-adhesive layer 3, and complete the production of the inner poster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com