Plate cylinder for a printing press, comprising a clamping device

A technology of printing plate cylinder and clamping device, which is applied to general parts of printing machinery, printing presses, printing and other directions, can solve problems such as inability to achieve precision, and achieve the effect of improving precision and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

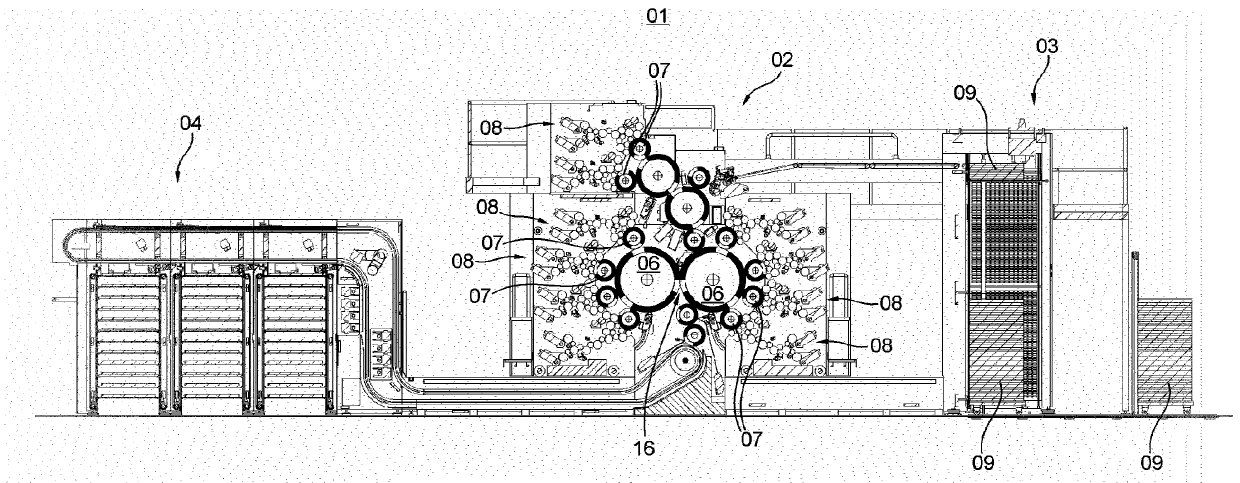

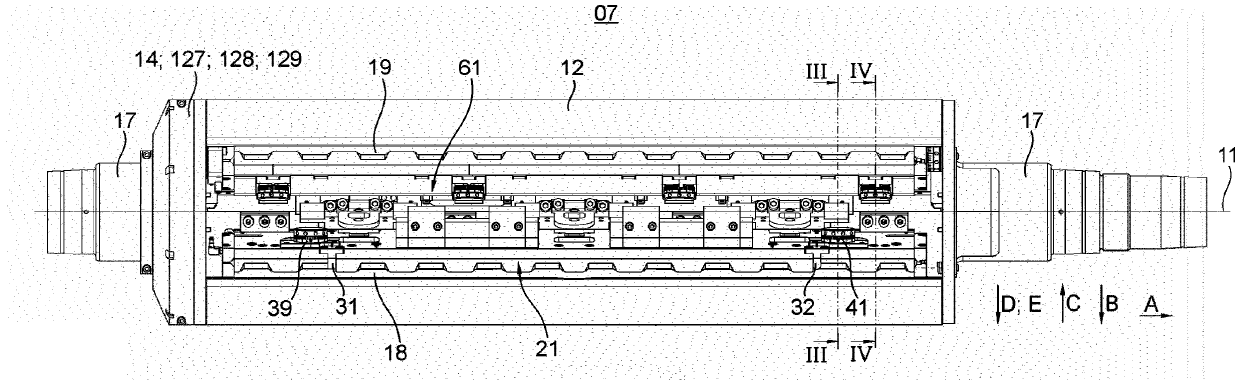

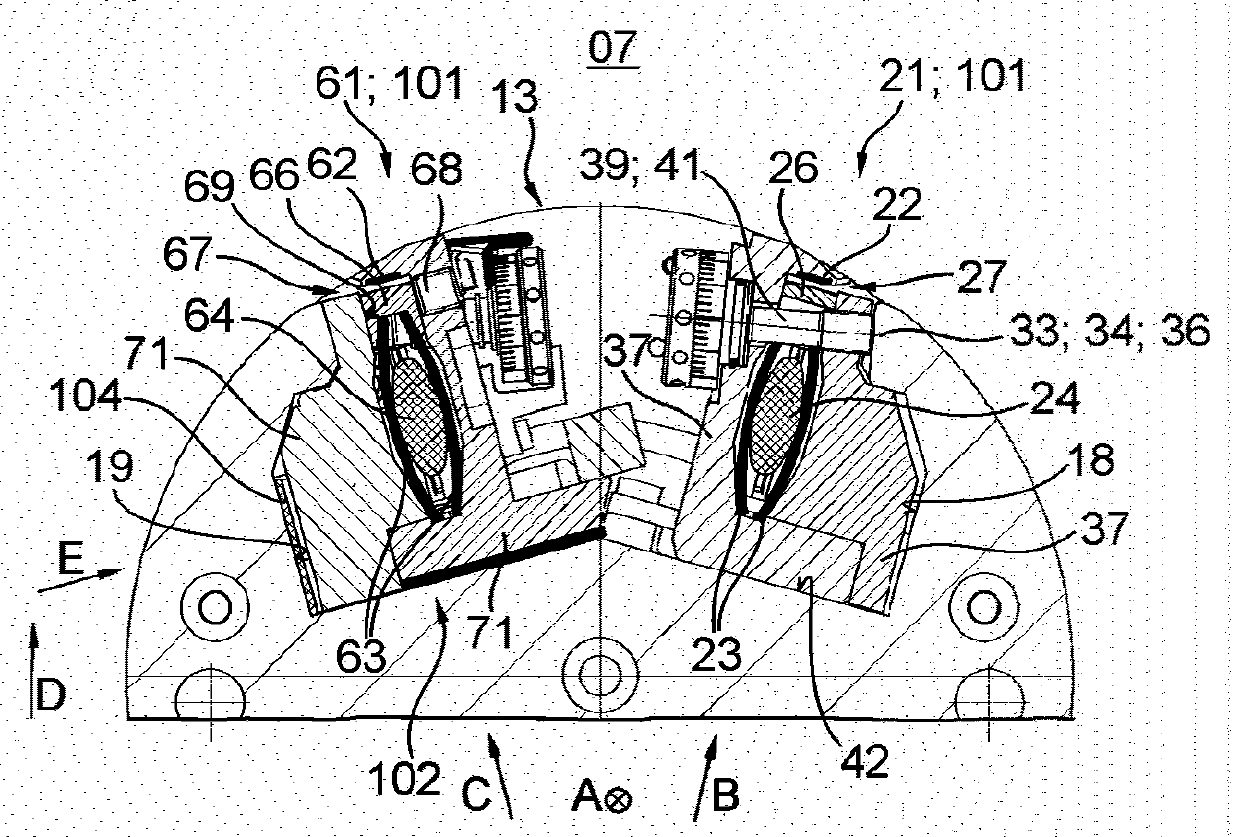

[0102] A printing press 01 designed as a rotary printing press 01 , for example as a sheet-fed rotary printing press 01 , is described below. The printing machine 01 is, for example, the printing machine 01 used for currency printing. The printing press 01 is designed as a printing press 01 for printing a printing material 09 , preferably in sheet-fed form, ie a sheet-fed printing press 01 . The printing press 01 has at least one printing unit 02 with at least one printing unit 08 and at least one inking unit, wherein the at least one printing unit 08 has at least one plate cylinder 07 . The at least one plate cylinder 07 is preferably designed as at least one plate cylinder 07 . Preferably, a plurality of printing units 08 and a plurality of inking units are arranged in the at least one printing unit 02 in order to print different inks on the same printing material 09 in the same production, eg depending on the number of the inking units. In one embodiment, a plurality of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com