Rolling mill with speed measuring and pressure regulating structure

A pressure regulating and rolling mill technology, which is applied in the field of rolling mills with a speed measuring and pressure regulating structure, can solve the problems of insufficient tension, easy distortion of rolling mill speed measurement, etc., and achieve the effect that it is not easy to be distorted and the speed signal is real

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

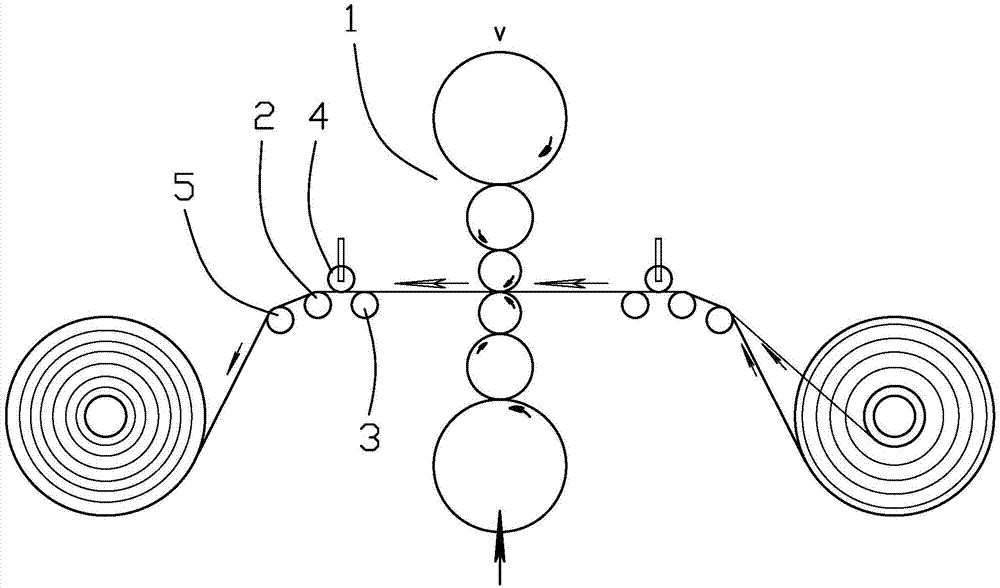

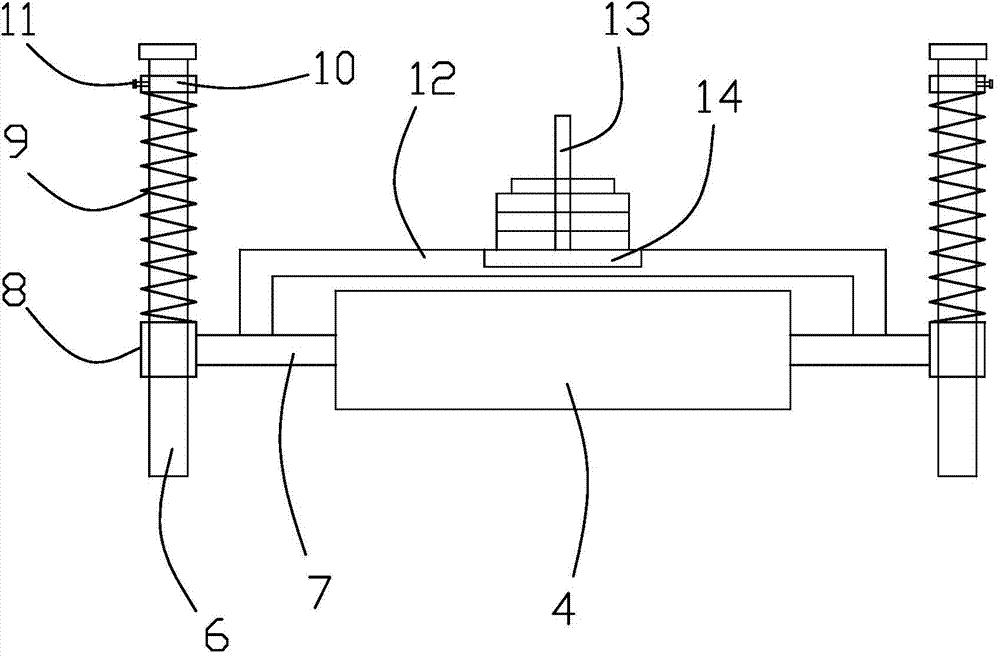

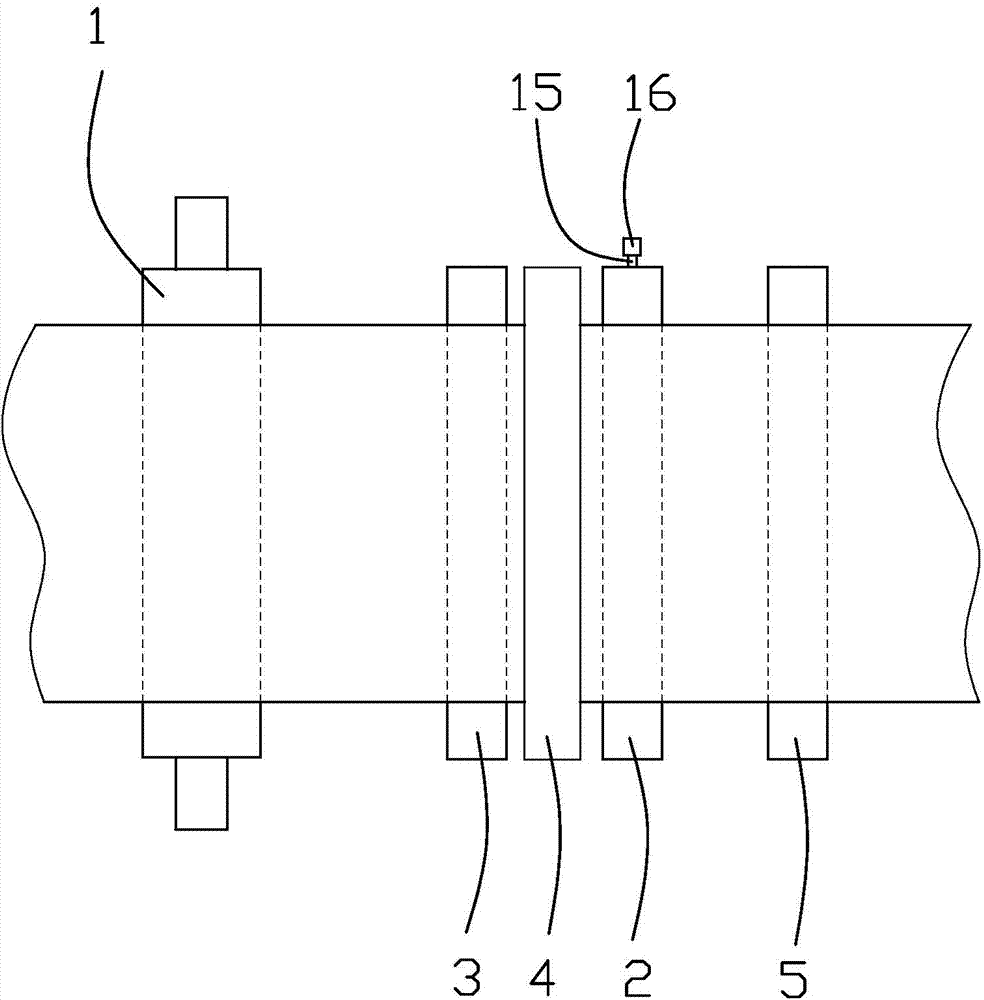

[0016] In this embodiment, a rolling mill with a speed measuring and pressure regulating structure, such as figure 1 As shown, it includes a work roll group 1, a first tension roll 2, a second tension roll 3, a pressure roll 4, and a deflector roll 5. The deflection rolls are arranged symmetrically on both sides of the work roll group, and the On one side of the roll set, the first tension roll and the second tension roll are arranged in parallel from outside to inside, and the position of the deflector roll is lower than the first tension roll and the second tension roll, and the strip passes through the work roll set, and the two sides They are respectively arranged on the second tension roller, the first tension roller and the deflection roller, and then rolled into the steel coil. Since the deflection roller is set lower than the first tension roller and the second tension roller, the strip steel is connected at the first Portions of the tension roller and the deflector r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com