Machining equipment of oil holes for bearing blocks

A technology for processing equipment and bearing housings, which is applied in the direction of metal processing equipment, metal processing machinery parts, and other manufacturing equipment/tools. The effect of reducing cost, reducing processing procedures and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

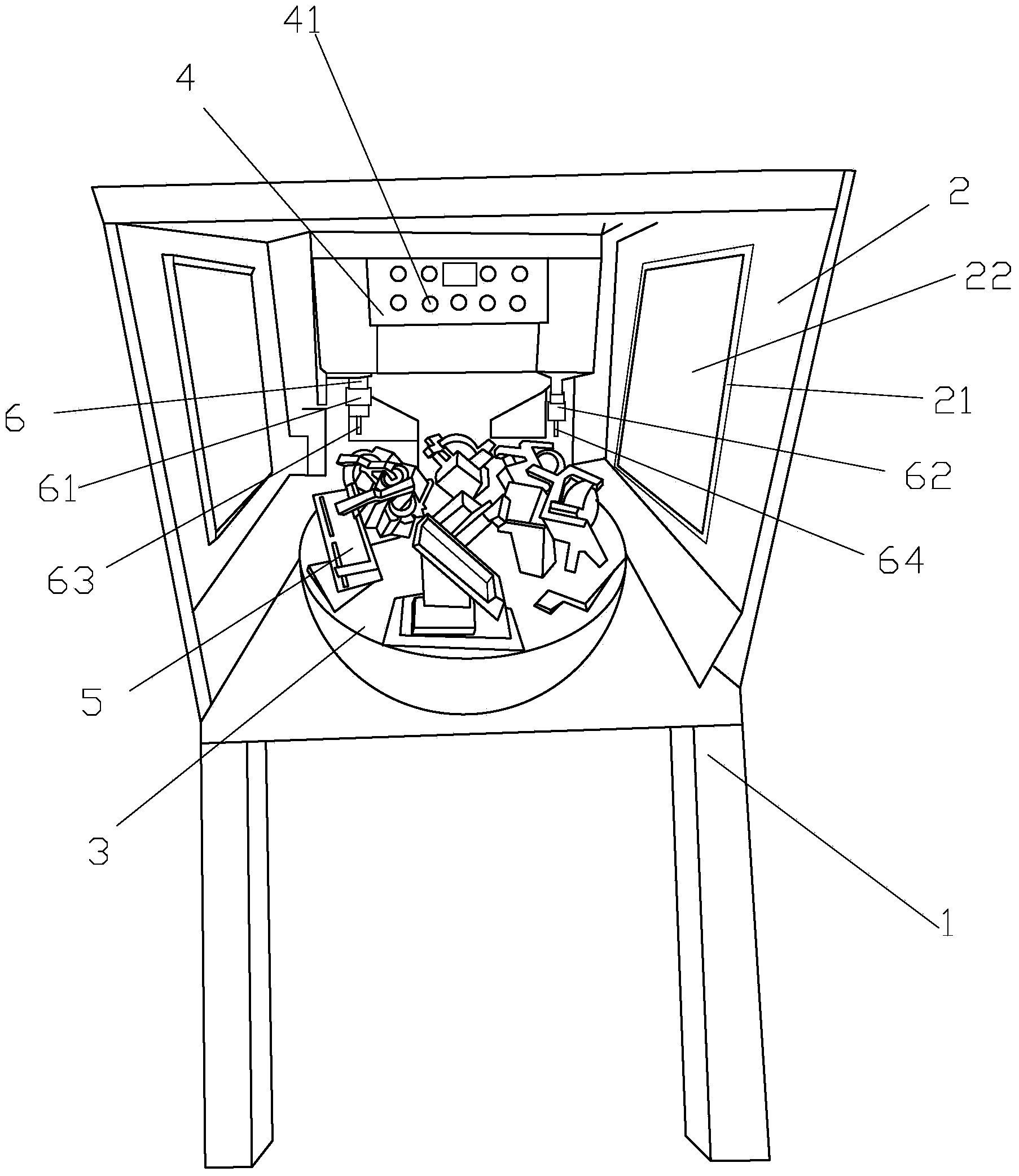

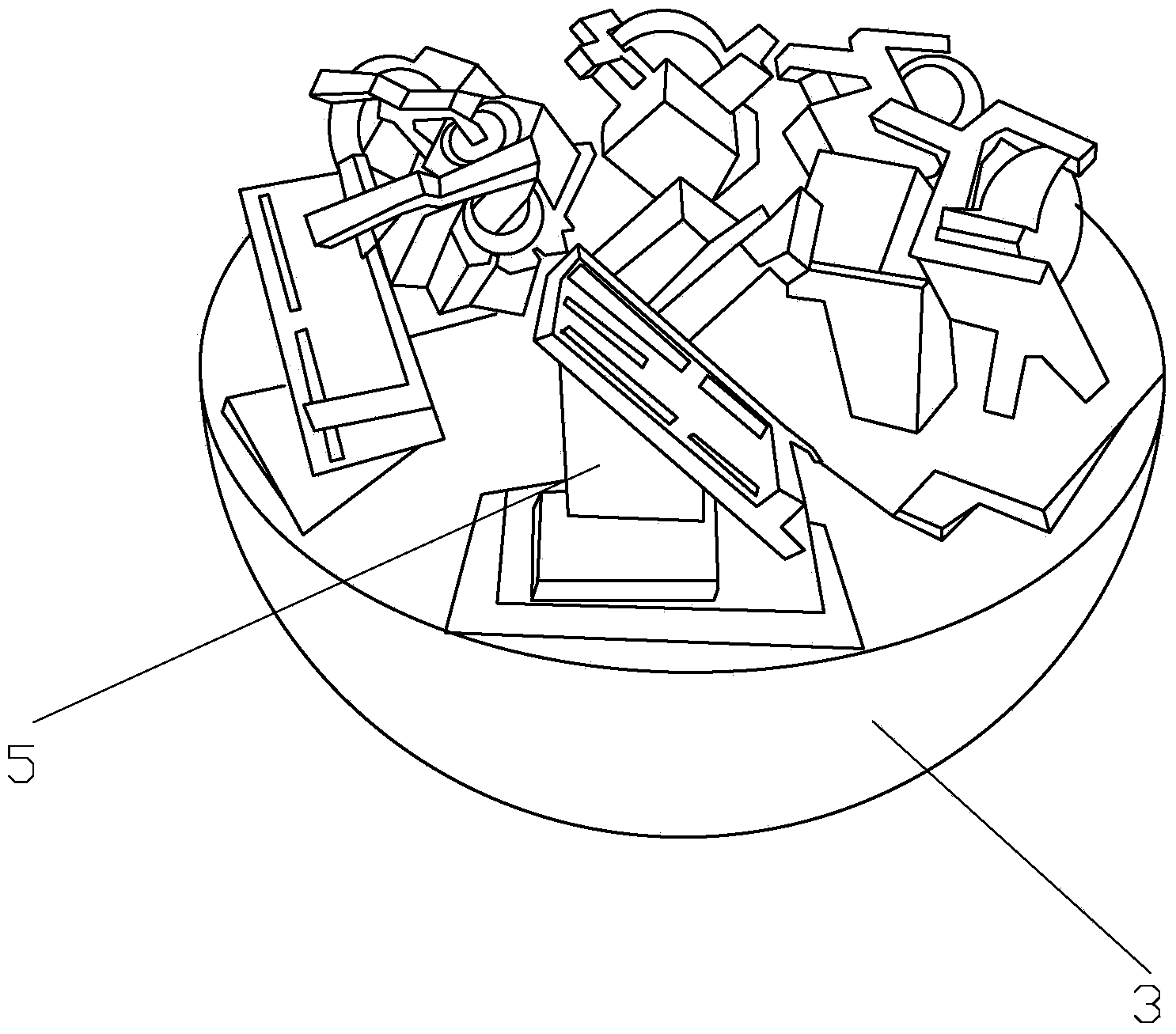

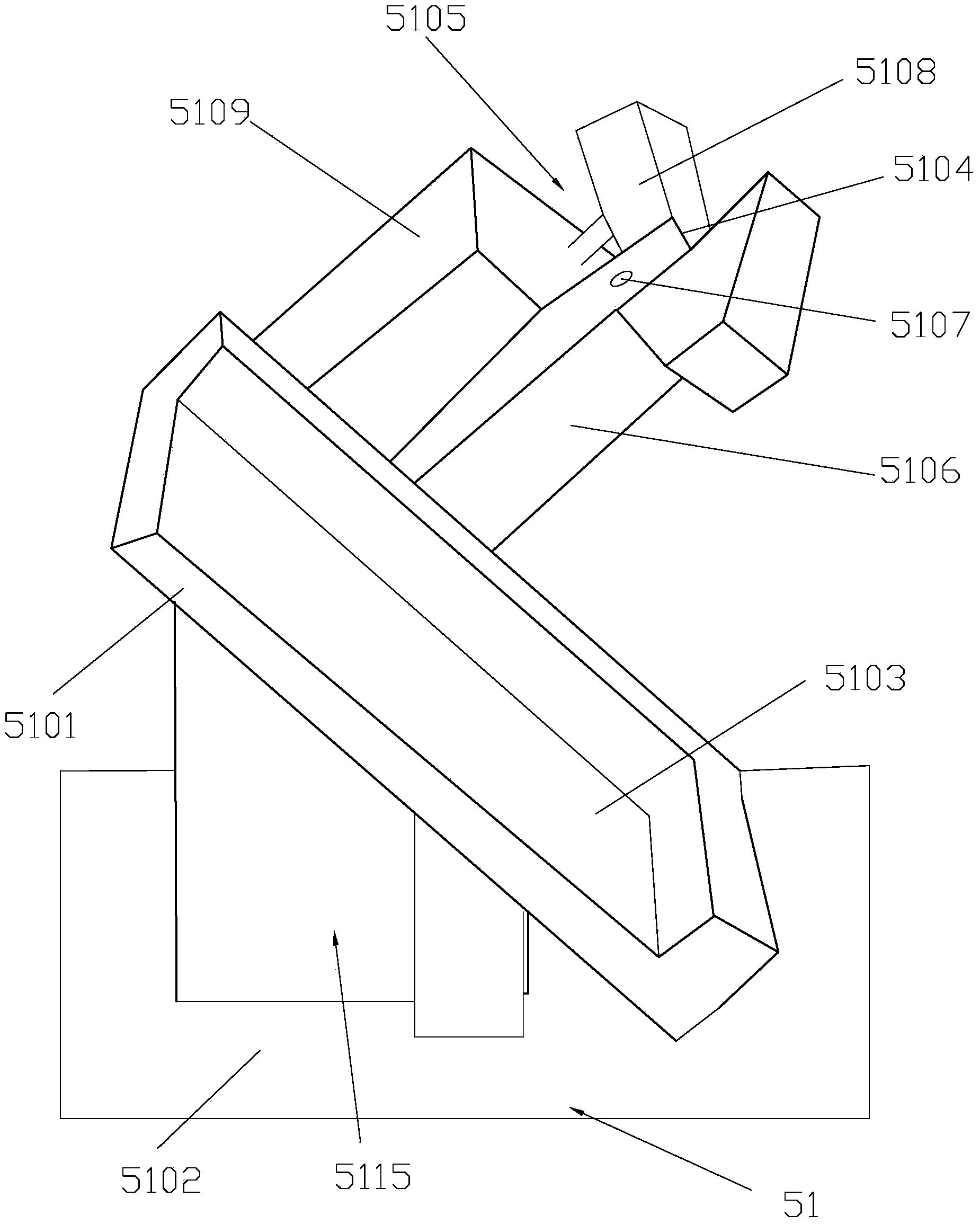

[0029] Such as figure 1 and figure 2 As shown, an oil hole processing equipment for a bearing housing includes a frame 1 and a drilling rig 6. A horizontal turntable 3 is installed on the frame 1. The turntable 3 can rotate intermittently under the drive of the power device. The power device passes through The transmission mechanism is connected with the turntable 3. The intermittent rotation of the turntable 3 stops after turning over the same angle, and turns again after staying for the same time. There are technologies, so I won't go into details here. The power unit is a stepper motor (not shown), the turntable 3 is a disc, and the surface of the turntable 3 is equiangularly provided with 4-8 detachable clamps 5, which can be conveniently fixed for different bearing seats. Carry out oil hole processing, and the setting of multiple fixtures can effectively improve production efficiency at the same time. At least one detachable fixture 5 is installed on the turntable 3. W...

Embodiment 2

[0035] Such as figure 1 and figure 2 As shown, an oil hole processing equipment for a bearing housing includes a frame 1 and a drilling rig 6. A horizontal turntable 3 is installed on the frame 1. The turntable 3 can rotate intermittently under the drive of the power device. The power device passes through The transmission mechanism is connected with the turntable 3. The intermittent rotation of the turntable 3 stops after turning over the same angle, and turns again after staying for the same time. There are technologies, so I won't go into details here. The power unit is a stepper motor (not shown), the turntable 3 is a disc, and the surface of the turntable 3 is equiangularly provided with 4-8 detachable clamps 5, which can be conveniently fixed for different bearing seats. Carry out oil hole processing, and the setting of multiple fixtures can effectively improve production efficiency at the same time. At least one detachable fixture 5 is installed on the turntable 3. W...

Embodiment 3

[0042] Such as figure 1 and figure 2 As shown, an oil hole processing equipment for a bearing housing includes a frame 1 and a drilling rig 6. A horizontal turntable 3 is installed on the frame 1. The turntable 3 can rotate intermittently under the drive of the power device. The power device passes through The transmission mechanism is connected with the turntable 3. The intermittent rotation of the turntable 3 stops after turning over the same angle, and turns again after staying for the same time. There are technologies, so I won't go into details here. The power unit is a stepper motor (not shown), the turntable 3 is a disc, and the surface of the turntable 3 is equiangularly provided with 4-8 detachable clamps 5, which can be conveniently fixed for different bearing seats. Carry out oil hole processing, and the setting of multiple fixtures can effectively improve production efficiency at the same time. At least one detachable fixture 5 is installed on the turntable 3. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com