System and method for simulating starting process states of propeller and shaft system

A state simulation and start-up process technology, applied to ship components, ships, transportation and packaging, etc., can solve the problems of inability to simulate the acceleration torque of the propeller and shafting inertia, and the difficulty of torque simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

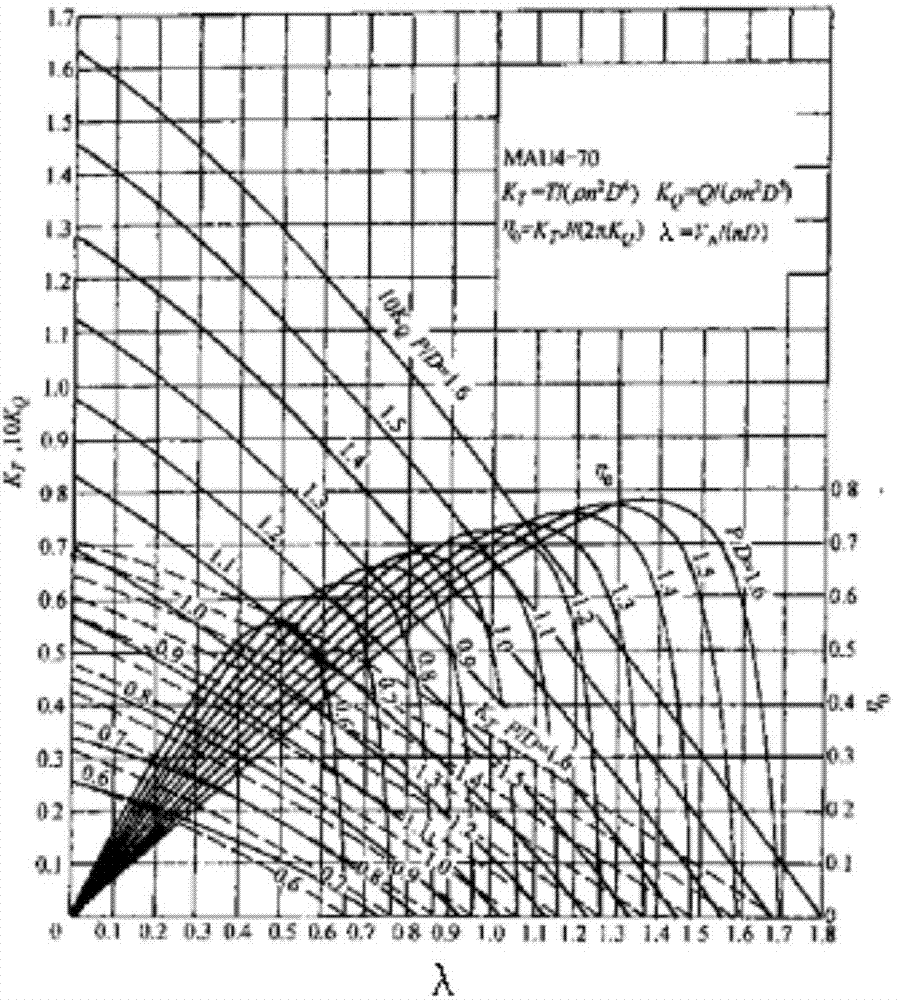

[0040] The present invention will be described in detail below with reference to the accompanying drawings and examples.

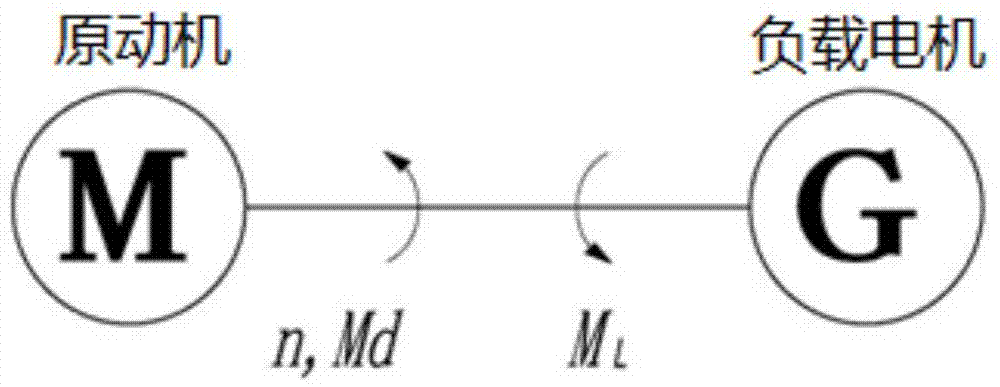

[0041] This embodiment provides a propeller and shafting start-up process state simulation system, which can realize the purpose of simulating the high-power level propeller and shafting start-up process state through a low-power level propeller and shafting.

[0042] The simulation of the starting process state of the propeller and the shafting refers to simulating the load and rotational speed of the starting process of the propeller and the shafting.

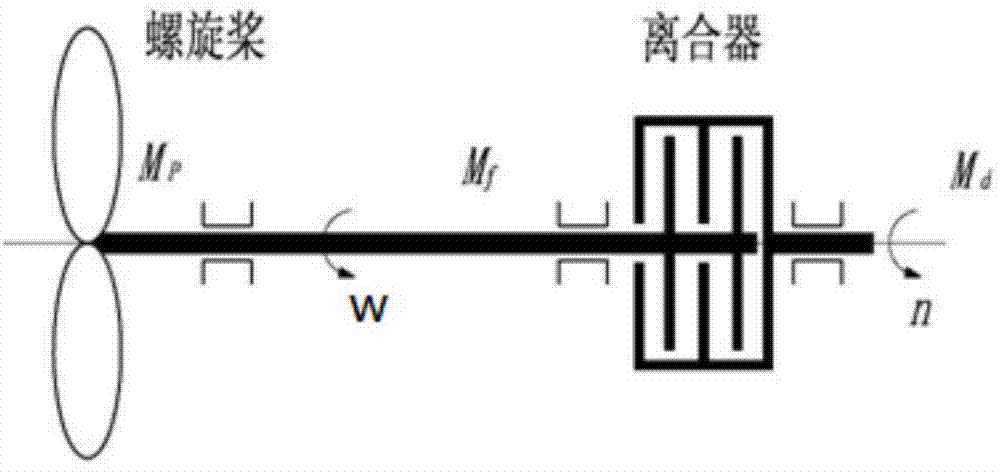

[0043] The simulation system provided by this embodiment is as image 3 As shown, it includes simulated propeller 2, simulated shaft system 3, pitch adjustment mechanism 4, thrust bearing 5, inertial unit 6, friction torque applying mechanism 7 and intermediate bearing 8; the peripheral equipment is propeller pool 1, clutch 9, shaft coupling device 10 and propulsion motor 11.

[0044] Among them, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com