External mixing type glass polishing combustor

A burner and glass technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of shortening the service life of the polished burner head, heat generation of the polished burner head, and tempering of the polished burner, etc., to achieve Avoid tempering phenomenon, reduce harmful gas, and improve combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

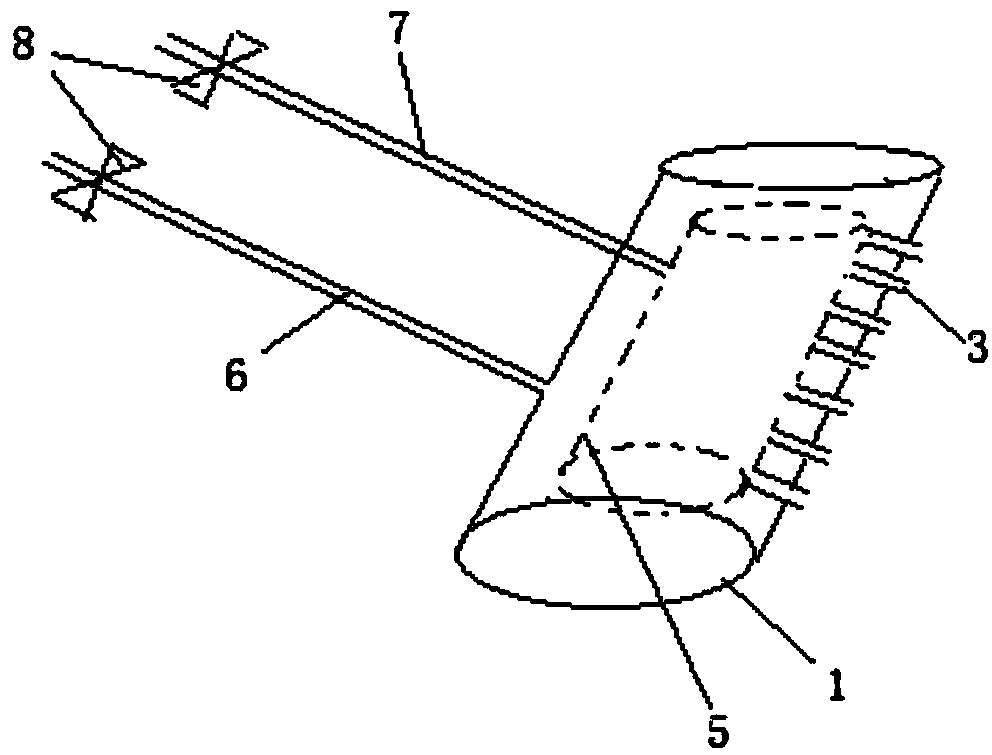

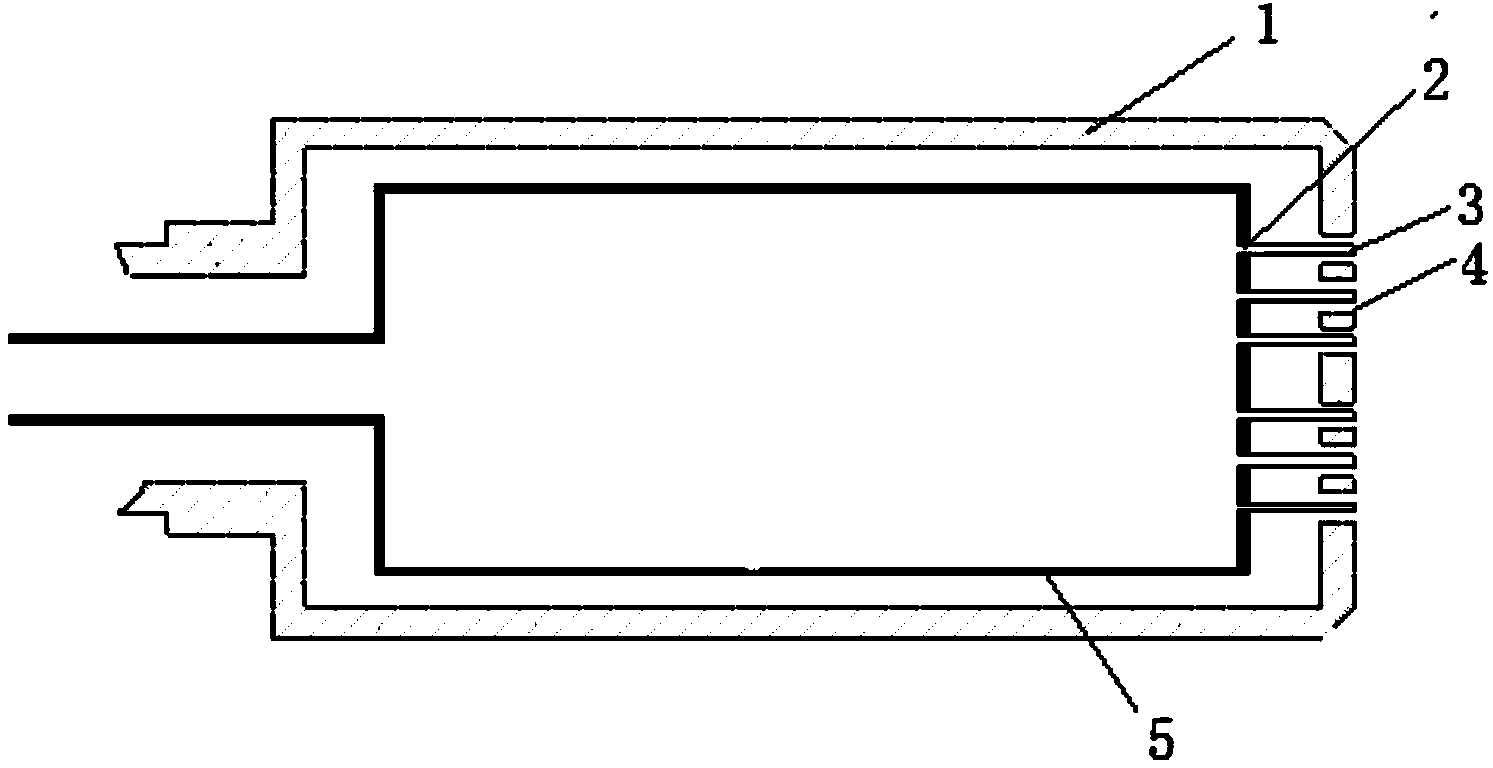

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

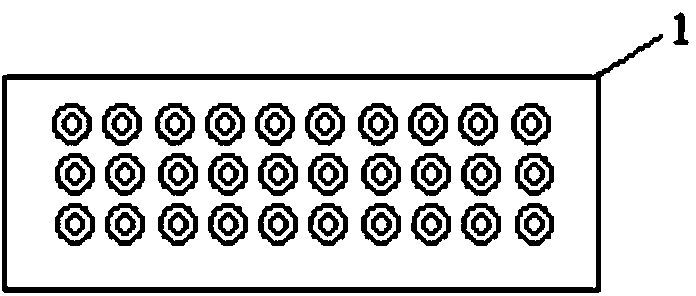

[0037] An external mixing glass polishing burner, including an inner cavity tube 5 and an outer cavity tube 1 set together, a first combustion medium channel is formed in the inner cavity tube 5, and a second combustion medium channel is formed between the inner cavity tube 5 and the outer cavity tube 1 Combustion medium passage; the first combustion medium passage and the second combustion medium passage are independent of each other, the inner cavity tube 5 is provided with a first combustion medium inlet, and the outer cavity tube is provided with a second Combustion medium inlet; the inner tube 5 is provided with a number of injection holes I2, and the outer tube is provided with a number of injection holes II4, and the injection holes I2 and injection holes II4 are coaxially arranged; the present invention adopts an external gas mixing method, With sufficient oxygen suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com