Method and system for recovering and utilizing flue gas waste heat of regenerative cremation machine

A technology of flue gas waste heat and cremation machine, which is applied in the methods of incinerating corpses, combustion methods, lighting and heating equipment, etc., can solve the problems of site limitation and high energy consumption, achieve convenient disassembly and installation, improve heat conversion rate, and design structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing, the specific embodiment of the present utility model is described further.

[0061] The following examples are only examples for clearly illustrating the utility model, rather than limiting the implementation of the utility model. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can be made, and these obvious changes or changes that belong to the spirit of the present invention are still protected by the present invention within range.

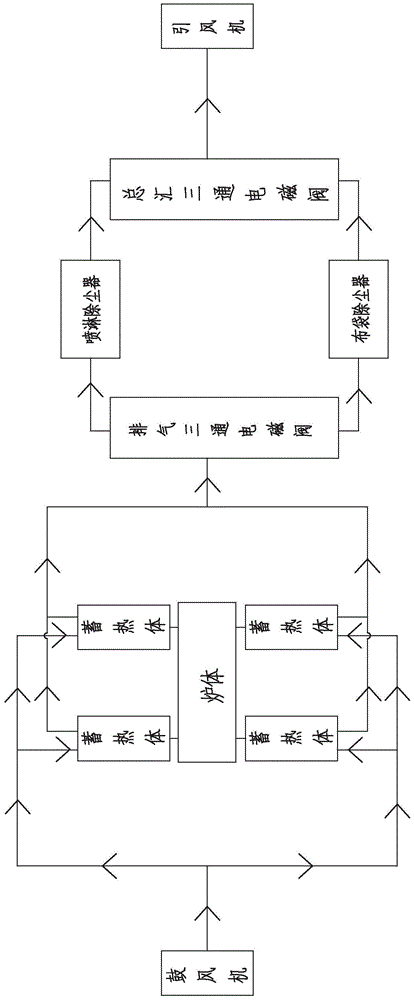

[0062] An embodiment of a method for recovering and utilizing flue gas waste heat of a regenerative cremator of the present invention is as follows:

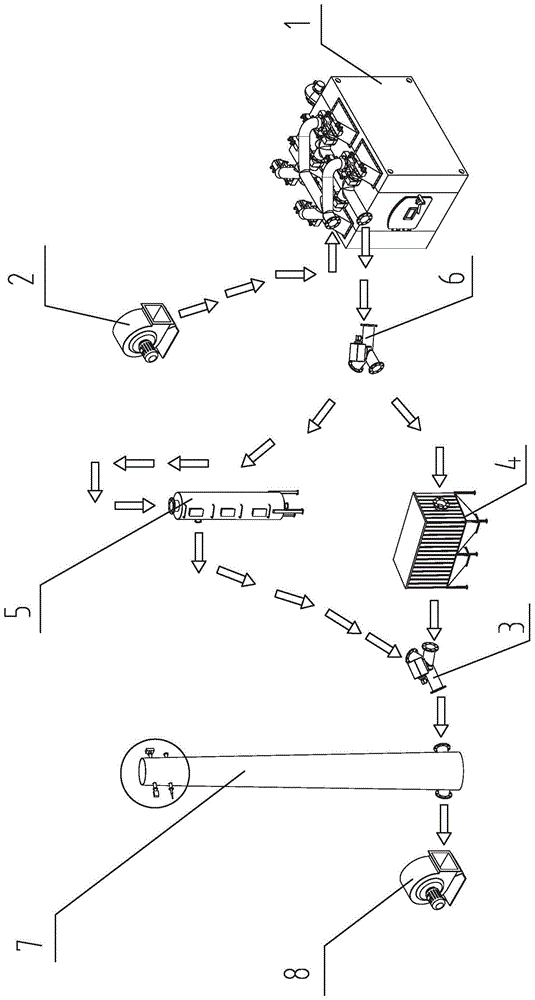

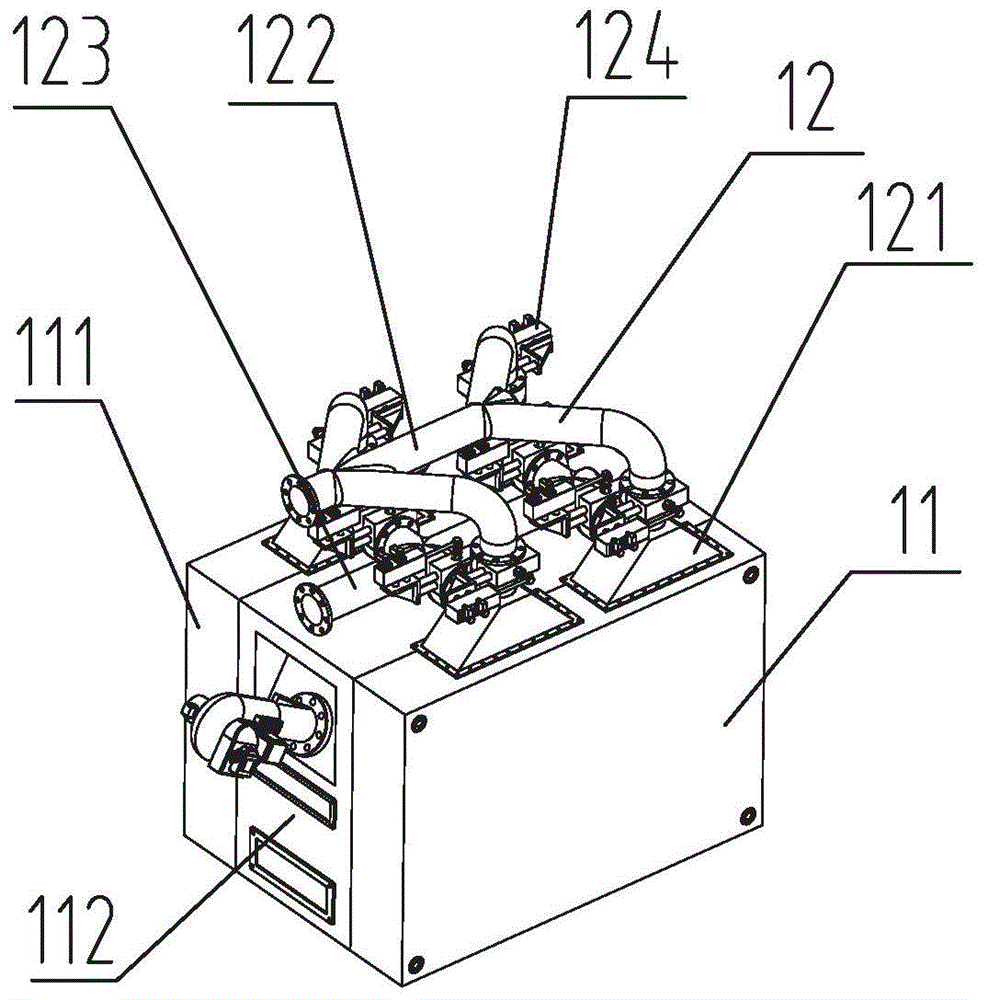

[0063] Such as Figure 1-14 As shown, a method for recovering waste heat from flue gas of a regenerative cremator, the method comprising:

[0064] Step 1, send air or supporting gas into the air intake assembly 122 through the blower 2, the air or supporting ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com