Capacitive rotary position encoder and capacitive rotary position detection method

A technology of rotating position and encoder, which is applied in the direction of using electric device, converting sensor output, and using electric/magnetic device to transmit sensing member, etc., to achieve the effect of determining the rotating position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

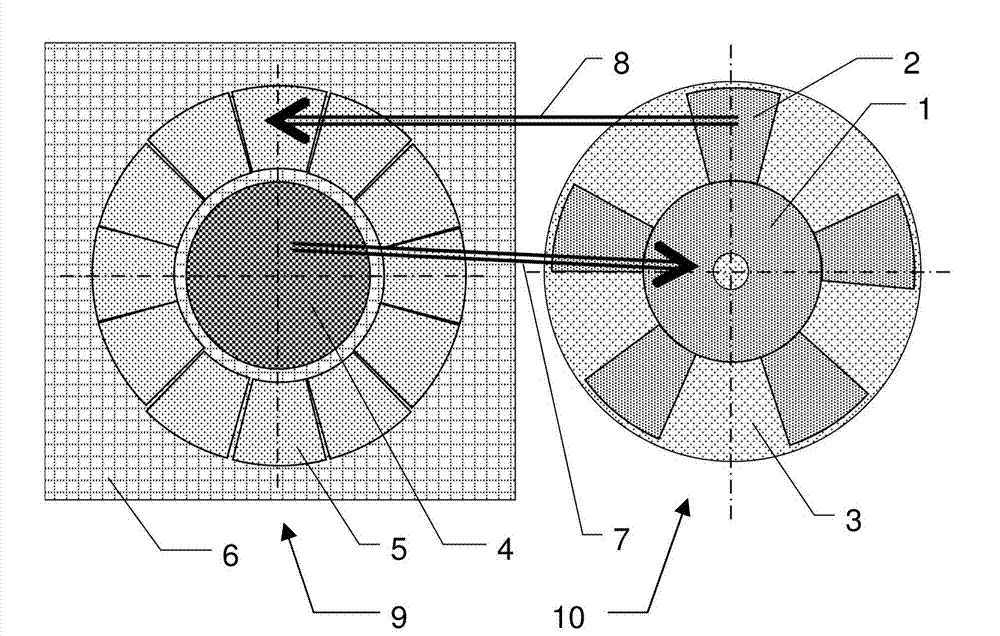

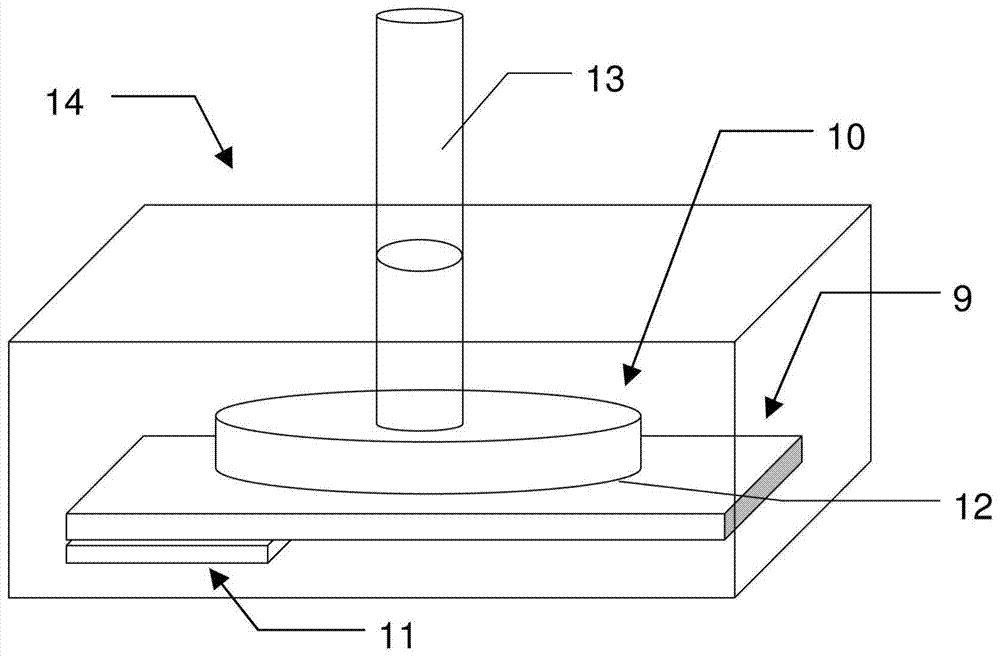

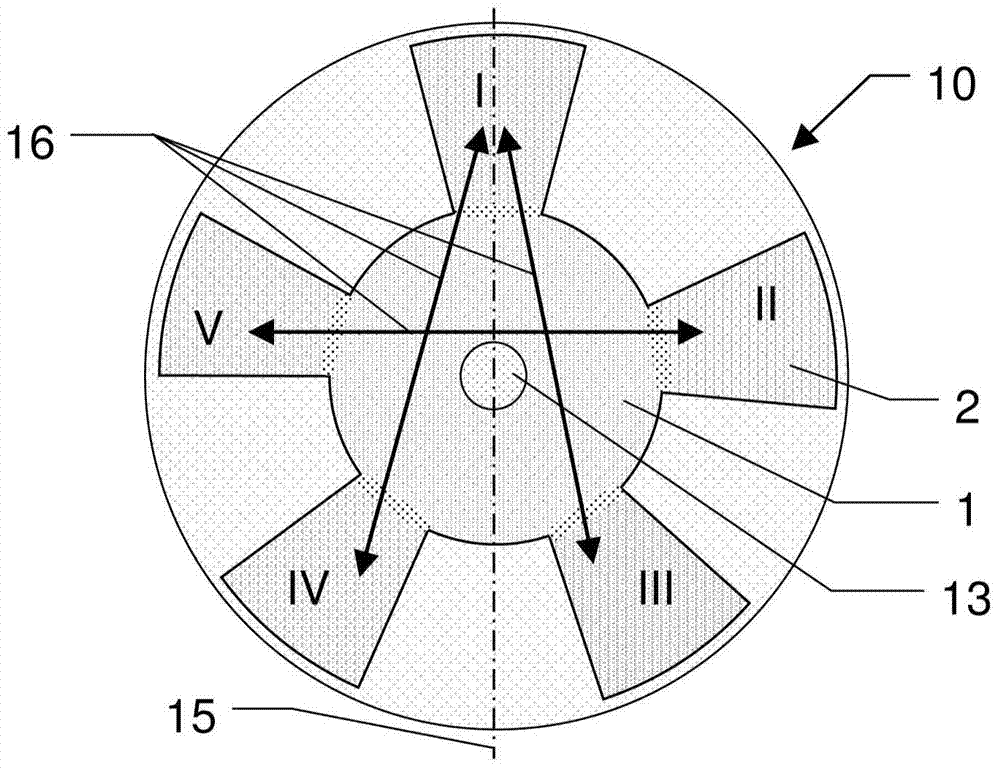

[0061] figure 1 One embodiment of a capacitive rotary position encoder according to the invention for the absolute determination of the rotational position about a rotational axis is shown. This rotary position encoder has a transceiver unit 9 comprising a first arrangement of N conductive capacitive sensitive areas 5, which are implemented as angular nodes with a predetermined angular range and are uniformly distributed over the periphery part. In this case, the predetermined angular range is in particular approximately 360° / N, so that it can be deduced that the spacing between the sensitive areas 5 is substantially negligibly small, in particular smaller than said angular range several orders of magnitude.

[0062] Furthermore, the transceiver unit 9 has an electrically conductive reference area 4 and an evaluation circuit by means of which the capacitance value between the reference area 4 and one of the sensitive areas 5 can be determined.

[0063] In this case, the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com