Hydrofoil blade top gap and attack angle adjusting system for water tunnel experiment

A technology of experimental water and blade tip clearance, which is applied in the fields of ocean ship engineering, water conservancy and hydropower engineering, can solve the problems of high experimental cost and complex structure, achieve easy disassembly and movement, simple and reliable sealing device, and avoid performance degradation of water tunnel experiments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

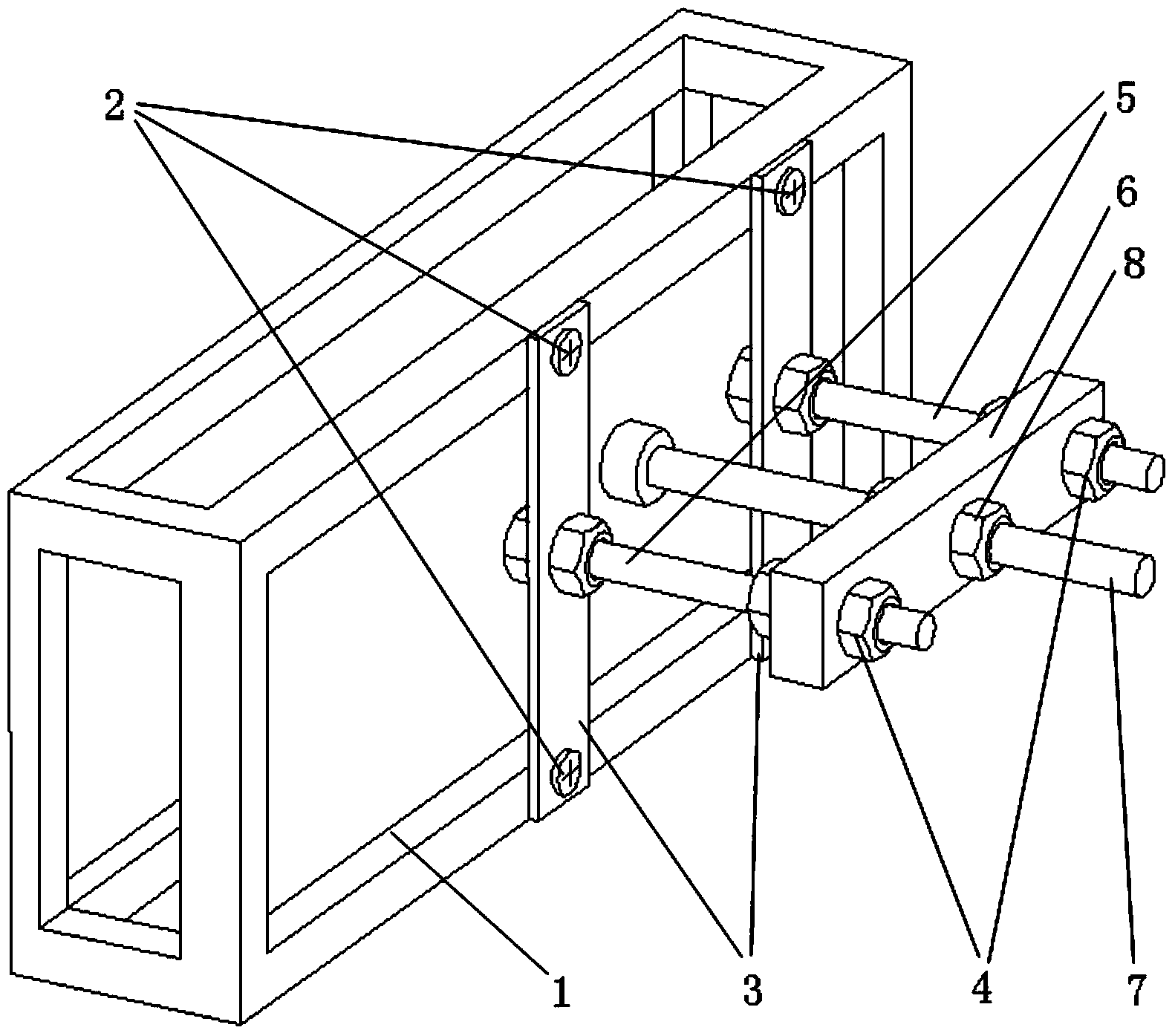

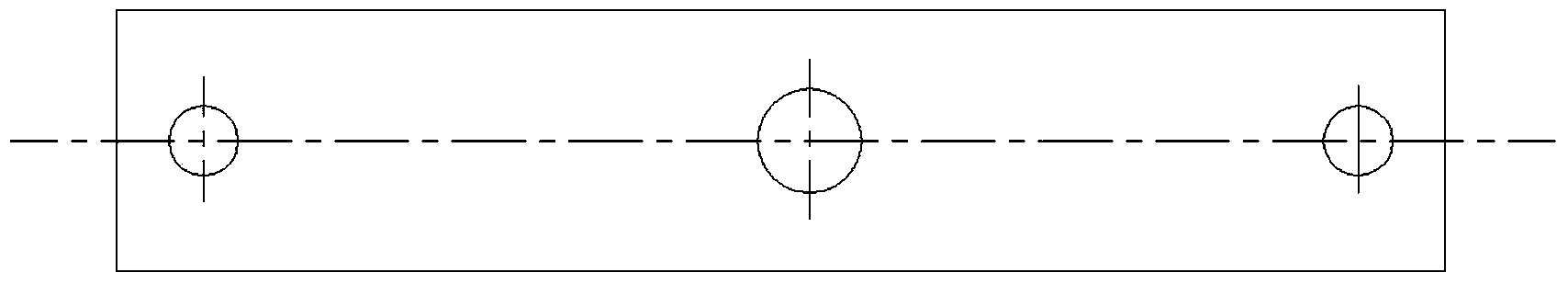

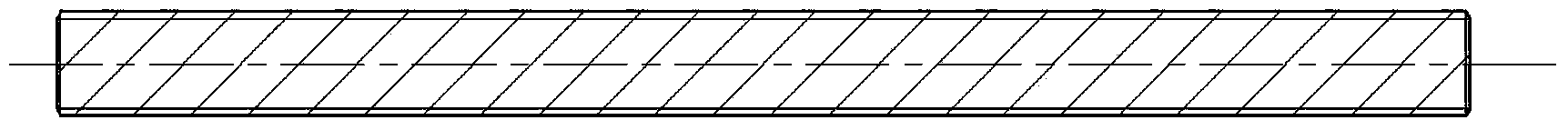

[0034] Such as figure 1 As shown, the hydrofoil tip clearance and angle of attack adjustment system of the present invention consists of a water hole observation section 1, a fixed plate 3, a positioning nut 4, a support rod 5, a positioning block 6, a hydrofoil connecting rod 7, an angle of attack adjustment nut 8 and Composed of elastic sealing structure. Such as figure 2 As shown, the central part of the fixing plate 3 has a through hole. Such as image 3 As shown, the surface of the support rod 5 is threaded. Such as Figure 4 Shown, one end of the surface of the hydrofoil connecting rod 7 has no thread, and one end has thread. Such as Figure 5 As shown, the two ends and the center of the positioning block 6 are provided with through holes. Connection relationship: two fixed plates 3 are fixed on the observation section 1 of the water tunnel by riveting or welding at a certain distance; two support rods 5 pass through and are vertically fixed on the two fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com