Method for Determining the Molecular Structure of Additives for Nickel Removal in Heavy Oil

A molecular structure and additive technology, applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of fast deactivation of HDM catalyst, difficult disposal of waste catalyst, huge equipment investment, etc., and achieve fast and accurate calculation results. A large number of experiments, the effect of saving experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

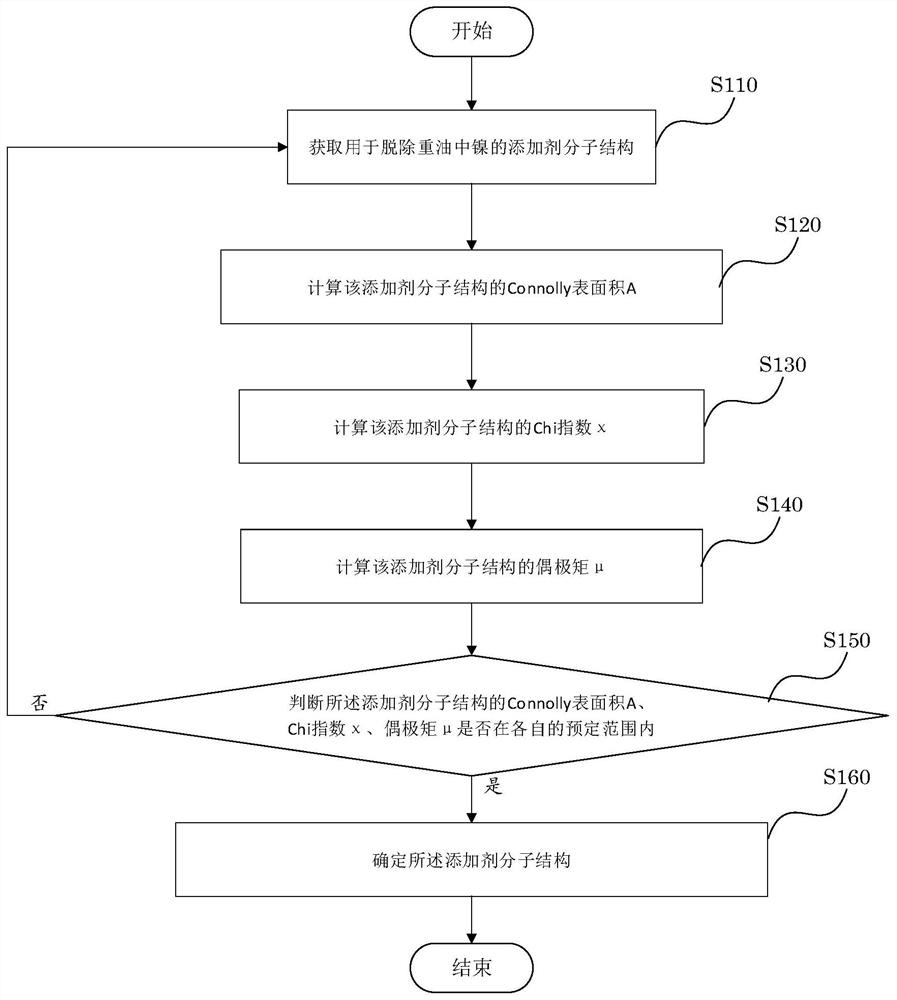

[0037] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

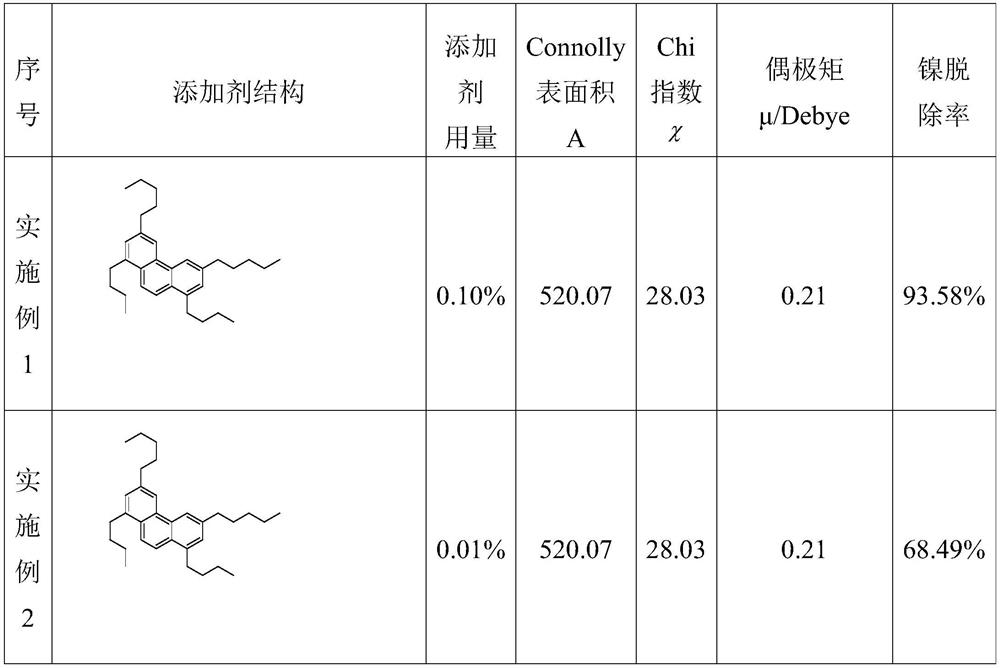

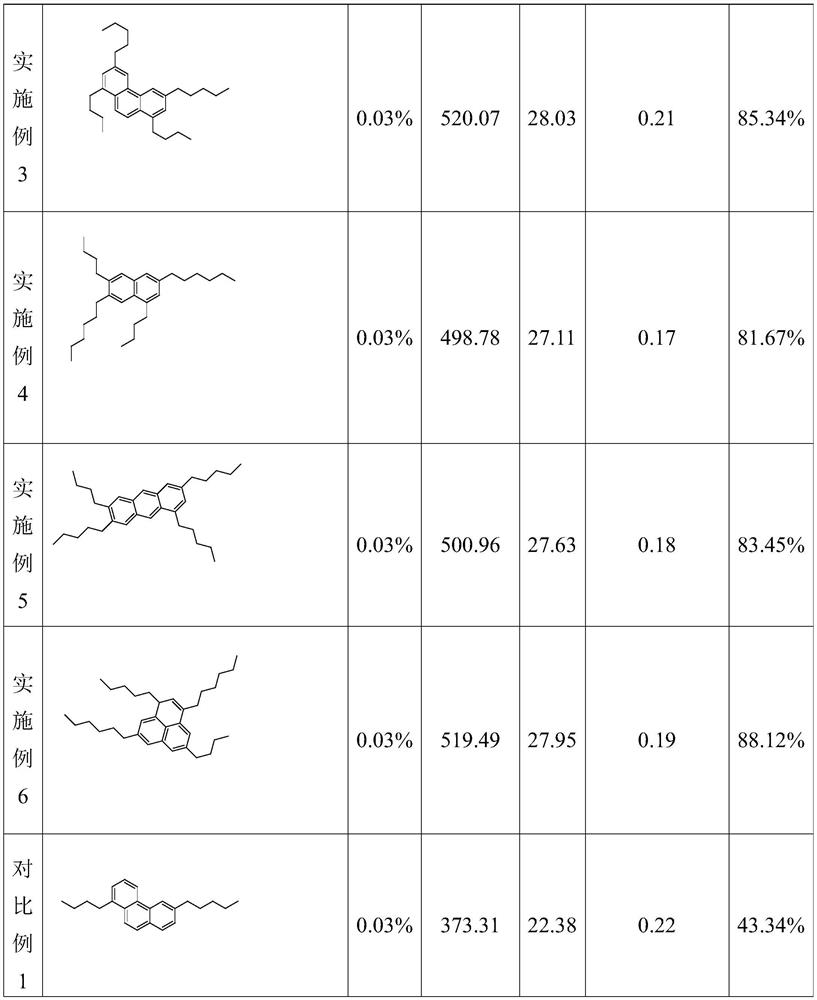

[0038] An embodiment of the present invention provides an additive for removing nickel in heavy oil, the molecular structure of the additive satisfies the following conditions:

[0039] The Connolly surface area A of the molecular structure of the additive is in

[0040] The Chi index χ of the molecular structure of the additive is in the range of 25 to 30;

[0041] The dipole moment μ of the molecular structure of the additive is in the range of 0.1-0.6 Debye.

[0042] The nickel in the heavy oil is removed in a demetallization tower by adding additives with a molecular struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com