Local discharging detection method of insulating draw bar based on electric field calculation and X-ray excitation

A technology for partial discharge detection and insulating tie rods, which is used in circuit breaker testing, dielectric strength testing, material analysis using radiation, etc. The effect of anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

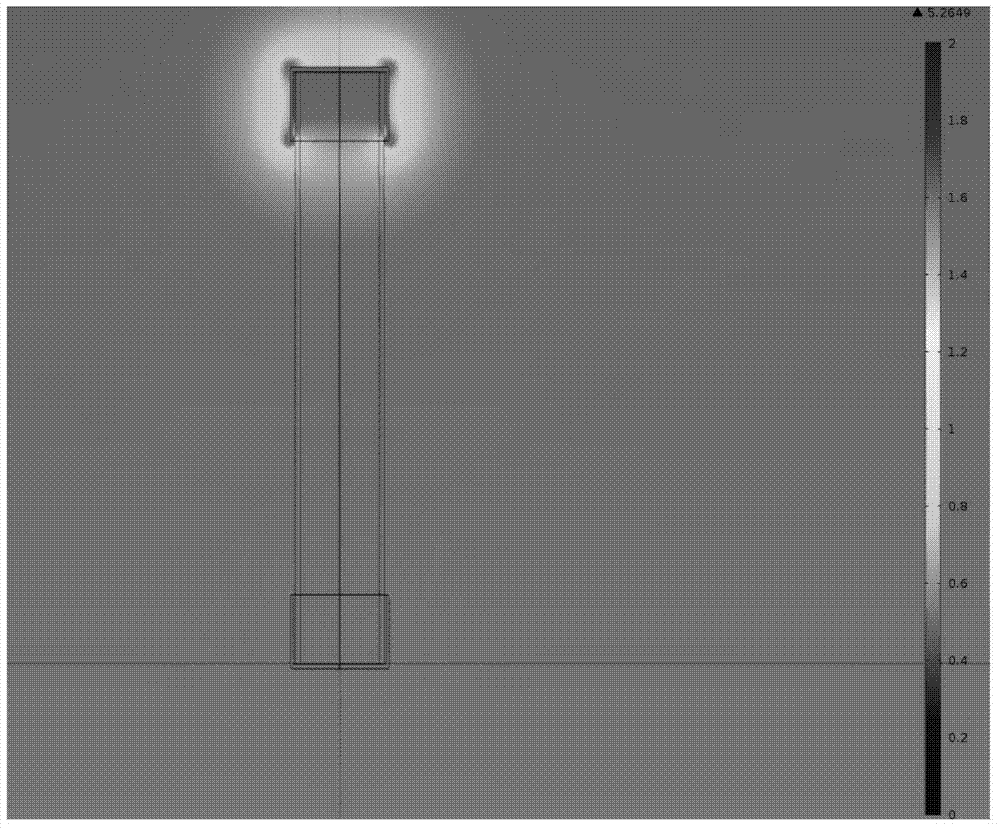

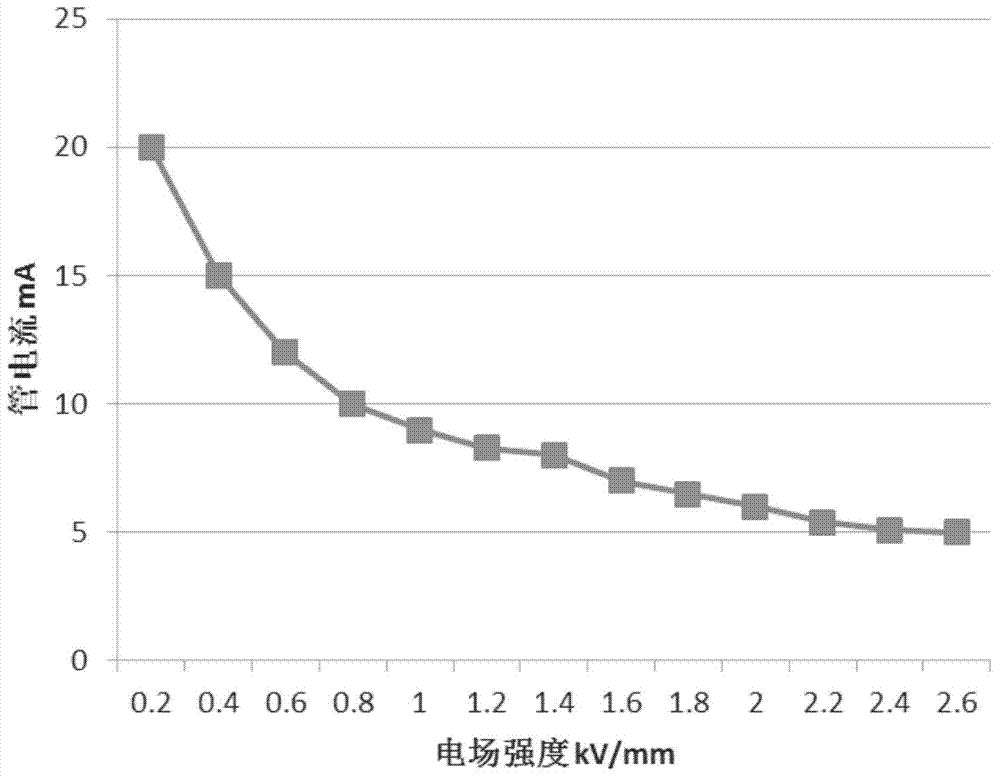

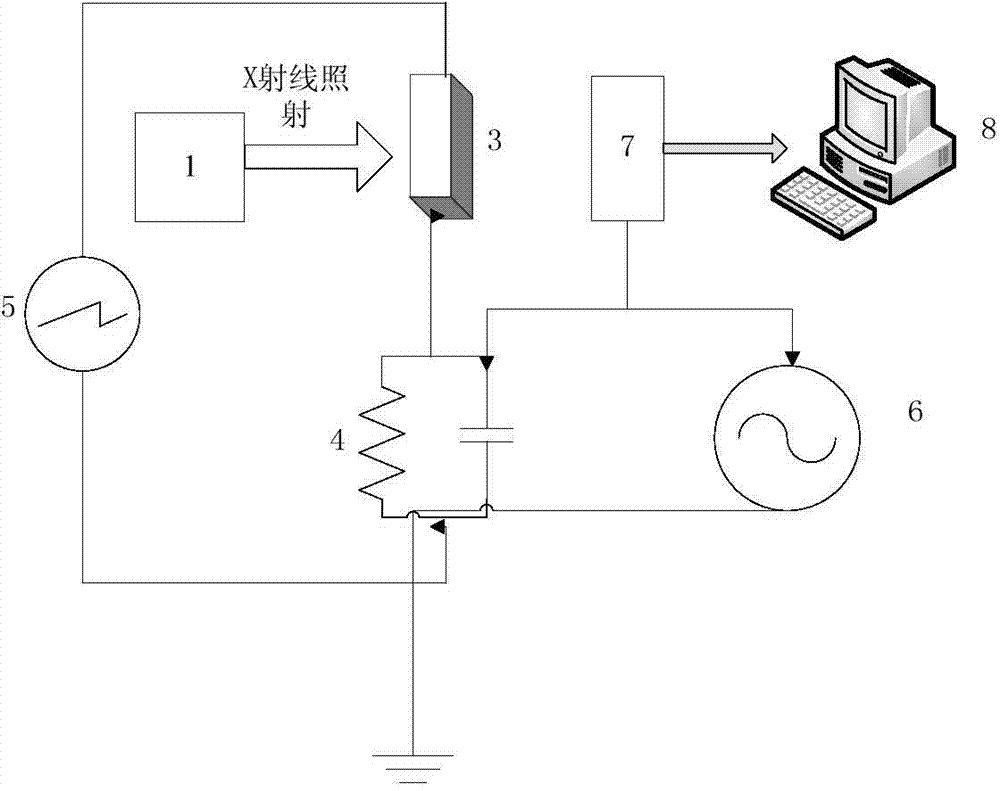

[0023] When performing partial discharge detection on the insulating pull rod, first put the insulating pull rod into the test tank, pressurize both ends of the insulating pull rod and perform partial discharge detection. At rated voltage, the electric field and voltage distribution are as follows figure 1 Shown: the electric field distribution of the insulating tie rod is high at both ends and low in the middle, especially the electric field at the high voltage end is higher, the highest is 1.08kV / mm, the lowest electric field in the middle is 0.07kV / mm, and the electric field at the ground end rises slightly It is 0.14kV / mm. If the internal defect of the insulating rod is located in the middle and lower part (close to the ground electrode), it is difficult to detect the partial discharge. Therefore, the present invention proposes to irradiate different parts of the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com