Self-cleaning insulator

A self-cleaning technology for insulators, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of poor anti-pollution ability of composite insulators, and achieve the effect of saving manpower and material resources and preventing rain flash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

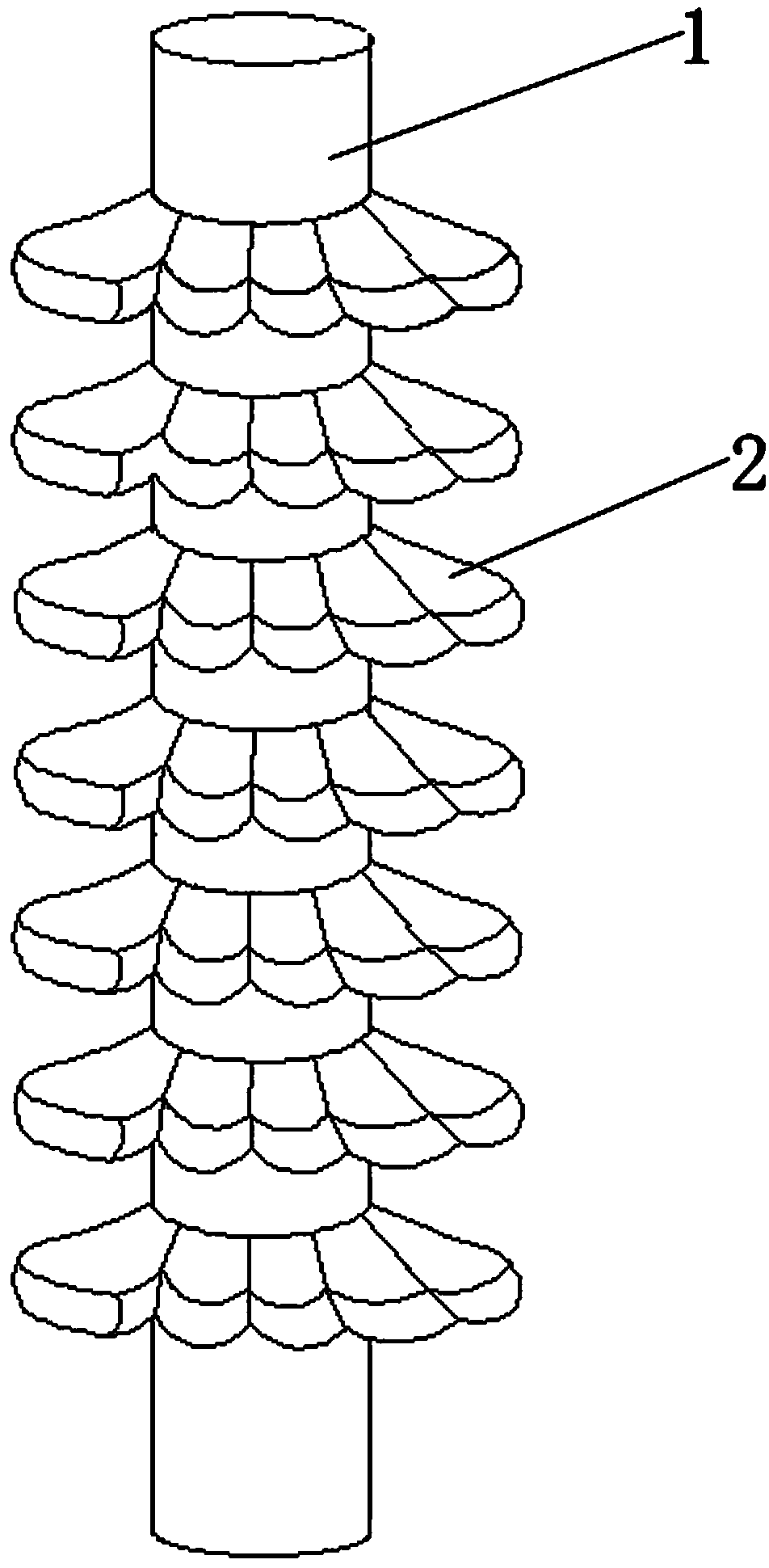

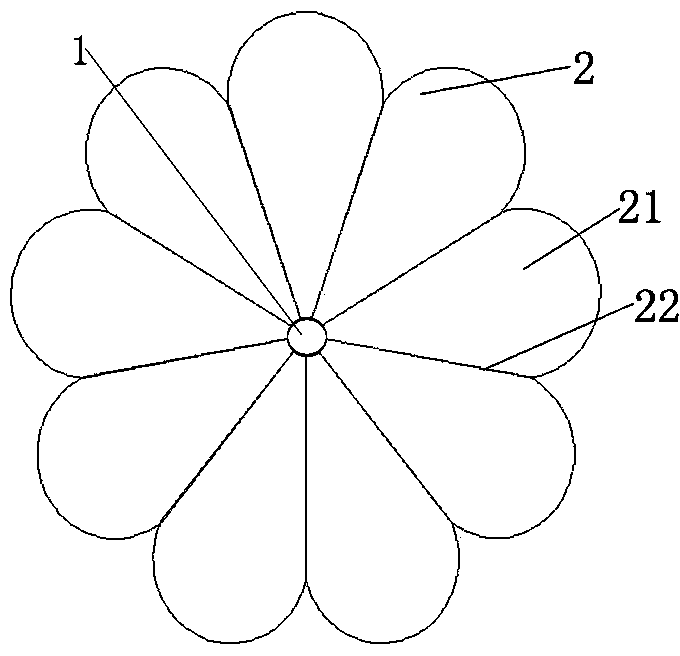

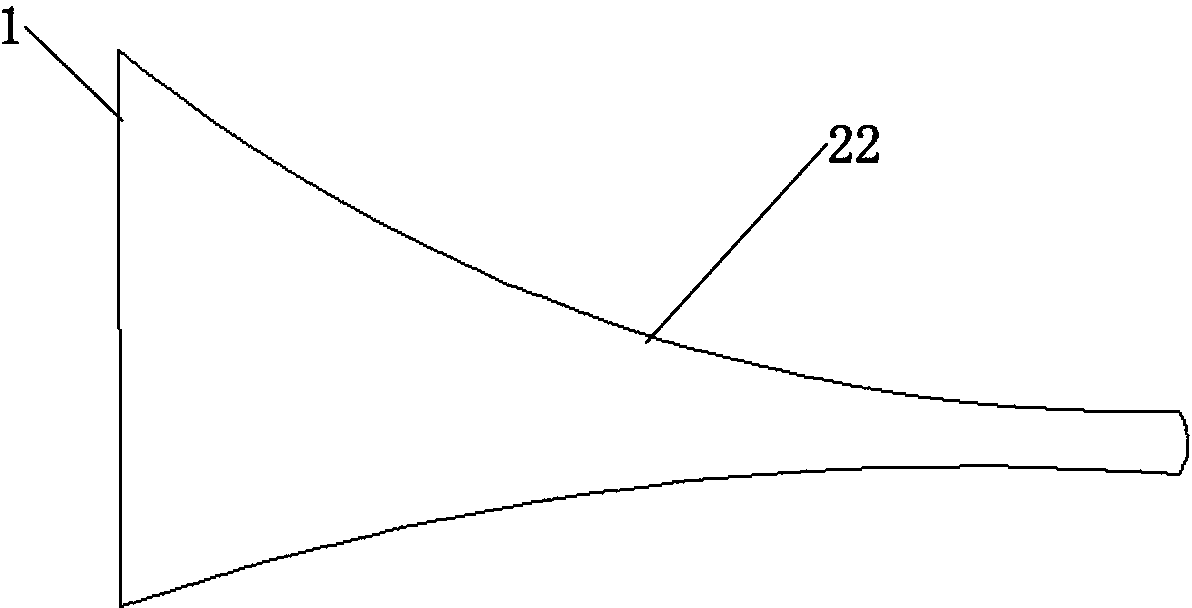

[0013] Such as Figure 1-Figure 4 The insulator designed in the present invention includes an insulator shed 2 and an insulator column 1. The insulator shed 2 is composed of a plurality of sector units 21; the junction of adjacent sector units 21 forms a ridge 22, and the upper surface of the sector unit 21 The height from the insulator column 1 to the edge decreases in order (such as image 3 ), and the cross section of the upper surface of the sector unit 21 is an arc with a high ridge 22 and a concave middle (such as Figure 4 ).

[0014] At least two insulator umbrella skirts 2 may be provided.

[0015] A ridge is formed at the junction of adjacent sector-shaped units adopted by the present invention, the middle of the sector-shaped units is recessed downward, and the center position is higher than the edge position. Because the dust will not accumulate in the spine, it will accumulate in the recessed part. When there is rain, the accumulated dust can be washed away, thus ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com