Power Transformer with Dual Electrostatic Screens

A technology of power transformers and electrostatic screens, applied in the field of transformers, can solve problems such as hidden dangers at the end of outgoing lines, imperfection of D-connected transformers, and easy breakdown of winding insulation, so as to improve short-circuit resistance and reduce labor and operation complexity. , Guarantee the effect of performance and operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

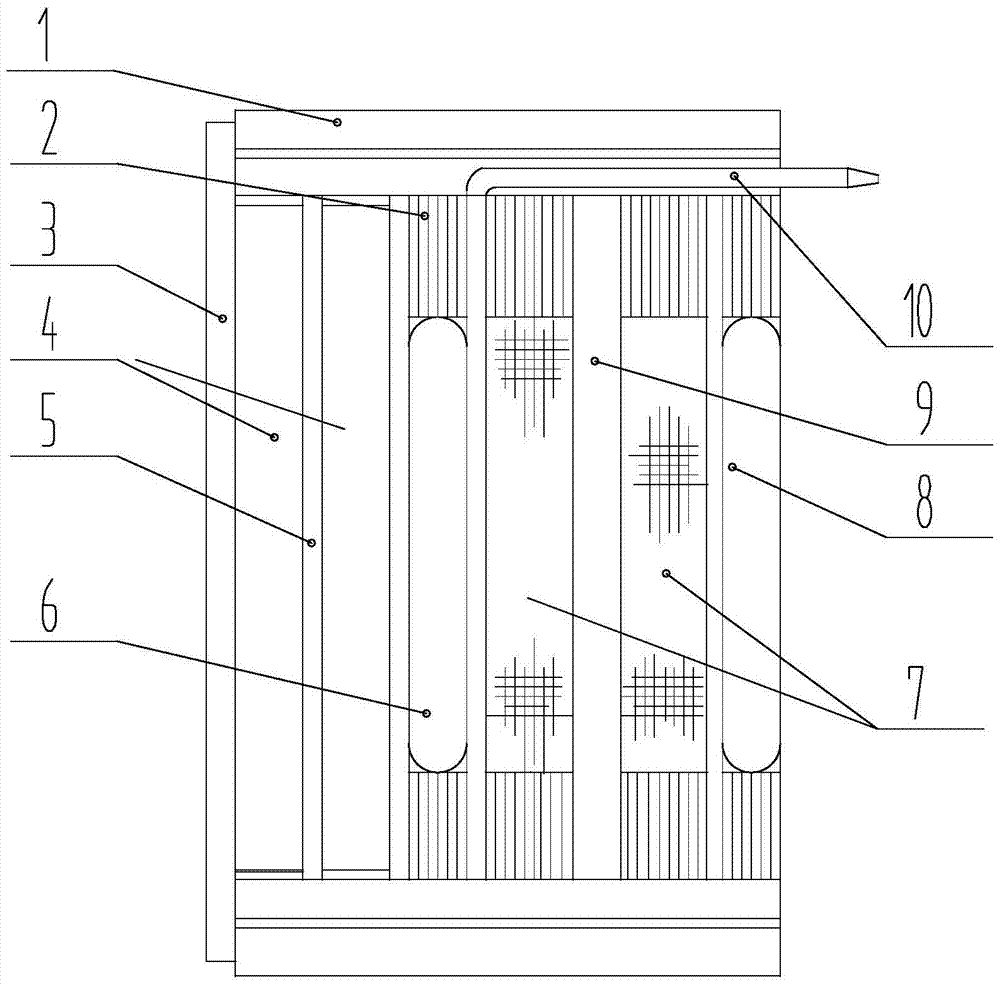

[0016] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the present invention includes a high-voltage coil winding 7, and the inside and outside of the high-voltage coil winding 7 are respectively provided with a first electrostatic screen 6 and a second electrostatic screen 8, and the first electrostatic screen 6, the second electrostatic screen 8 and the high-voltage line The head and the end of the coil winding 7 are connected. The first electrostatic screen 6 and the second electrostatic screen 8 clamp the high-voltage coil winding 7 inside and outside. When the high-voltage coil winding is D connected, the overvoltage borne by the head and the end of the high-voltage coil winding 7 can pass through the two electrostatic screens. device to reduce the high voltage on the starting and ending ends, improve the electric field distribution, connect the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com